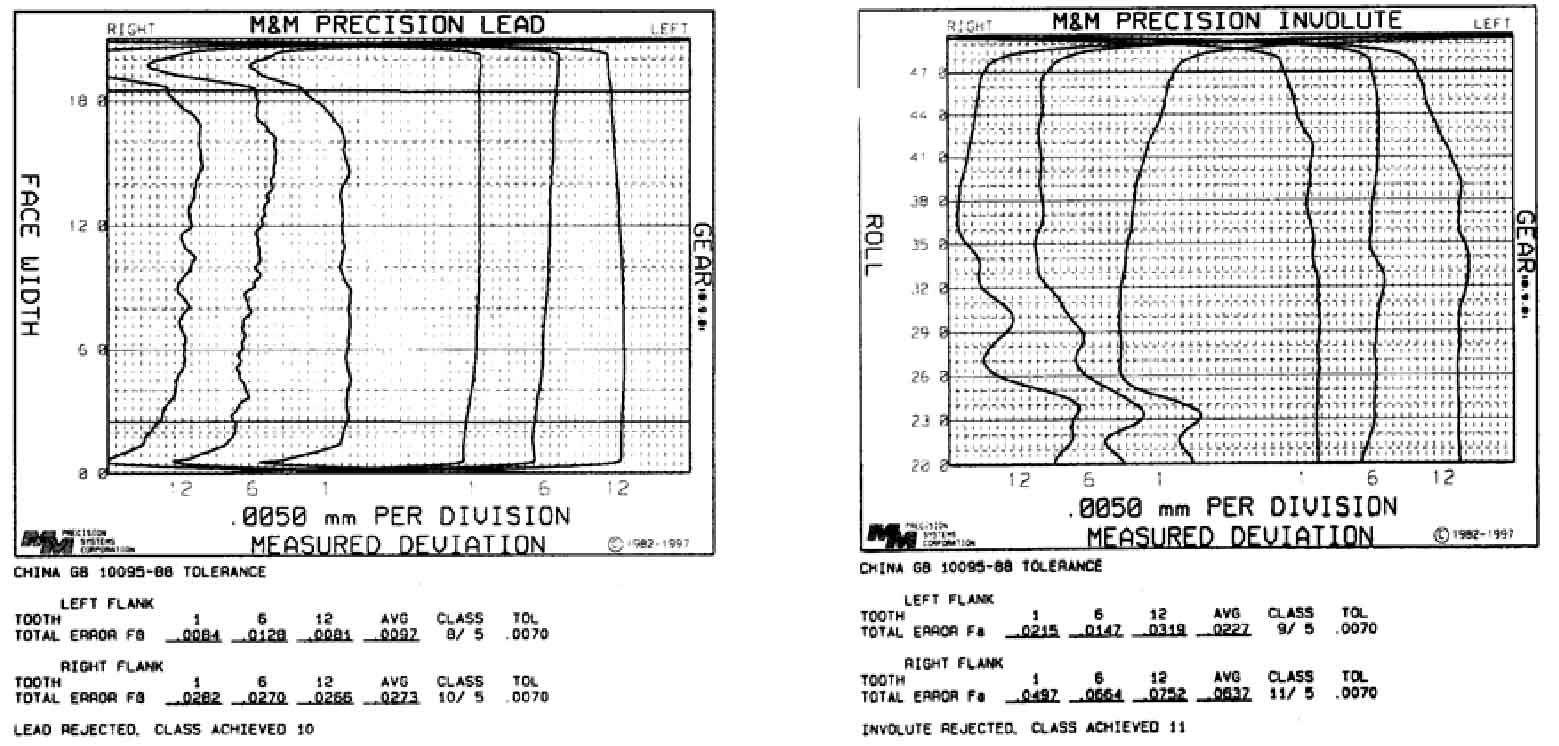

In the figure, a is the tooth direction error diagram of the pit type pinion. Compared with before the test, the error line on the left side of the tooth surface after the test is relatively flat, and the change of the tooth direction error value is small; The middle position of the error line on the right side of the tooth surface presents a wavy distribution, which shows that in the pinion meshing wear test, due to the influence of other factors, the wear in the meshing area is uneven, and the error value changes greatly after wear.

B in the figure is the tooth profile error diagram of the pit type pinion. Compared with before the test, the tooth profile error line of the right tooth surface changes significantly, and there is an obvious depression near the bottom of the curve, indicating that the meshing area of the pinion is close to the tooth top, where the wear is relatively serious and the tooth direction error value increases significantly; The tooth profile error line of the left tooth surface is relatively flat, which proves that the wear is not very serious and the error value changes little.

The concave degree of the contact surface curve of the pinion can represent the degree of meshing and wear of the pinion. Compare the variation diagram of the tooth direction error and tooth shape error of the smooth and concave pinion before and after the test. The tooth direction error and tooth shape error curve of the smooth pinion are relatively deep, indicating that the wear of the smooth pinion is relatively serious; The wear resistance of the pinion with concave bionic shape is better than that of the untreated pinion. The improvement of the wear resistance is reflected by calculating the relative error value.