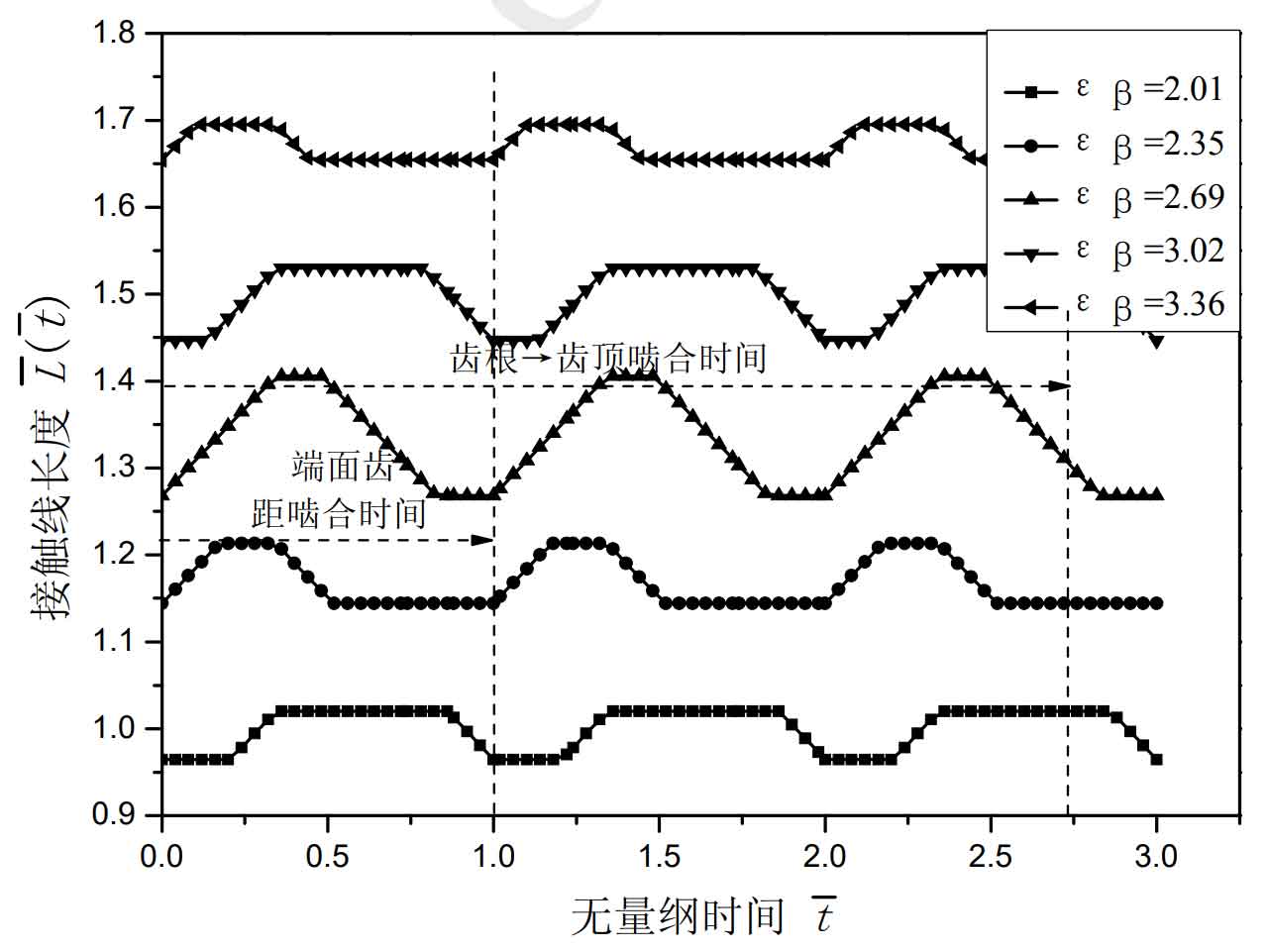

The influence curve of axial coincidence degree on contact line length calculated by this algorithm is shown in Figure 1. It can be seen from the figure that the length of helical gear transient contact line increases with the increase of axial coincidence degree.

