According to the cutting principle of spiral bevel gear tooth surface, whether it is left-hand spiral bevel gear tooth surface or right-hand spiral bevel gear tooth surface, the cutting edge is pure rolling on the base cone with the (q) plane, and the cutting of spiral bevel gear tooth surface is carried out from the surface cone to the root cone, that is, the cutting edge should be cut from the surface cone to the root cone, so as to generate a complete spiral bevel gear tooth surface. In the whole tooth surface cutting process, the cutting depth of the blade is the largest when machining the big end of the spiral bevel gear, so the minimum value of the total height of the blade is the full tooth height of the big end of the spiral bevel gear, that is, the total height of the blade must be greater than the full tooth height of the spiral bevel gear.

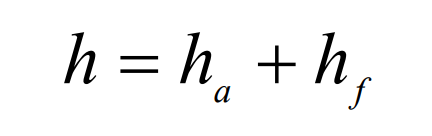

By consulting the spiral bevel gear design manual, we can know that the expression of the full tooth height h at the big end of the tapered spiral bevel gear is:

Where: Ha – tooth top height;

HF — tooth root height.

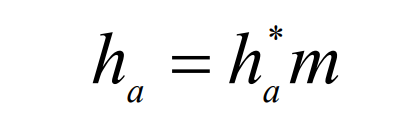

The expression of addendum height h a is:

Where: ha * – coefficient of tooth top height, generally taken as 0.85;

M — modulus.

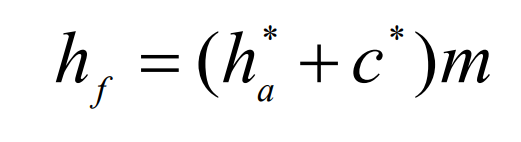

The expression of tooth root height h f is:

C * – coefficient of top clearance, generally taken as 0.188.

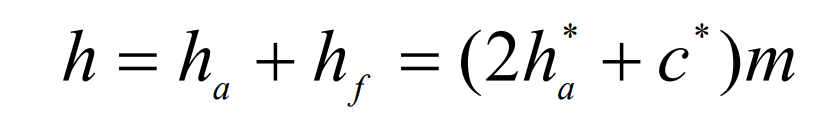

By substituting and simplifying the formula, it can be seen that the expression of large end full tooth height of spherical involute involute spiral bevel gear is as follows:

In order to cut the blade to the tooth root of spiral bevel gear, the total height h of the blade must be greater than or equal to (2ha * + C *) M. based on this, this paper designs the total height of the blade.