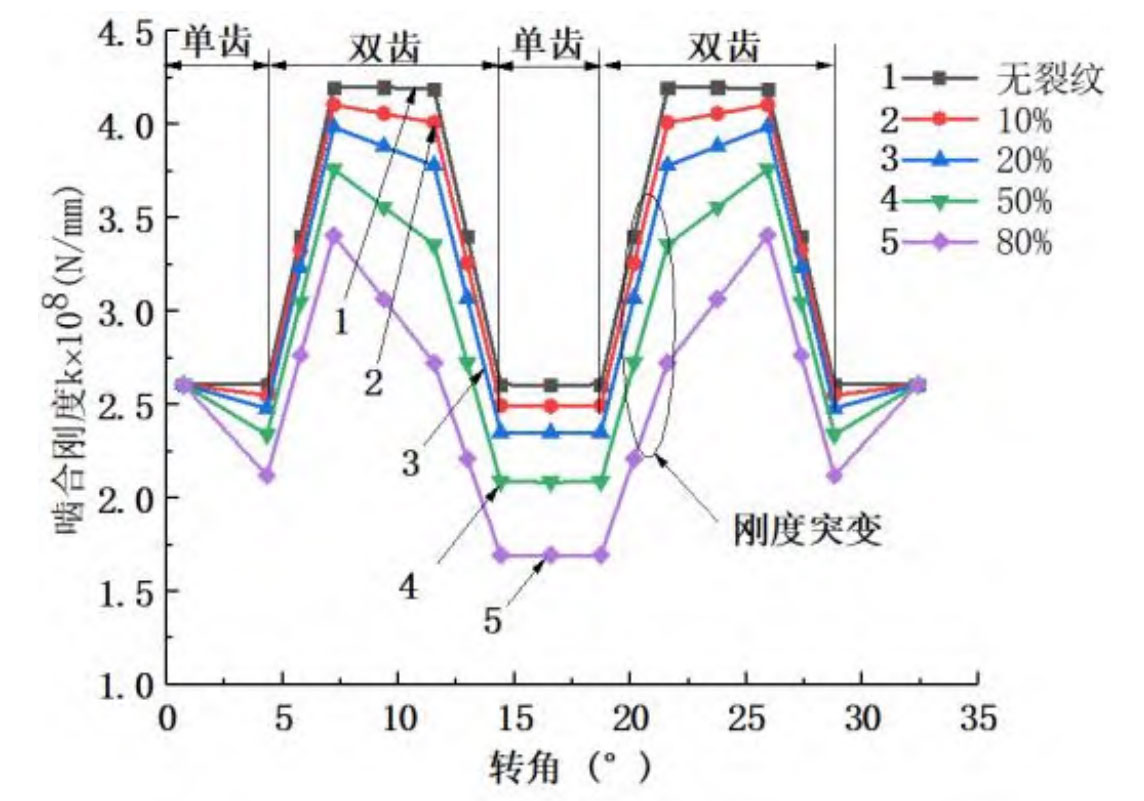

Figure 1 shows the time-varying meshing stiffness of helical gear pairs with through cracks of different depths. By calculating the parameters of the helical gear, the coincidence degree is 1.86. It can be seen from the meshing characteristics of the helical gear that the helical gear pair is a single double tooth alternating meshing. The crack free meshing stiffness in Figure 1 indicates that the single tooth meshing stiffness is small, while the double tooth meshing stiffness is large. Comply with the results of mechanical calculation analysis. The meshing stiffness also varies in cycles of high and low, with a linear mutation in stiffness between high and low changes. This is because the length of the contact line gradually increases from zero during the meshing of helical gears, and then gradually shortens from a certain position until it disengages from contact.

From Figure 1, it can be seen that the meshing stiffness decreases when cracks occur at the root of the tooth, and the maximum reduction occurs when a single tooth with cracks engages. When the crack depth is 10%, the average meshing stiffness decreases by 4.31% compared to that of non cracked helical gears; When the crack depth is 20%, the average meshing stiffness decreases by 5.72% compared to 10%; When the crack depth is 50%, the average meshing stiffness decreases by 11.25% compared to 20%; When the crack depth is 80%, the average meshing stiffness decreases by 18.83% compared to 50%. From the above data, it can be seen that as the penetrating crack expands in the depth direction, the decrease in meshing stiffness becomes more severe.