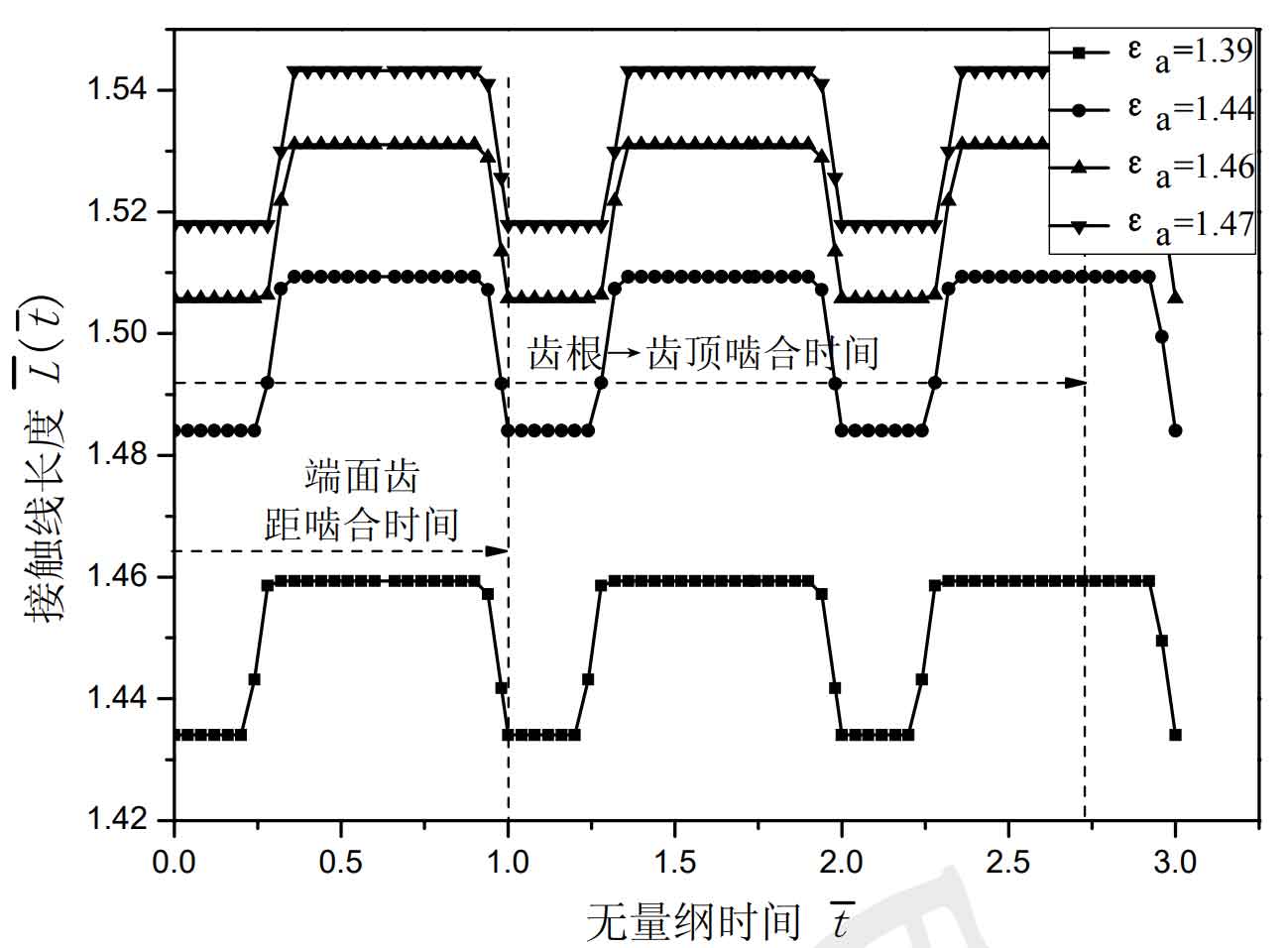

Fig. 2 is the change law curve of the influence of the end face coincidence degree on the contact line length. It can be seen from the figure that the length of the helical gear transient contact line increases with the increase of the end face coincidence degree, and the change law is basically the same.

