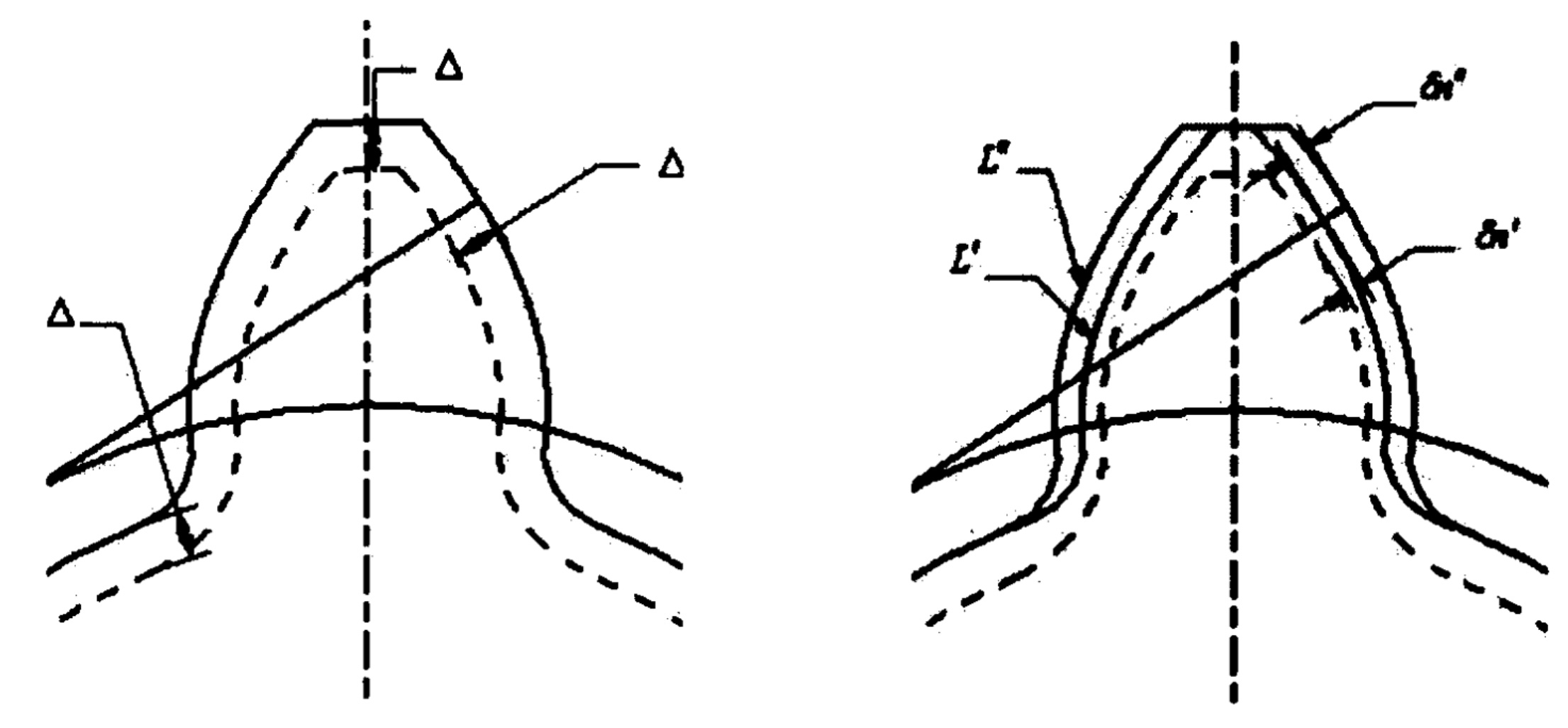

In the “one fire two forging” process for forming bevel gears, the tooth profile of hot forgings is obtained by considering the thermal expansion of forgings on the basis of the tooth profile of room temperature forgings. Therefore, the tooth profile of room temperature forgings should be designed before designing the tooth profile of hot forgings. The influence of secondary oxide scale shall be included in the design of room temperature forgings. That is, compared with the finished bevel gear, the tooth profile of the room temperature forging has one more oxide scale allowance in the normal direction of the tooth profile Δ, And the distribution of the allowance on the whole tooth profile is equal, as shown in figure (a). The dotted line in the figure is the tooth profile of the finished bevel gear, and the solid line is the tooth profile of the room temperature forging.

