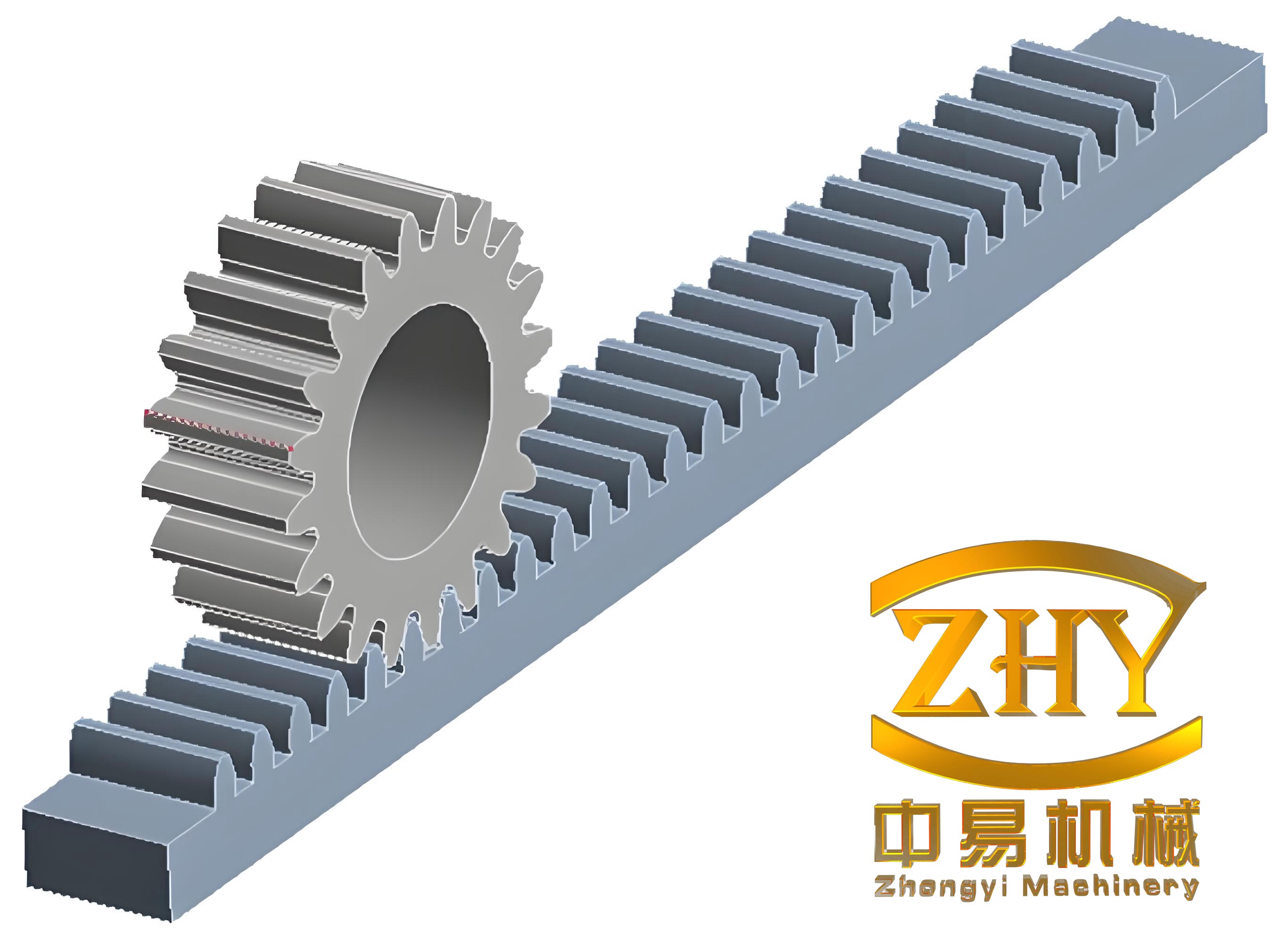

The reliable operation of heavy machinery, such as the massive ship lifts employed in major hydroelectric projects, hinges upon the performance of their core driving mechanisms. Among these, the rack and pinion gear system stands out for its ability to translate rotational motion into precise linear movement under extremely high loads. This direct-drive configuration is fundamental to applications requiring immense force transmission, such as elevating multi-thousand-ton ship chambers. The specific rack and pinion gear assemblies used in these settings are characterized by super-large modules (often exceeding 60 mm), significant face widths, and are frequently designed with profile modifications (x-shifts) to optimize load capacity and durability. However, operating under low-speed, high-torque conditions presents a formidable tribological challenge. The conjunction surfaces of the rack and pinion gear are prone to inadequate lubrication, which can precipitate severe wear, scuffing, and ultimately, premature failure of these critical, costly, and difficult-to-replace components. This work focuses on investigating the transient lubrication performance of such modified, super-large module rack and pinion gear drives, providing insights essential for their design, lubrication specification, and operational life prediction.