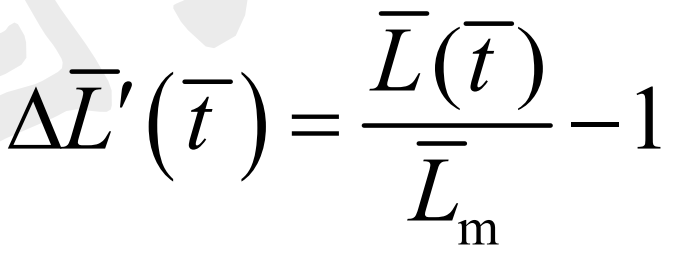

Expression formula of contact wire length change rate:

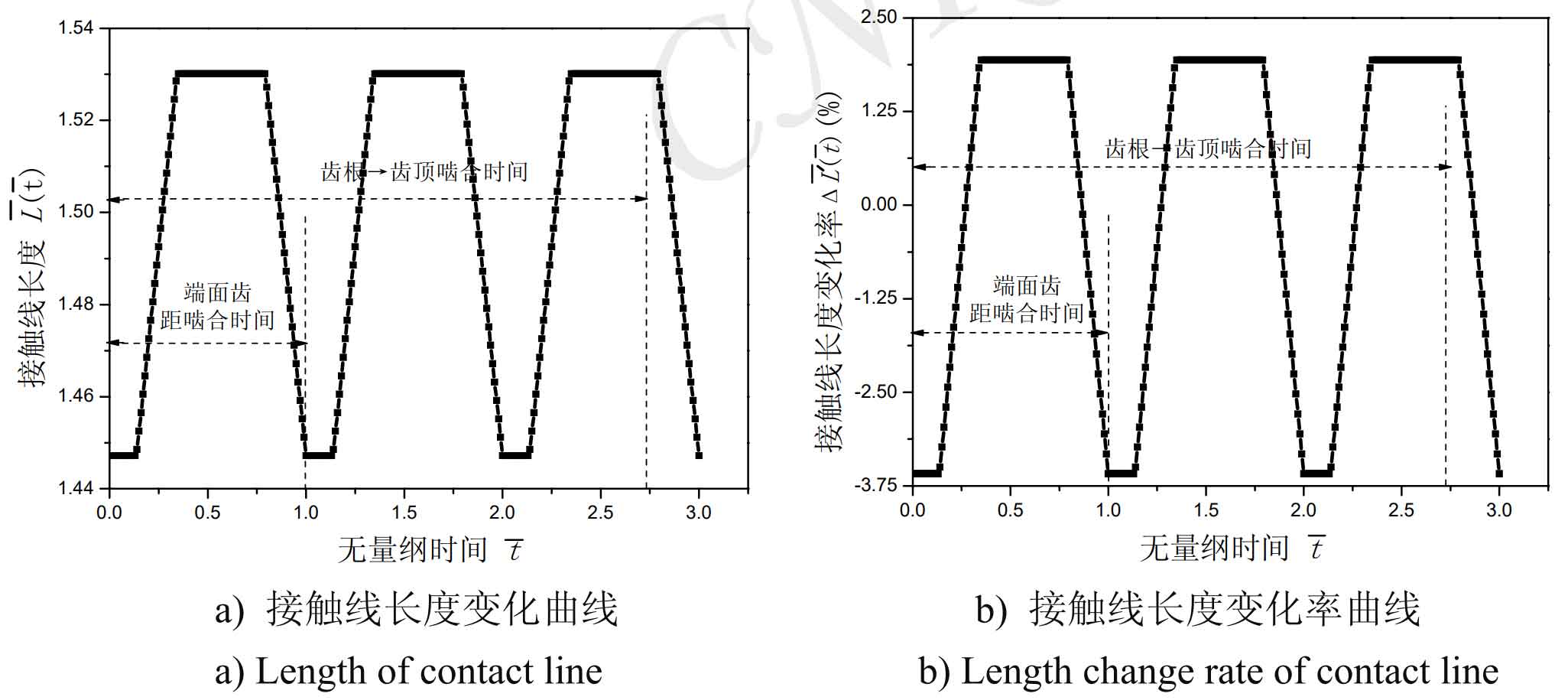

It can be seen from Figure 3 that the maximum change rate of the contact line length of the helical gear calculated by using the parameters in the table is only 6.25%. It can be seen that the change of the helical gear is relatively stable, and the resulting vibration and noise will also be reduced. Compared with the spur gear, the maximum change rate of the contact line length of the spur gear will reach 100% in the process of alternating single and double tooth meshing, thus In the alternate process of double teeth meshing, the meshing in and meshing out vibration of helical gear will be caused. The change of contact line of helical gear will also lead to the change of meshing stiffness, and then cause time-varying meshing stiffness excitation.