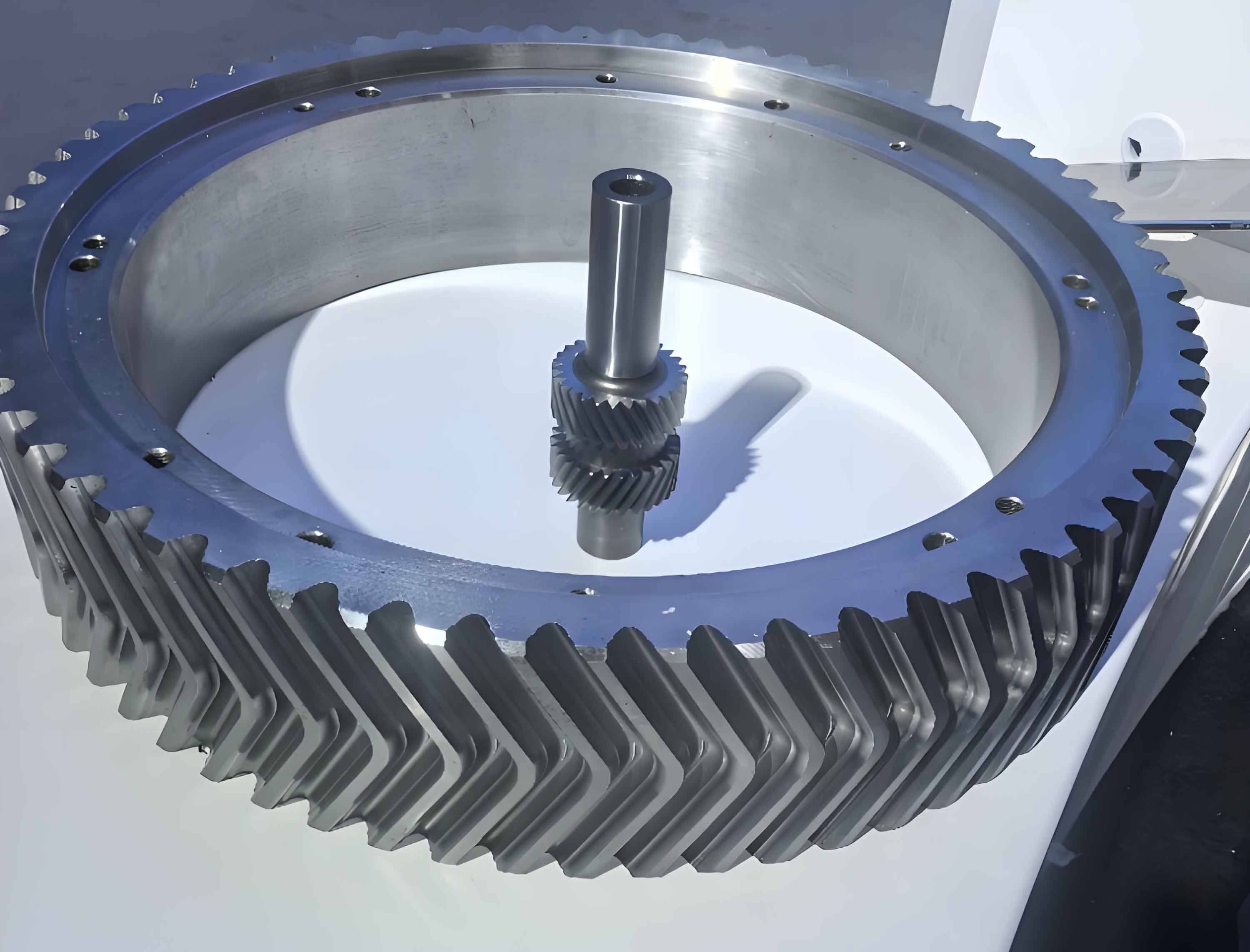

Herringbone gears are widely used in high-power transmission systems due to their axial force cancellation, compact design, and smooth operation. However, vibrations and noise caused by transmission errors and uneven contact stress distribution remain critical challenges. This study investigates topology modification methods to optimize the meshing behavior of standard herringbone gears under varying load conditions.