Understanding the lubrication regime governing the contact between mating gear teeth is paramount. The Stribeck curve classifies lubrication into three primary regimes: full-film (hydrodynamic/elastohydrodynamic), mixed, and boundary lubrication. For heavily loaded non-conformal contacts like those in a rack and pinion gear, classical hydrodynamic theory assuming rigid bodies and constant viscosity proves insufficient. The introduction of elastic deformation of the contacting surfaces and the pressure-viscosity dependence of the lubricant led to the development of Elastohydrodynamic Lubrication (EHL) theory. The transient nature of gear meshing, where load, rolling speed, sliding velocity, and contact geometry change continuously along the path of contact, necessitates a time-dependent analysis. Furthermore, the significant sliding and high pressures generate considerable frictional heating, making a thermal analysis crucial for accurate prediction of film thickness and traction. Therefore, a comprehensive Transient Thermal Elastohydrodynamic Lubrication (TEHL) model is required to realistically simulate the harsh operating conditions of a low-speed, heavy-duty rack and pinion gear.

1. Geometric and Kinematic Model of the Modified Rack and Pinion Gear

The contact between a pinion tooth and a rack tooth can be modeled as a transient line contact between two cylinders with equivalent radii of curvature that vary with the meshing position. For a standard gear pair, this equivalence is straightforward. However, profile modification (or “addendum modification”) is commonly applied to the pinion in a rack and pinion gear drive to improve specific performance characteristics. A positive modification coefficient (+x) increases the pinion tooth thickness, moving the active profile outward from the standard reference. This modification alters the effective length of the path of contact and the load distribution across the gear teeth, thereby influencing the lubrication conditions.

The fundamental geometry for a modified pinion meshing with a standard rack is considered. The equivalent radius of curvature at any point along the line of action for the pinion-to-rack contact is given by:

$$R_{eq}(t) = r_{b1} \cdot \tan(\alpha) + S(t)$$

Here, \(r_{b1}\) is the base circle radius of the pinion, \(\alpha\) is the pressure angle, and \(S(t)\) is the distance from the instantaneous contact point to the pitch point, which is a function of time \(t\) and rotational speed. The entrainment velocity \(u_e\), which is the average speed of the two surfaces drawing lubricant into the contact, and the sliding velocity \(u_s\) are critical for film formation and friction:

$$u_e(t) = \frac{u_1(t) + u_2}{2}, \quad u_s(t) = u_1(t) – u_2$$

$$u_1(t) = \omega \cdot R_{eq}(t), \quad u_2 = \omega \cdot r_{p1} \cdot \sin(\alpha)$$

where \(u_1\) is the tangential velocity of the pinion at the contact point, \(u_2\) is the constant velocity of the rack (assuming the rack is stationary and the pinion housing moves, or vice versa), \(\omega\) is the angular velocity, and \(r_{p1}\) is the pinion pitch radius. The load per unit length \(w(t)\) also varies cyclically as the contact moves from the tip of the rack (or root of the pinion) to the root of the rack (or tip of the pinion), following a typical gear loading diagram with single and double tooth contact regions.

2. Governing Equations for the Transient TEHL Model

The complete mathematical model for the line-contact TEHL problem consists of several coupled equations. We consider a non-Newtonian fluid model to account for the shear-thinning behavior of typical high-pressure lubricants under the high shear rates present in gear contacts.

