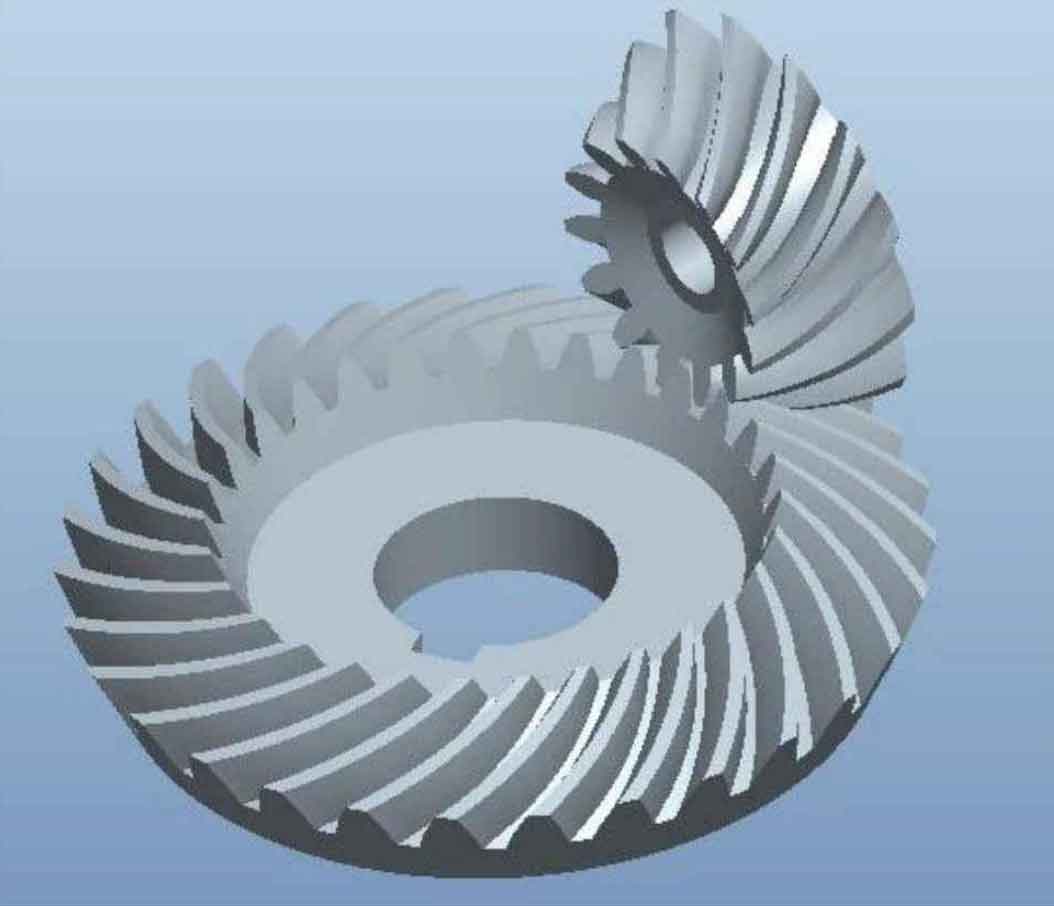

The calculated geometric parameters and machining parameters of the wheel blank lay the foundation for the tooth surface modeling. On the basis of the accurate modeling of the tooth surface, the subsequent meshing performance analysis and tooth surface design can be carried out. Firstly, the circular arc blade is used to replace the linear blade commonly used in the previous literature, and the circular arc of the tool tip is considered. A general full tooth surface model of cycloid hypoid gear, including the working tooth surface and the tooth root transition surface, is established. Then on this basis, the TCA, LTCA, etca, stress process analysis and time-varying meshing stiffness calculation of cycloid hypoid gear are carried out, and a new instantaneous contact ellipse calculation method is proposed. Finally, the main performances of two commonly used axle hypoid gear pairs are compared. The comparison results show that cycloid equal height gear has certain advantages over arc involute gear in truck bridge.

Considering the arc of the blade and the arc of the tip, a mathematical model for generating the whole tooth surface of cycloid hypoid gear is established, and the complete tooth surface including the working tooth surface and the transition surface of the tooth root is obtained. A new method for calculating the instantaneous contact ellipse in TCA is proposed, which avoids the derivation of complex principal curvature and relative curvature. On this basis, the cycloid hypoid gear teeth TCA, LTCA and etca are carried out. Based on LTCA, the tooth surface contact stress, tooth root bending stress process and the time-varying meshing stiffness of the gear pair are calculated. Finally, through the comparison of the main performance of two common axle hypoid gear pairs, It is found that cycloid and other high teeth have certain advantages in processing efficiency, labor intensity, service life and noise, which is also the reason why FAW and heavy truck are increasingly inclined to use cycloid and other high teeth in light and heavy truck axles. The meshing performance of the tooth surface is the evaluation standard of the quality of the paired tooth surface, and it is also the basis for further tooth surface optimization design and active design.