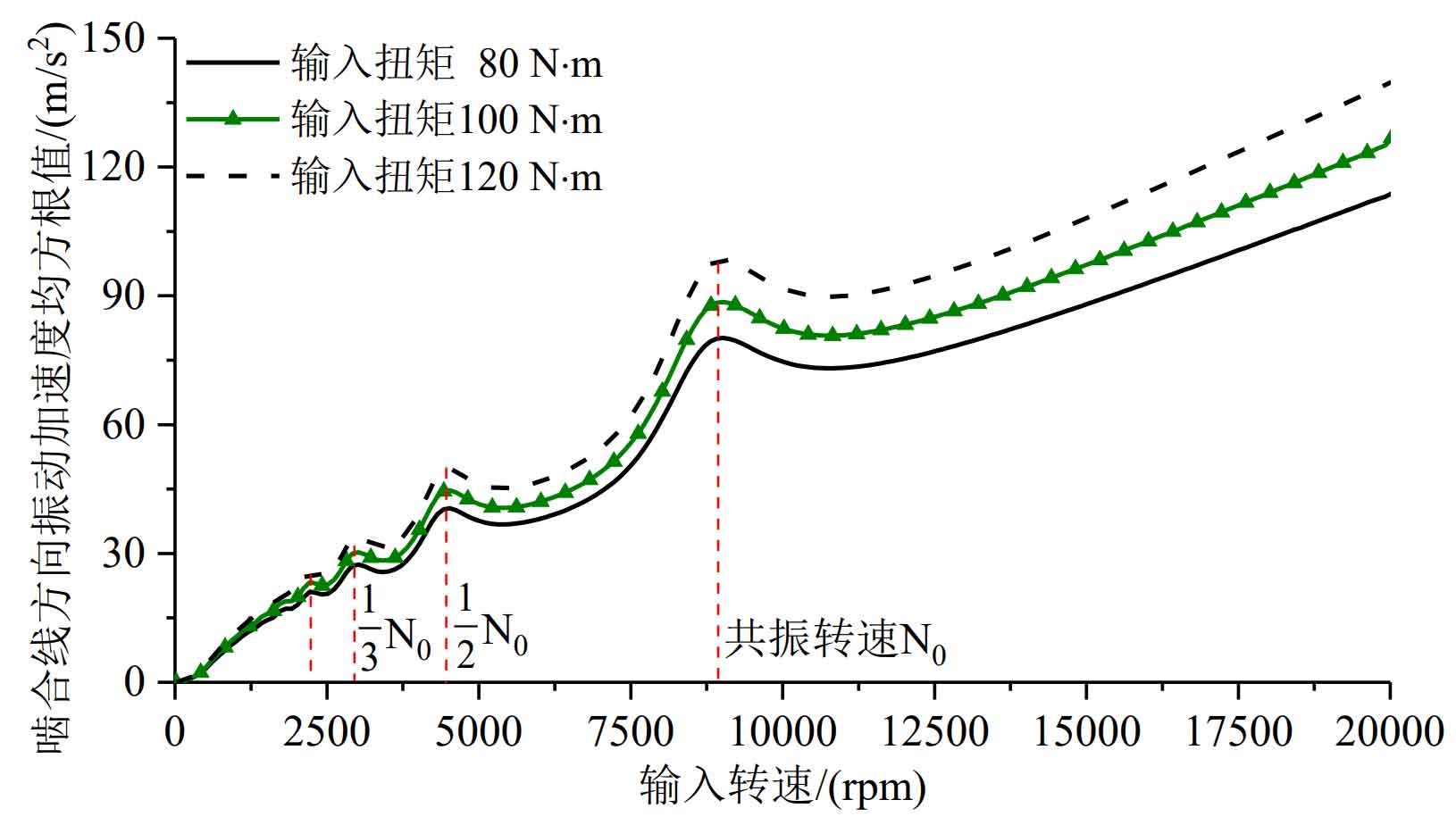

In order to study the vibration characteristics of the system under separate excitation of meshing impact, the meshing impact curve obtained is input into the dynamic equations of single-stage helical gear transmission, and the vibration response of single-stage helical gear transmission system under three working conditions of input torque of 80N · m, 100N · m, 120N · m is obtained, and the vibration speed diagram shown in Figure 1 is drawn.

