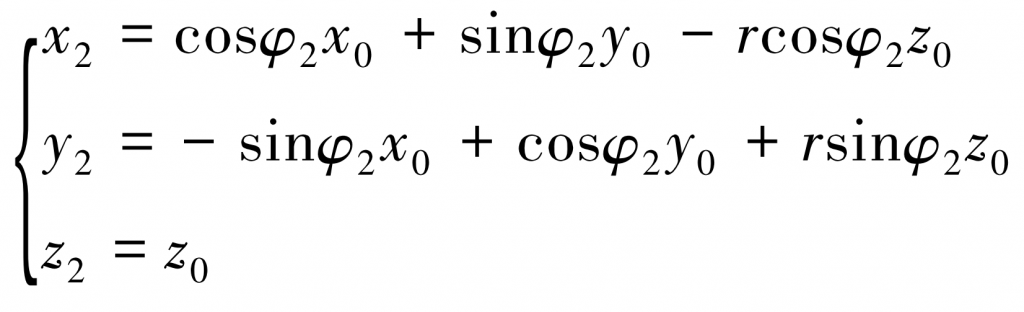

The single side tooth surface of circular arc tooth profile cylindrical gear is composed of multiple curved surfaces. The establishment of the three-dimensional model of the tooth surface needs to calculate the discrete points on the tooth surface according to the formula, generate the curve from the discrete points, and then generate the tooth surface from the curve. The more discrete points of the established tooth surface, the higher the accuracy of the final generated tooth surface.

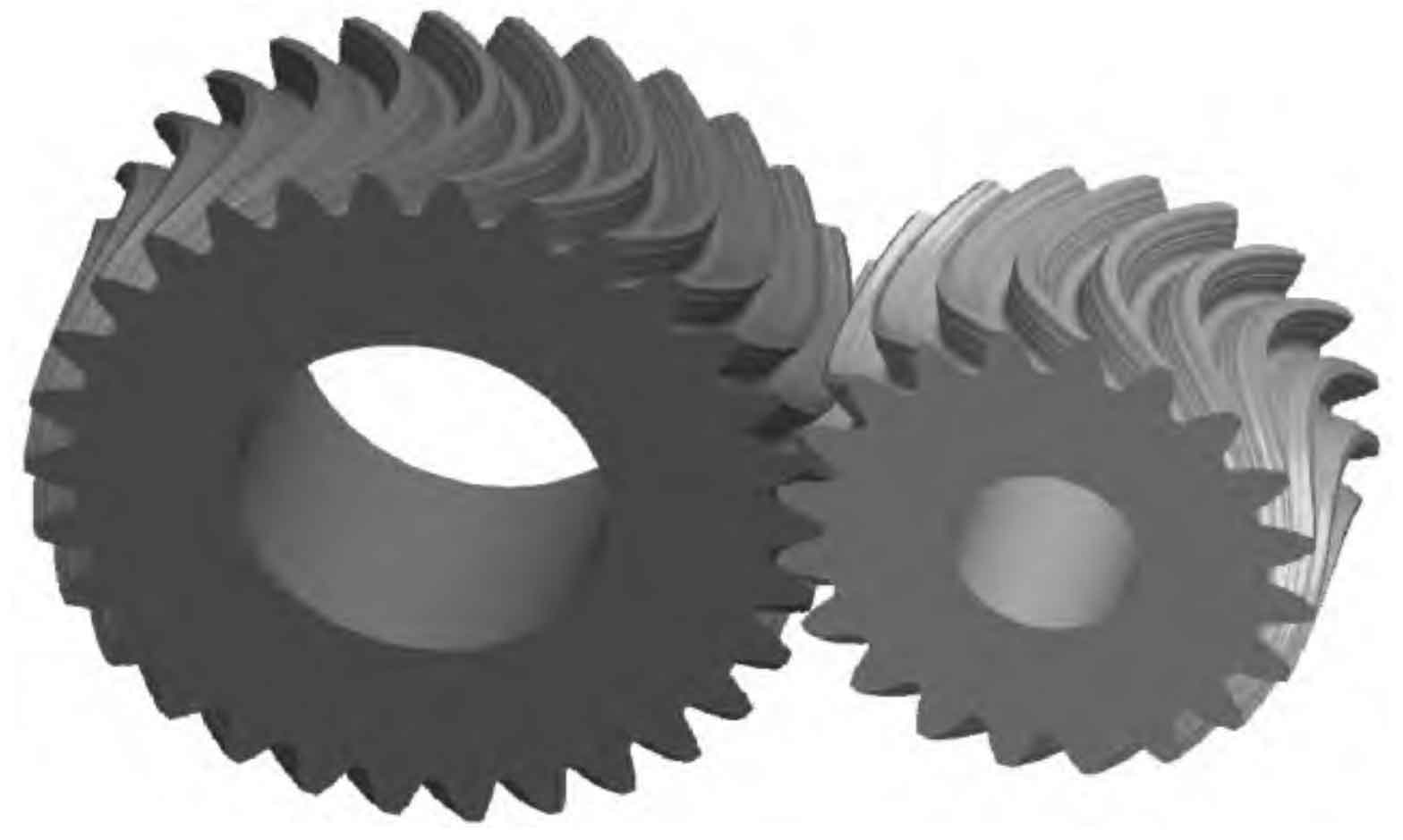

The number of teeth of pinion and big gear is 20 and 30 respectively, the modulus is 8, and the tooth width is 120 mm. The milling cutter head for machining is 6 inch. The discrete points of the tooth surface are calculated by programming with MATLAB software, and the coordinates of the discrete points are input into the pro /engineer 3D design software. In the software, the curve is generated from the discrete points, and then the surface is generated from the curve.

After generating all the surfaces of the tooth surfaces on both sides of the tooth, a single tooth of the gear is generated from the surface, and finally all the teeth of the gear are generated through the array. In this paper, double circular arc tooth profile and four circular arc tooth profile gears are established at the same time, in which the four circular arc tooth profile circular arc tooth line cylindrical gear is established as shown in the figure.