(b)Schematic diagram of tooth profile design for room temperature forgings

According to the characteristics of process allowance and the properties of involute tooth profile, it can be seen that the tooth profile of room temperature forging and finished bevel gear teeth

The profile has the same base circle, and the tooth profile of the room temperature forging can be obtained from the tooth profile of the finished bevel gear through comprehensive modification (radial modification plus tangential modification).

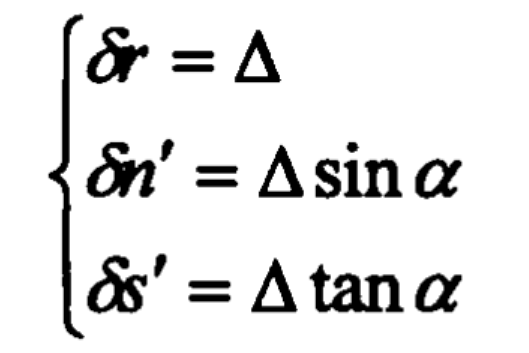

First, the finished bevel gear is subject to radial displacement, and the displacement in each direction during radial displacement is:

Where

α— Dividing circle pressure angle;

Δ— Process allowance between room temperature forgings and finished bevel gears;

δ R – radial displacement;

δ N ‘- normal displacement of unilateral tooth profile

δ S’ – half of the tooth thickness thickening on the dividing circle.

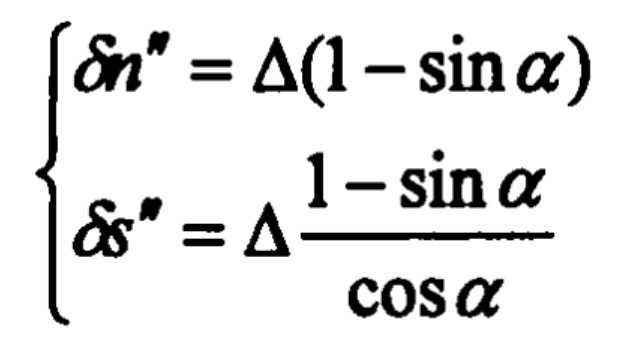

It can be seen that after the radial displacement of bevel gear, the radial displacement is greater than the normal displacement of single side tooth profile. Therefore, after the radial displacement, a tangential displacement should be carried out to make the normal displacement of single side tooth profile equal to the radial displacement. The displacement in each direction during tangential displacement is:

Where

δ N ‘- normal displacement of unilateral tooth profile;

δ S’ – tangential displacement That is, half of the tooth thickness thickening on the dividing circle.

Figure (b) shows the tooth profile of the finished bevel gear after comprehensive modification, where l ‘is the tooth profile after radial modification and l” is the tooth profile after tangential modification.

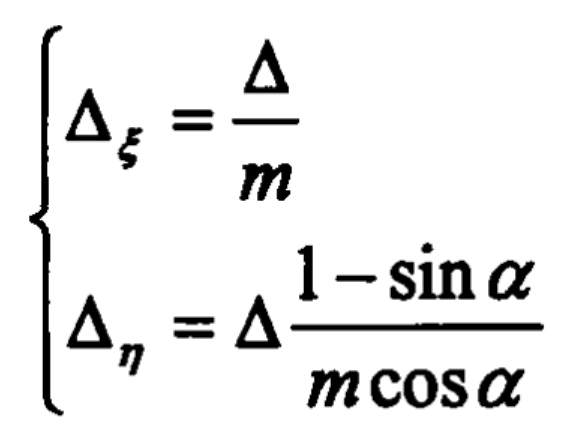

According to the modification properties of involute tooth profile, the modification coefficients of radial modification and tangential modification are respectively:

Where

M – module of finished bevel gear;

Δζ — Radial displacement coefficient;

Δη— Tangential displacement coefficient.