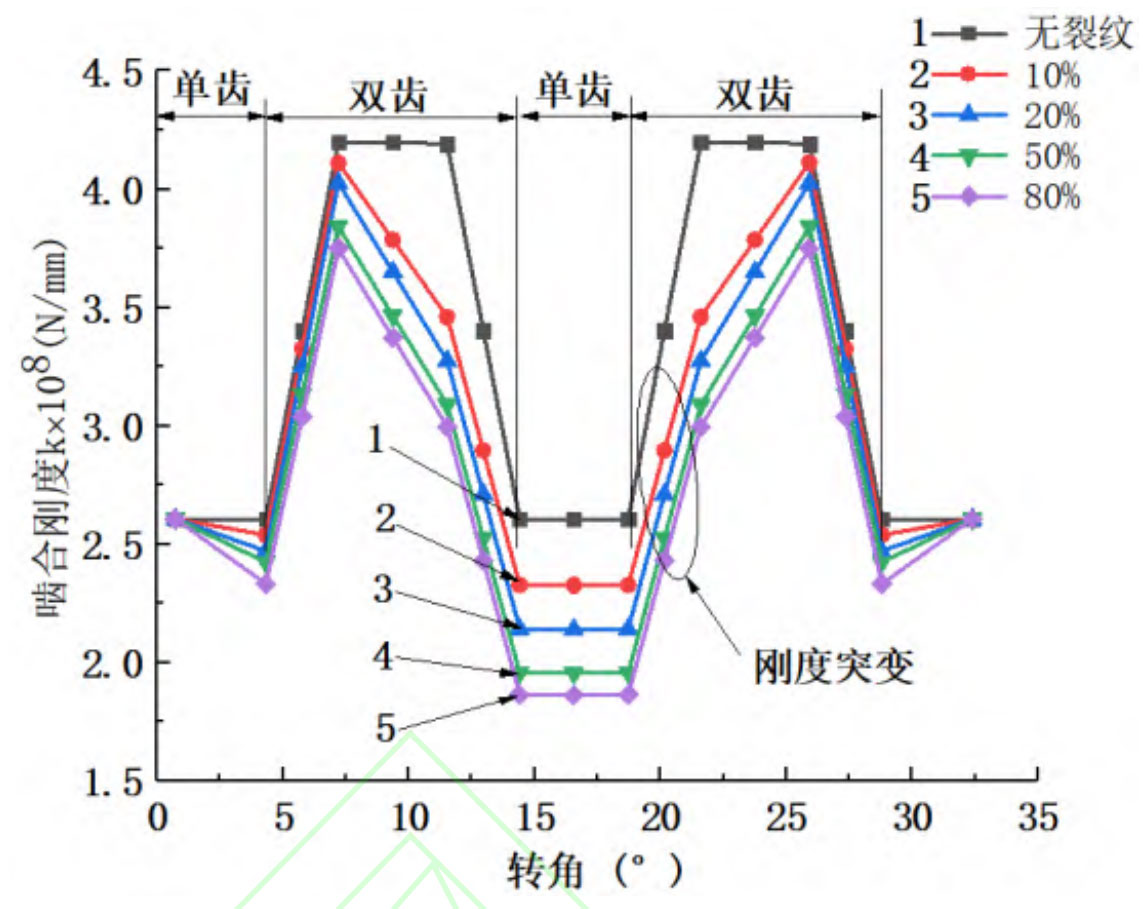

The influence of non penetrating cracks of different depths on the stiffness of helical gear pairs is shown in Figure 2. When the crack width is 100%, the time-varying meshing stiffness at depths of 10%, 20%, 50%, and 80%, respectively. From Figure 2, it can be seen that when a 10% crack is generated in the depth direction, the stiffness decreases by 10.69% compared to no crack, with the largest reduction. As the depth of the crack increases, the meshing stiffness also decreases, and the reduction amplitude gradually decreases. After calculation, cracks with widths of 25%, 50%, and 75% also follow this pattern.

