The undercutting inspection of the large and small wheels of the aligned hyperboloid gear is mainly to calculate whether the height displacement coefficient of the designed gear pair small wheel calculation point is greater than the minimum value here. The inspection method is as follows:

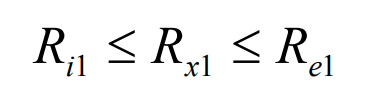

Select the cone distance rx1 of the inspection point of the hypoid gear pinion, and the determination method of rx1 is as follows:

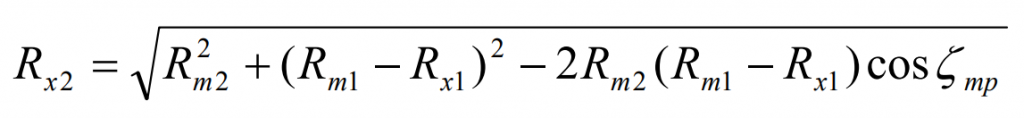

For the large wheel cone distance rx2 at the boundary point of the hypoid gear pinion (its value may be smaller than ri2 and larger than re2), the determination method of rx2 is as follows:

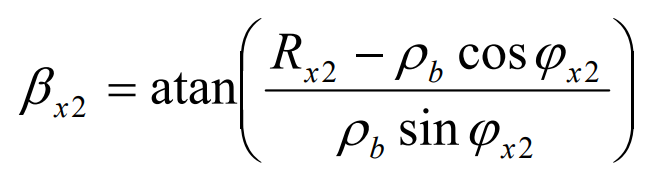

When the continuous hobbing method is adopted, the helix angle of the inspection point of the large wheel of hypoid gear β X2 is determined by the following formula:

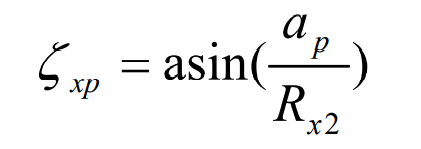

Offset angle of hypoid gear pinion on the pitch plane of inspection point ζ XP is determined by the following formula:

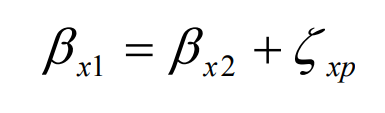

Helix angle of inspection point of hypoid gear pinion β X1 is:

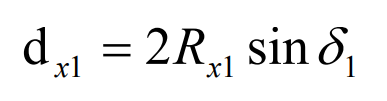

The pitch diameter dx1 of the inspection point of hypoid gear pinion is:

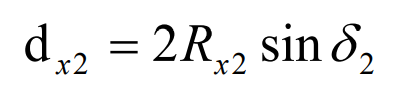

The pitch diameter DX2 of the inspection point of the large hypoid gear is:

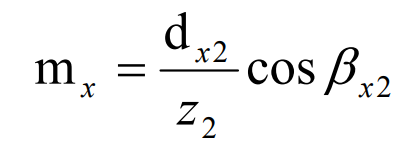

The normal modulus MX of the inspection point is:

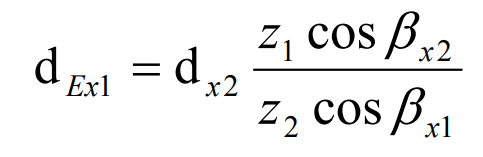

The effective diameter dex1 of the inspection point of hypoid gear pinion is:

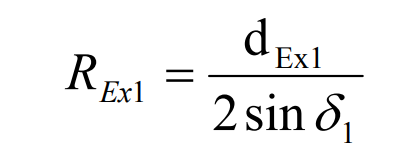

The appropriate cone distance rex1 is:

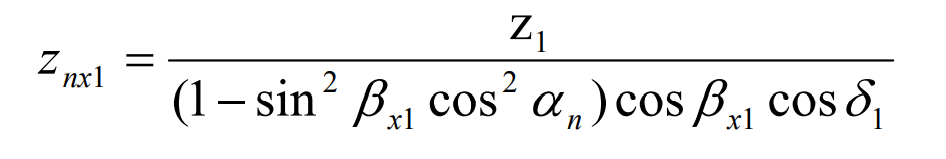

The median value znx1 is:

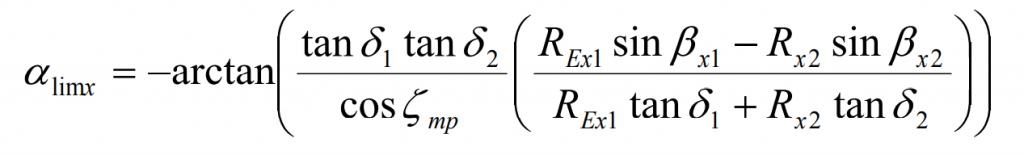

Ultimate pressure angle of inspection point α Limx is:

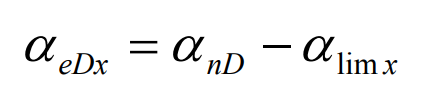

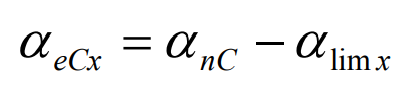

Effective pressure angle on the working side of the inspection point α EDX is:

Effective pressure angle on the non working side of the inspection point α ECX is:

The smaller effective pressure angle is further selected through the calculation of the following formula:

When α eDx< α ECX, at this time α eminx= α ECX, when α eDx≤ α When ECX, there is α eminx= α eDx。 At this time, a smaller effective pressure angle can be determined.

Determine the minimum height modification coefficient of the calculation point of the hypoid gear pinion: xhminx1

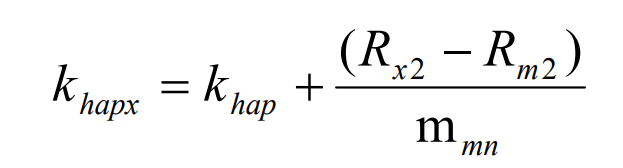

The working tooth top height khapx of the inspection point is:

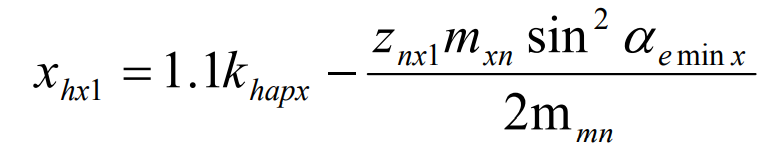

The minimum height modification coefficient xhx1 of the inspection point of hypoid gear pinion is:

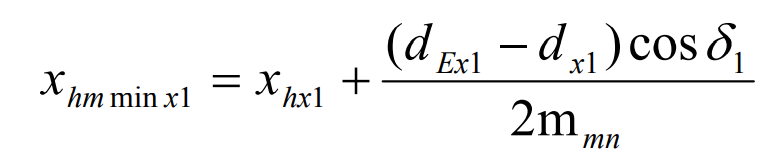

The minimum height modification coefficient xhmminx1 of the calculation point of hypoid gear pinion is:

According to the above calculation results, if xhm1 > xhmminx1, the undercutting of hypoid gear pinion can be avoided.

In order to check whether undercutting occurs to the designed small wheel, rx1 = 130 is taken according to the above formula. In the calculation example, the tooth top height coefficient and tooth height coefficient of hypoid gear small wheel are taken as 0.05 and 3.5 respectively. After calculation, xhm1 = 1.53 and xhmminx1 = 0.83, that is, xhm1 > xhmminx1, so the above conditions without undercutting are met, That is, the designed small wheel of hypoid gear with small number of teeth and large reduction ratio will not undercut during machining.