Mathematical Framework for Tooth Modification

The quadratic parabolic modification curve is expressed as:

$$ \Delta(x) = a x^2 + b x + c $$

where \( \Delta(x) \) represents the modification depth at position \( x \), with coefficients optimized through Monte Carlo and genetic algorithms. The optimization objective function minimizes transmission error (TE) and contact stress:

$$ \text{Minimize } F = \alpha \cdot \text{TE}_{\text{peak}} + \beta \cdot \sigma_{\text{max}} $$

where \( \alpha \) and \( \beta \) are weighting factors (0.6 and 0.4 respectively).

System Configuration and Operating Conditions

The herringbone gear pair parameters are summarized below:

| Parameter | Pinion | Gear |

|---|---|---|

| Teeth Number | 17 | 44 |

| Normal Module (mm) | 6 | 6 |

| Helix Angle (°) | 24.43 | -24.43 |

| Effective Face Width (mm) | 55 | 55 |

Five torque conditions were analyzed:

| Case | Torque (N·m) |

|---|---|

| 1 | 70 |

| 2 | 110 |

| 3 | 150 |

| 4 | 190 |

| 5 | 230 |

Performance Comparison of Modification Methods

The transmission error reduction achieved through different algorithms is quantified below:

| Load Case | Baseline TE (μm) | Monte Carlo TE (μm) | GA TE (μm) |

|---|---|---|---|

| 1 | 0.255 | 0.094 (-63.1%) | 0.078 (-69.4%) |

| 2 | 0.400 | 0.141 (-64.8%) | 0.112 (-72.0%) |

| 3 | 0.545 | 0.290 (-46.8%) | 0.239 (-56.2%) |

| 4 | 0.689 | 0.402 (-41.7%) | 0.345 (-49.9%) |

| 5 | 0.832 | 0.445 (-46.5%) | 0.421 (-49.4%) |

The contact stress reduction follows similar trends:

$$ \sigma_{\text{GA}} = 0.796\sigma_{\text{MC}} + 24.6 \quad (R^2 = 0.983) $$

where \( \sigma_{\text{GA}} \) and \( \sigma_{\text{MC}} \) represent maximum contact stresses from genetic algorithm and Monte Carlo methods respectively.

Algorithm Implementation Details

The genetic algorithm employed tournament selection with:

$$ P_{\text{crossover}} = 0.85, \quad P_{\text{mutation}} = 0.02 $$

Population size was maintained at 120 individuals across 50 generations. The Monte Carlo method utilized Latin hypercube sampling with 10,000 iterations for parameter space exploration.

Stress Distribution Analysis

The contact stress distribution shift after modification is characterized by:

$$ \text{Stress Centralization Index } \gamma = \frac{\sigma_{\text{center}}}{\sigma_{\text{edge}}} $$

| Condition | Baseline γ | Monte Carlo γ | GA γ |

|---|---|---|---|

| Full Load | 0.68 | 1.12 | 1.35 |

| Partial Load | 0.72 | 1.08 | 1.28 |

This demonstrates improved stress centralization in modified herringbone gears, particularly with genetic algorithm optimization.

Industrial Implementation Considerations

The manufacturing tolerance for effective topology modification should satisfy:

$$ \Delta_{\text{min}} \geq 3\sigma_{\text{machining}} + 2|\mu_{\text{assembly}}| $$

where \( \sigma_{\text{machining}} \) represents gear grinding precision (typically 2-3 μm) and \( \mu_{\text{assembly}} \) accounts for alignment errors.

Conclusion

Topology modification using advanced optimization algorithms significantly improves herringbone gear performance. The genetic algorithm demonstrates superior results, achieving up to 72% reduction in transmission error and 20.4% decrease in maximum contact stress compared to unmodified gears. These findings provide practical guidance for designing high-performance herringbone gear transmission systems in aerospace and heavy machinery applications.