2.1 Generalized Reynolds Equation

The transient form of the generalized Reynolds equation for a non-Newtonian fluid is employed:

$$\frac{\partial}{\partial x}\left( \frac{\rho^*}{\eta_e^*} h^3 \frac{\partial p}{\partial x} \right) = 12 u_e \frac{\partial (\bar{\rho} h)}{\partial x} + 12 \frac{\partial (\bar{\rho} h)}{\partial t}$$

where \(p\) is the film pressure, \(h\) is the film thickness, \(x\) is the coordinate along the rolling direction, and \(t\) is time. The terms \(\rho^*\), \(\eta_e^*\), and \(\bar{\rho}\) are effective density and viscosity parameters derived from integrals across the film thickness, accounting for the variation of fluid properties with pressure and temperature and the non-Newtonian flow. For a Ree-Eyring fluid model, the shear stress \(\tau\) is related to the shear rate \(\dot{\gamma}\) by:

$$\dot{\gamma} = \frac{\tau_0}{\eta} \sinh\left(\frac{\tau}{\tau_0}\right)$$

where \(\tau_0\) is the Eyring stress. This model accurately captures the fluid’s transition from Newtonian to shear-thinning behavior.

2.2 Film Thickness Equation

The film thickness equation includes the geometric gap, the elastic deformation of the contacting surfaces, and a central offset \(h_0\):

$$h(x,t) = h_0(t) + \frac{x^2}{2 R_{eq}(t)} – \frac{2}{\pi E’} \int_{-\infty}^{+\infty} p(x’,t) \ln|x-x’| dx’$$

Here, \(E’\) is the effective elastic modulus:

$$\frac{2}{E’} = \frac{1-\nu_1^2}{E_1} + \frac{1-\nu_2^2}{E_2}$$

where \(E_1, E_2\) and \(\nu_1, \nu_2\) are the Young’s moduli and Poisson’s ratios of the pinion and rack materials, respectively.

2.3 Lubricant Properties: Viscosity and Density

The lubricant’s viscosity dependence on pressure and temperature is modeled using the Roelands equation:

$$\eta(p,T) = \eta_0 \exp\left\{ (\ln(\eta_0) + 9.67) \left[ -1 + (1 + 5.1 \times 10^{-9}p)^{Z_0} \left( \frac{T-138}{T_0-138} \right)^{-S_0} \right] \right\}$$

The density variation is given by the Dowson-Higginson relation:

$$\rho(p,T) = \rho_0 \left[ 1 + \frac{0.6 \times 10^{-9}p}{1 + 1.7 \times 10^{-9}p} – 0.00065 (T – T_0) \right]$$

In these equations, \(\eta_0\) and \(\rho_0\) are the viscosity and density at ambient pressure and reference temperature \(T_0\), and \(Z_0\), \(S_0\) are pressure-viscosity and temperature-viscosity coefficients.

2.4 Energy Equations

The temperature field is solved using the energy equation for the fluid film, coupled with heat conduction equations for the solid bodies (pinion and rack). The fluid energy equation includes convection, conduction, viscous dissipation, and compression work:

$$\rho c \left( \frac{\partial T}{\partial t} + u \frac{\partial T}{\partial x} \right) – \frac{\partial}{\partial x}\left( \int_0^z \rho u dz’ \frac{\partial T}{\partial x} \right) – \frac{\partial}{\partial t}\left( \int_0^z \rho dz’ \frac{\partial T}{\partial t} \right) = k_f \frac{\partial^2 T}{\partial z^2} – \frac{T}{\rho} \frac{\partial \rho}{\partial T} \left( u \frac{\partial p}{\partial x} + \frac{\partial p}{\partial t} \right) + \eta \left( \frac{\partial u}{\partial z} \right)^2$$

The heat conduction in the solids is governed by:

$$\rho_s c_s u_s \frac{\partial T_s}{\partial x} = k_s \frac{\partial^2 T_s}{\partial z_s^2}$$

with continuity of heat flux at the fluid-solid interfaces.

2.5 Load Balance Equation

The integrated pressure must balance the applied external load per unit length at every instant in time:

$$w(t) = \int_{-\infty}^{+\infty} p(x,t) dx$$

3. Numerical Solution Methodology

The coupled, highly nonlinear system of equations is solved using an efficient numerical procedure. A multi-grid method is employed to accelerate the convergence of the pressure solution in the Reynolds equation. The elastic deformation integral in the film thickness equation is evaluated rapidly using the Discrete Convolution and Fast Fourier Transform (DC-FFT) technique, which dramatically reduces computational cost. The temperature fields are solved using a column-by-column sweeping method. The transient analysis marches through the meshing cycle, dividing the time along the path of contact into discrete steps. The solution from the previous time step serves as the initial guess for the next, simulating the progression of the contact through the engagement.

