Assuming that the crack fault occurs on the gear teeth of the driving wheel, different types of root crack models are represented by crack depth and development angle, and the influence of root crack on comprehensive time-varying meshing stiffness of gear pair is analyzed in depth.

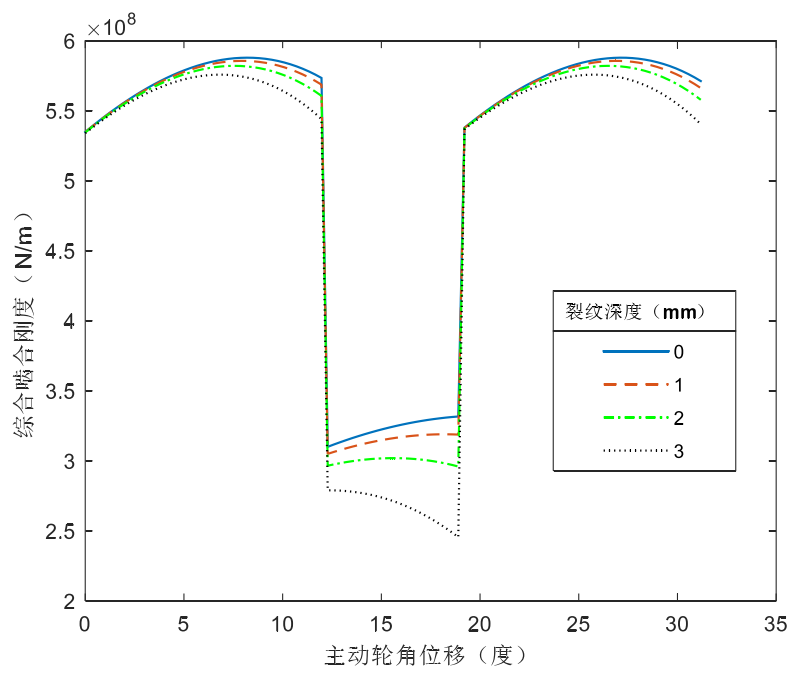

When the crack propagation angle is 45 °, the comparison curve between the comprehensive time-varying meshing stiffness of the gear pair with crack depth and that of the healthy gear pair is shown in Fig. 1: the change trend of the time-varying meshing stiffness of the gear pair with a crack root crack is the same as that of the healthy gear pair, but the value is small and decreases with the increase of the crack depth; at the beginning of meshing, the gear root has the same time-varying meshing stiffness as the healthy gear pair

The difference between the meshing stiffness of Cracked Gear Pair and that of normal gear is small, but with the gradual engagement of the gear, the load borne by the tooth becomes larger and larger, and the influence of the crack depth on the meshing stiffness increases; the load bearing of the tooth with root crack directly affects the meshing stiffness of the gear pair, resulting in the influence of the crack in the single tooth meshing zone on the time-varying meshing stiffness of the gear pair Bigger. Fig. 2 shows the influence of crack depth on the comprehensive meshing stiffness of gear pair. Compared with Fig. 1, it can be found that the influence trend of crack fault on the meshing stiffness of gear pair is consistent, which basically proves the correctness of the model.

When the crack depth is fixed at 2mm, the influence of crack development angle on the time-varying meshing stiffness of gear pair is shown in Fig. 3

The results show that: compared with normal gear pair, the value of time-varying meshing stiffness of gear pair with root crack is smaller; at the beginning of meshing, the difference of meshing stiffness of gear pair with different root cracks is small, but with the gradual engagement of gears, the load borne by teeth becomes larger and larger, and the influence of crack development angle on meshing stiffness increases, which is consistent with the results of relevant research It can also prove the correctness of the model.