Abstract

Transmission gears are the critical components in electric drive axle reducers, which significantly impact the performance, lifetime, and comfort of the entire system. This paper presents a comprehensive approach to optimize the transmission gear parameters for electric drive axle reducers. By integrating the S-N curve assumption method with Romax software, this study aims to improve gear strength, reduce transmission errors, and minimize noise generation. The proposed methodology encompasses macro-parameter optimization and micro-geometry modifications to achieve a superior gearing system. The optimized design is verified through noise testing, demonstrating a notable improvement in various performance metrics.

Keywords: Transmission gear, electric drive axle reducer, macro-parameter optimization, micro-geometry modification, noise reduction.

1. Introduction

Electric vehicles (EVs) have gained significant traction in recent years due to their environmental friendliness and low noise levels. However, despite the inherent benefits of EVs, the electric drive axle reducer—a vital component in transmitting power from the electric motor to the drive wheels—must still meet stringent requirements in terms of efficiency, durability, and noise emission.

Transmission gears within the electric drive axle reducer play a crucial role in power transmission, and their design parameters significantly impact the overall performance of the system. Inadequate gear design can lead to premature failure, excessive noise, and increased maintenance costs. Therefore, optimizing transmission gear parameters is essential to enhancing the performance of electric drive axle reducers.

This paper proposes a systematic approach to optimizing transmission gear parameters using Romax software. The methodology incorporates macro-parameter adjustments and micro-geometry modifications to achieve improved strength, reduced transmission errors, and minimized noise levels. The optimized design is verified through noise testing, and the results demonstrate significant improvements across various performance metrics.

2. Literature Review

Transmission gear design has been a topic of extensive research over the years. Traditional gear design methods often rely on empirical rules and trial-and-error approaches, leading to design inefficiencies and suboptimal performance. With the advancement of computational tools, such as finite element analysis (FEA) and multi-body dynamics simulations, more sophisticated design methodologies have emerged.

Several studies have focused on optimizing transmission gear parameters to improve performance. For instance, Liu et al. [1] proposed a multi-objective optimization framework for helical gear pairs, considering factors such as transmission error, contact stress, and bending stress. Similarly, Velex and Maatar [2] investigated the influence of tooth profile modifications on the dynamic behavior of spur and helical gears.

While these studies provide valuable insights, there is still a lack of comprehensive methodologies that integrate macro-parameter adjustments and micro-geometry modifications for electric drive axle reducer gears. The current study aims to bridge this gap by proposing a systematic optimization approach using Romax software.

3. Methodology

The proposed methodology involves two primary steps: macro-parameter optimization and micro-geometry modifications. This section details each step and the tools used to implement them.

3.1 Macro-Parameter Optimization

Macro-parameter optimization involves adjusting gear design parameters at a broader level to improve overall performance. These parameters include tooth count, module, pressure angle, helix angle, and center distance. The optimization process utilizes Romax software, which provides a powerful platform for analyzing and optimizing gear designs.