The key input parameters for analyzing a representative super-large module rack and pinion gear are summarized in the following tables.

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Number of Pinion Teeth | \(z_1\) | 16 | – |

| Module | \(m\) | 62.667 | mm |

| Pressure Angle | \(\alpha\) | 20 | deg |

| Profile Modification Coefficient | \(x_1\) | +0.5 | – |

| Effective Face Width | \(B\) | 600 | mm |

| Parameter | Symbol | Value | Unit |

|---|---|---|---|

| Young’s Modulus (Pinion/Rack) | \(E_1, E_2\) | 210 | GPa |

| Poisson’s Ratio | \(\nu_1, \nu_2\) | 0.28 | – |

| Density (Steel) | \(\rho_s\) | 7800 | kg/m³ |

| Thermal Conductivity (Steel) | \(k_s\) | 46 | W/(m·K) |

| Ambient Temperature | \(T_0\) | 313 | K |

| Dynamic Viscosity @ \(T_0\) | \(\eta_0\) | 0.655 | Pa·s |

| Density @ \(T_0\) | \(\rho_0\) | 1076 | kg/m³ |

| Roelands Pressure-Viscosity Index | \(Z_0\) | 0.6 | – |

| Eyring Stress | \(\tau_0\) | 5 | MPa |

4. Results and Discussion

Using the developed transient TEHL model, the lubrication performance of the super-large module rack and pinion gear is analyzed under various conditions. The primary outputs of interest are the central and minimum film thickness (\(h_c\), \(h_{min}\)), the maximum Hertzian and fluid pressure (\(p_{max}\)), the friction force or coefficient (\(\mu\)), and the temperature rise in the contact.

4.1 Lubrication State During the Start-Up Process

The start-up phase of a heavy-duty rack and pinion gear drive is critical, as the system transitions from standstill to nominal operating speed under increasing load. The film thickness is very sensitive to the entrainment velocity \(u_e\). Analysis shows that during the initial moments of start-up, the combination of low speed and high load results in a very thin lubricant film. For a gear surface with a composite roughness \(R_q\) of approximately 0.5 μm (corresponding to a high-quality ground finish), the film parameter \(\Lambda = h_{min} / R_q\) can fall below 1.5 in the initial engagement zone, indicating a mixed lubrication regime. In this regime, asperity contact is likely, increasing the risk of wear. As the speed ramps up, the entrainment velocity increases, promoting film formation. For the nominal operating condition, the minimum film thickness exceeds 0.8 μm along most of the path of contact, suggesting a transition to a full-film EHL regime, except potentially at the very tip of the rack tooth where sliding is highest and the geometry is less favorable.

The transient pressure and film thickness profiles at a specific meshing position (e.g., near the pitch point) during start-up exhibit classic EHL features: a sharp pressure spike near the outlet and a characteristic constriction in the film thickness at the same location. The maximum fluid pressure closely follows the trend of the applied Hertzian load but is moderated by the lubricant’s entrainment.

4.2 Influence of Gear Design Parameters on Lubrication

The design parameters of the rack and pinion gear have a profound impact on its tribological performance.

Profile Modification Coefficient (x): Increasing the positive modification on the pinion shifts the active profile outward. This action increases the equivalent radius of curvature \(R_{eq}\) at the initial engagement point (rack tooth tip). A larger \(R_{eq}\) reduces the contact pressure (Hertzian stress) and slightly increases the entrainment velocity, both of which contribute to a thicker lubricant film. Consequently, the risk of severe wear at the vulnerable rack tip during the high-sliding engagement is mitigated. The friction force in the engagement zone is also reduced.

Module (m): Increasing the module, while keeping the center distance and ratio constant for a rack and pinion gear, generally leads to stronger teeth. From a lubrication perspective, a larger module increases the equivalent radius of curvature proportionally across the entire path of contact. This significantly reduces the contact pressure and increases the film thickness. The variation in friction across the meshing cycle becomes smoother, reducing dynamic excitations. The following table summarizes the trend for increasing key parameters from a baseline design.

| Parameter Increased | Effect on Contact Pressure | Effect on Film Thickness | Effect on Friction | Overall Lubrication Impact |

|---|---|---|---|---|

| Profile Modification (x) | Decreases | Increases | Decreases (at engagement) | Positive |

| Module (m) | Significantly Decreases | Significantly Increases | Reduces variation | Very Positive |

| Pressure Angle (\(\alpha\)) | Decreases | Increases | Decreases | Positive |

Pressure Angle (\(\alpha\)): A larger pressure angle (e.g., 22.5° or 25° instead of 20°) increases the base circle radius and the equivalent radius of curvature. This reduces the contact stress. Although the sliding velocity may increase slightly, the net effect of reduced pressure and increased \(R_{eq}\) is an improvement in the predicted central film thickness and a reduction in the friction coefficient, particularly in the single-pair contact region.