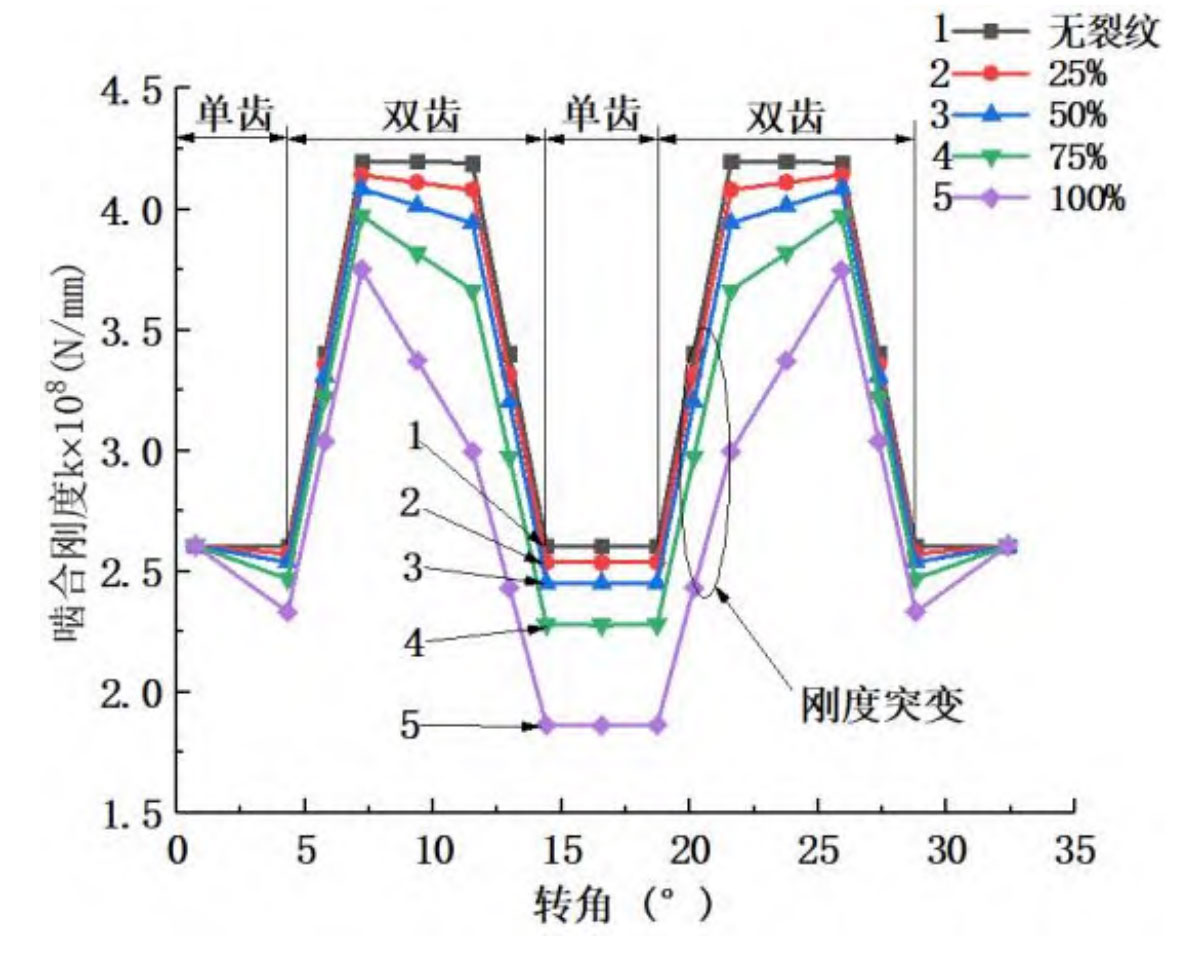

The influence of non penetrating cracks with different widths on the meshing stiffness of helical gear pairs is shown in Figure 3. The crack depth is 80%, and the width is 25%, 50%, 75%, and 100% of the time-varying meshing stiffness, respectively. According to Figure 3, when a 25% crack is generated in the width direction, the meshing stiffness decreases by 2.64% compared to when there is no crack, with the smallest reduction. As the crack propagation width increases, the meshing stiffness decreases, and the reduction amplitude significantly increases. After calculation, cracks with depths of 10%, 20%, 50%, and 80% also follow this pattern.