3.1.1 Romax Software Overview

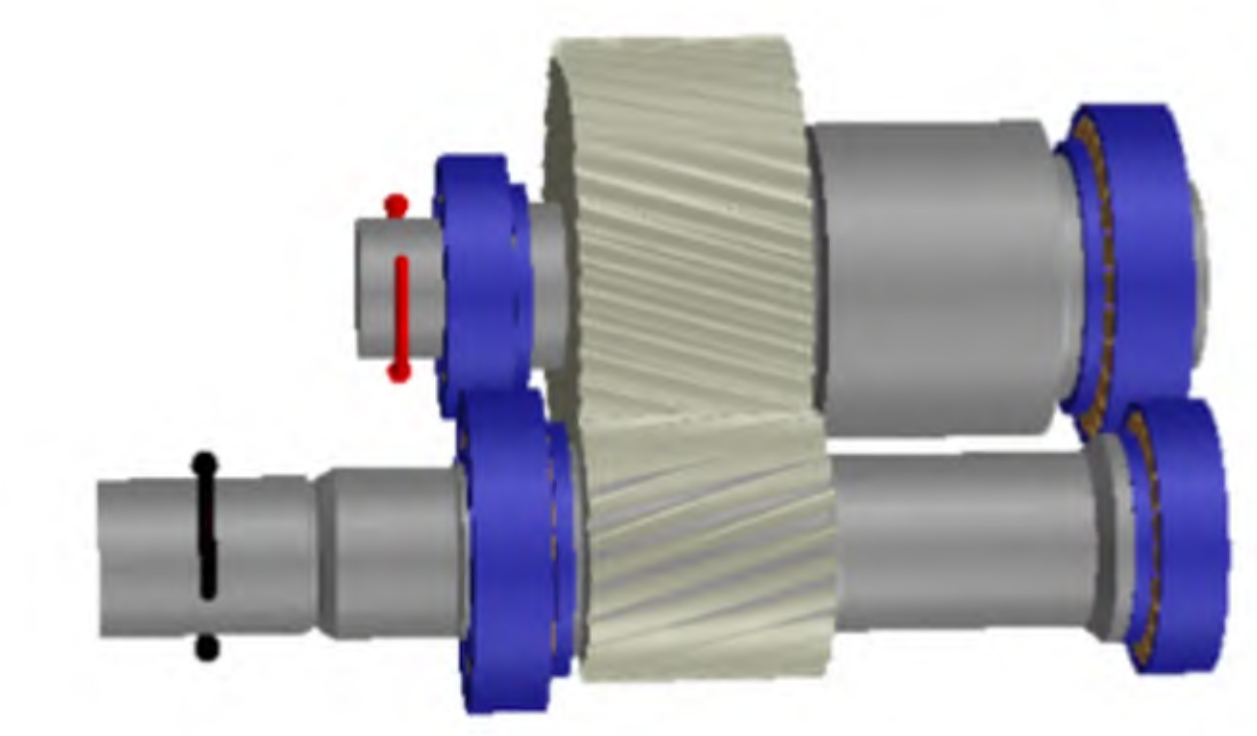

Romax Designer is a comprehensive software suite for the design, analysis, and optimization of mechanical transmission systems. It integrates various tools for simulating gear meshing, bearing analysis, and system-level dynamics. For this study, the gear design and analysis capabilities of Romax were leveraged to optimize transmission gear parameters.

3.1.2 Optimization Process

The macro-parameter optimization process involves the following steps:

- Initial Gear Design: Establish an initial gear design based on standard gear parameters and material properties.

- Load Spectrum Conversion: Convert the actual road spectrum into an equivalent load spectrum using the S-N curve assumption method. This step ensures that the simulated loads represent the actual operating conditions accurately.

- Romax Simulation: Import the initial gear design into Romax and simulate the gear meshing under the equivalent load spectrum. Analyze the results, including bending fatigue strength, contact stress, transmission errors, and重合度.

- Factorial Design of Experiments (DOE): Utilize the full factorial design of experiments (DOE) module in Romax to systematically vary macro-parameters such as tooth count, module, pressure angle, helix angle, and center distance.

- Optimization Analysis: Analyze the DOE results to identify optimal macro-parameter combinations that maximize strength, minimize transmission errors, and improve overall performance.

- Validation: Verify the optimized design through additional Romax simulations to ensure that the desired performance improvements are achieved.

3.2 Micro-Geometry Modifications

After macro-parameter optimization, micro-geometry modifications are applied to further enhance gear performance. Micro-geometry modifications involve adjusting tooth profiles and lead crowning to optimize load distribution, reduce transmission errors, and minimize noise generation.

3.2.1 Gear Micro-Geometry Concepts

Micro-geometry modifications can significantly impact gear performance. Key modifications include:

- Tooth Profile Modifications: Adjustments to the tooth profiles, such as involute modifications, can optimize contact patterns and reduce stress concentrations.

- Lead Crowning: Lead crowning involves modifying the tooth flanks to create a slight convex profile along the tooth width. This modification helps distribute load more evenly and reduce transmission errors.

- End Relief: End relief modifications can minimize edge contact and reduce noise generation during gear meshing.

3.2.2 Micro-Geometry Optimization Process

The micro-geometry optimization process involves the following steps:

- Initial Micro-Geometry Design: Establish an initial micro-geometry design based on standard profiles and modifications.

- Romax Simulation with Micro-Modifications: Import the initial micro-geometry design into Romax and simulate gear meshing under the equivalent load spectrum. Analyze the contact patterns, load distribution, and transmission errors.

- Iterative Modification and Simulation: Based on the initial simulation results, iteratively adjust the micro-geometry parameters, such as lead crowning and end relief, and re-simulate the gear meshing.

- Optimization Analysis: Analyze the simulation results to identify optimal micro-geometry modifications that improve load distribution, reduce transmission errors, and minimize noise generation.

- Validation: Verify the optimized micro-geometry design through additional Romax simulations and, if possible, experimental testing.

4. Case Study: Electric Drive Axle Reducer Gear Optimization

This section presents a case study demonstrating the proposed optimization methodology for an electric drive axle reducer gear set.

4.1 Initial Gear Design

The initial gear design parameters are shown in Table 1. The gears are made of surface-quenched steel (MQ grade) with standard material properties as listed in Table 2.