4.3 Influence of Material and Lubricant Properties

Surface Coatings and Hardness: Hard coatings like TiN or Al₂O₃ are often applied to gear surfaces to enhance wear resistance. While excellent for preventing abrasion and adhesion, their high elastic modulus (e.g., 300-400 GPa) affects EHL performance. The analysis shows that for a given load and geometry, a harder material (higher \(E’\)) results in a smaller contact area, leading to higher contact pressures. The film thickness, which depends on \(R_{eq}\) and material properties via the dimensionless parameters, is slightly reduced for harder materials. More significantly, the higher pressure and potentially different thermal properties can lead to increased friction and flash temperatures. There is a trade-off: a harder surface resists wear but may operate under slightly less favorable EHL conditions with higher traction. Softer, through-hardened steels or case-hardened surfaces with a tough core can offer a better balance for the rack and pinion gear under mixed lubrication conditions during start-up.

Lubricant Viscosity: The base oil viscosity \(\eta_0\) is a dominant factor in film formation, especially in the low-speed regime. The film thickness in an EHL contact is approximately proportional to \((\eta_0 \cdot u_e)^{0.7}\). Therefore, selecting a lubricant with a sufficiently high viscosity grade is critical for a low-speed, heavy-duty rack and pinion gear to establish a protective film. Increasing viscosity directly and markedly increases the predicted central and minimum film thickness, helping to ensure \(\Lambda > 2\) for full-film lubrication. However, excessively high viscosity can lead to increased churning losses and difficulties in lubricant supply. The choice must balance film formation with operational efficiency.

4.4 Friction and Thermal Effects

The friction force in the rack and pinion gear contact arises from shearing the lubricant film. The non-Newtonian model is essential here. The friction coefficient is not constant; it varies along the path of contact, peaking in regions of high sliding, such as near the tip and root of the rack tooth. The thermal analysis reveals that significant temperature rises (local flash temperatures) can occur in these high-sliding zones, sometimes exceeding 30-50 K above the bulk temperature. This heating causes a local reduction in lubricant viscosity, which in turn thins the film slightly—an effect captured by the TEHL model but missed by an isothermal analysis. This thermal thinning effect reinforces the importance of selecting a lubricant with good viscosity-index improvers and high-pressure properties.

5. Conclusion

This analysis of the transient thermal elastohydrodynamic lubrication in a super-large module modified rack and pinion gear drive provides crucial insights for engineering such critical heavy-duty systems. The primary conclusions are:

1. The start-up phase presents the greatest lubrication challenge for the rack and pinion gear. Low entrainment speeds combined with high loads can force the contact into a mixed lubrication regime, particularly at the engaging tip of the rack tooth, making this zone most susceptible to initial wear. Ensuring proper lubricant availability and properties during start-up is essential.

2. Gear design parameters can be optimized to improve inherent lubrication performance. Increasing the profile modification coefficient, module, or pressure angle generally leads to reduced contact pressure, increased film thickness, and smoother friction transitions, thereby enhancing the rack and pinion gear‘s resistance to wear and scuffing.

3. Material selection involves a tribological trade-off. While ultra-hard coatings offer excellent wear resistance, they can elevate contact pressures and friction. A balanced approach using case-hardened steels with a favorable core toughness often provides an optimal solution for the demanding cyclic loads seen in a rack and pinion gear.

4. Lubricant specification is paramount. A high-viscosity lubricant with strong pressure-viscosity response and shear stability is necessary to generate an adequate EHL film under low-speed, high-pressure conditions. The thermal thinning effect underscores the need for lubricants that maintain performance under localized heating.

In summary, the successful operation and longevity of massive rack and pinion gear drives, like those in ship lifts, depend on a holistic design strategy that integrates mechanical design, material science, and tribology. The transient TEHL model serves as a powerful tool to evaluate design choices and lubrication strategies, helping to prevent premature failure and ensure reliable service over decades of operation.