Table 1: Initial Gear Design Parameters

| Parameter | Drive Gear | Driven Gear |

|---|---|---|

| Tooth Count | 22 | 47 |

| Module | 1.75 mm | 1.75 mm |

| Pressure Angle | 20° | 20° |

| Helix Angle | 17° | 17° |

| Center Distance | 63 mm | – |

| Material | MQ Steel | MQ Steel |

| Quality (ISO Grade) | 6 | 6 |

Table 2: Material Properties of MQ Steel

| Property | Value |

|---|---|

| Surface Hardness (HV) | 670 |

| Core Hardness (HRC) | 31 |

| Elastic Modulus (MPa) | 2.07e5 |

| Yield Strength (MPa) | 314 |

| Ultimate Tensile Strength (MPa) | 2180 |

| Density (kg/m³) | 7800 |

| Poisson’s Ratio | 0.3 |

| Thermal Expansion (μm/mK) | 12 |

| Specific Heat (J/kg·K) | 490 |

| Allowable Contact Stress (MPa) | 1500 |

| Allowable Bending Stress (MPa) | 500 |

4.2 Macro-Parameter Optimization

The macro-parameter optimization process was performed using the full factorial DOE module in Romax. Key macro-parameters were varied within practical ranges, as shown in Table 3.

Table 3: Range of Macro-Parameters for DOE

| Parameter | Min Value | Max Value |

|---|---|---|

| Tooth Count (Drive) | 20 | 30 |

| Tooth Count (Driven) | 45 | 55 |

| Module | 1.5 mm | 2.0 mm |

| Pressure Angle | 18° | 22° |

| Helix Angle | 15° | 25° |

The DOE results were analyzed to identify the optimal macro-parameter combinations. The optimized macro-parameters are shown in Table 4, along with the key performance metrics before and after optimization.

Table 4: Comparison of Performance Metrics Before and After Macro-Parameter Optimization

| Metric | Before Optimization | After Optimization |

|---|---|---|

| Bending Fatigue Safety Factor | 1.53 (Drive), 1.38 (Driven) | 1.92 (Drive), 1.58 (Driven) |

| Contact Fatigue Safety Factor | 1.07 (Drive), 1.13 (Driven) | 1.11 (Drive), 1.18 (Driven) |

| Flash Temperature Glue Factor | 1.22 | 1.73 |

| Average Temperature Glue Factor | 1.37 | 1.69 |

| Transmission Error (μm) | 0.93162 | 0.53729 |

| Contact Ratio | 3.73 | 4.89 |

4.3 Micro-Geometry Modifications

Based on the optimized macro-parameters, micro-geometry modifications were applied to further improve gear performance. Key modifications included lead crowning and end relief.

The micro-geometry parameters were iteratively adjusted and simulated in Romax to identify the optimal configurations. The final micro-geometry modifications and their corresponding performance improvements are summarized in Table 5.

Table 5: Micro-Geometry Modifications and Performance Improvements

| Modification | Value (μm) | Performance Improvement |

|---|---|---|

| Lead Crowning | 8.31 | Improved load distribution, reduced transmission errors |

| End Relief | As required | Minimized edge contact, reduced noise |

| Transmission Error (μm) | 0.53729 | Reduced to 0.21883 (59.2% reduction) |

5. Experimental Validation

To validate the optimized gear design, experimental testing was conducted on a prototype electric drive axle reducer. Noise measurements were performed under simulated driving conditions, and the results were compared with those obtained from the initial design.

The experimental results, demonstrate a significant reduction in noise levels across various frequency bands. The optimized design effectively shifted noise peaks and reduced the overall noise intensity.

6. Conclusion

This paper presents a comprehensive approach to optimizing transmission gear parameters for electric drive axle reducers. By integrating macro-parameter adjustments and micro-geometry modifications, the proposed methodology achieves significant improvements in gear strength, transmission errors, and noise levels. The optimized design was validated through experimental testing, demonstrating a notable reduction in noise across various frequency bands.

The key findings of this study are summarized below:

- Macro-Parameter Optimization: Adjusting tooth count, module, pressure angle, helix angle, and center distance can significantly enhance gear strength and reduce transmission errors.

- Micro-Geometry Modifications: Lead crowning and end relief effectively distribute load more evenly, minimize edge contact, and reduce noise generation.

- Experimental Validation: Experimental testing confirmed the improvements observed in simulations, demonstrating the effectiveness of the proposed optimization methodology.

The proposed optimization methodology provides a practical approach for designing high-performance transmission gears for electric drive axle reducers. Future work could explore additional micro-geometry modifications and investigate the impact of manufacturing tolerances on optimized gear performance.