Figure 1 shows the vibration speed diagram of single-stage helical gear drive under three different loads when the meshing impact is separately excited. It can be seen from the figure that: when the meshing impact is separately excited, obvious superharmonic resonance occurs at 1/3 and 1/2 resonant speeds N0; The root mean square value of relative vibration acceleration of helical gear increases with the increase of load; In the non resonant region, the vibration of helical gears increases significantly with the increase of rotating speed; In the over resonance region, the increase of rotating speed has a significant effect on the vibration characteristics of the system. This is because the meshing impact force increases with the increase of rotating speed, and the growth trend is approximately linear, which is consistent with the conclusion that the dynamic load coefficient Kv increases with the increase of helical gear pitch speed in the helical gear manual.

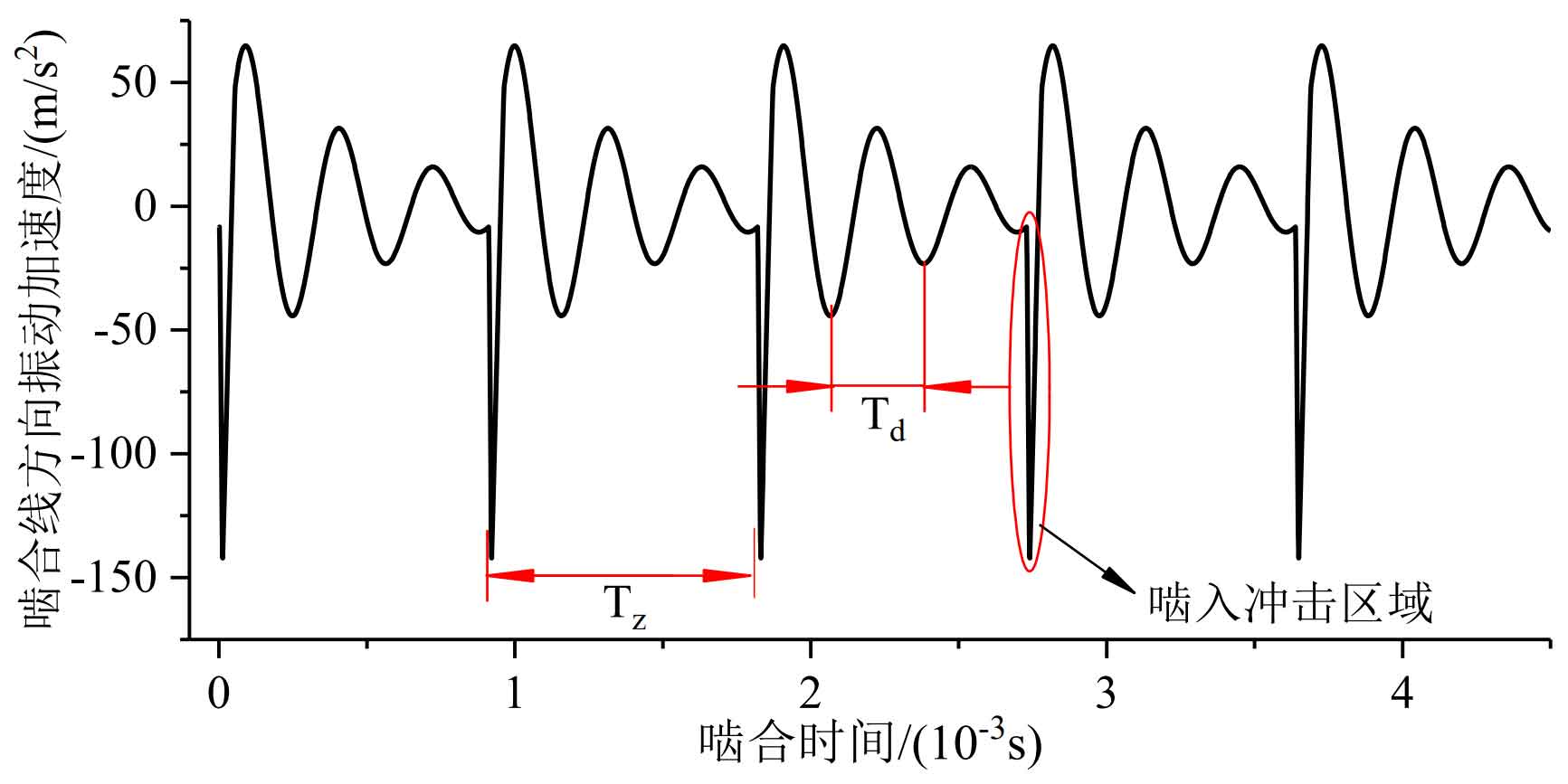

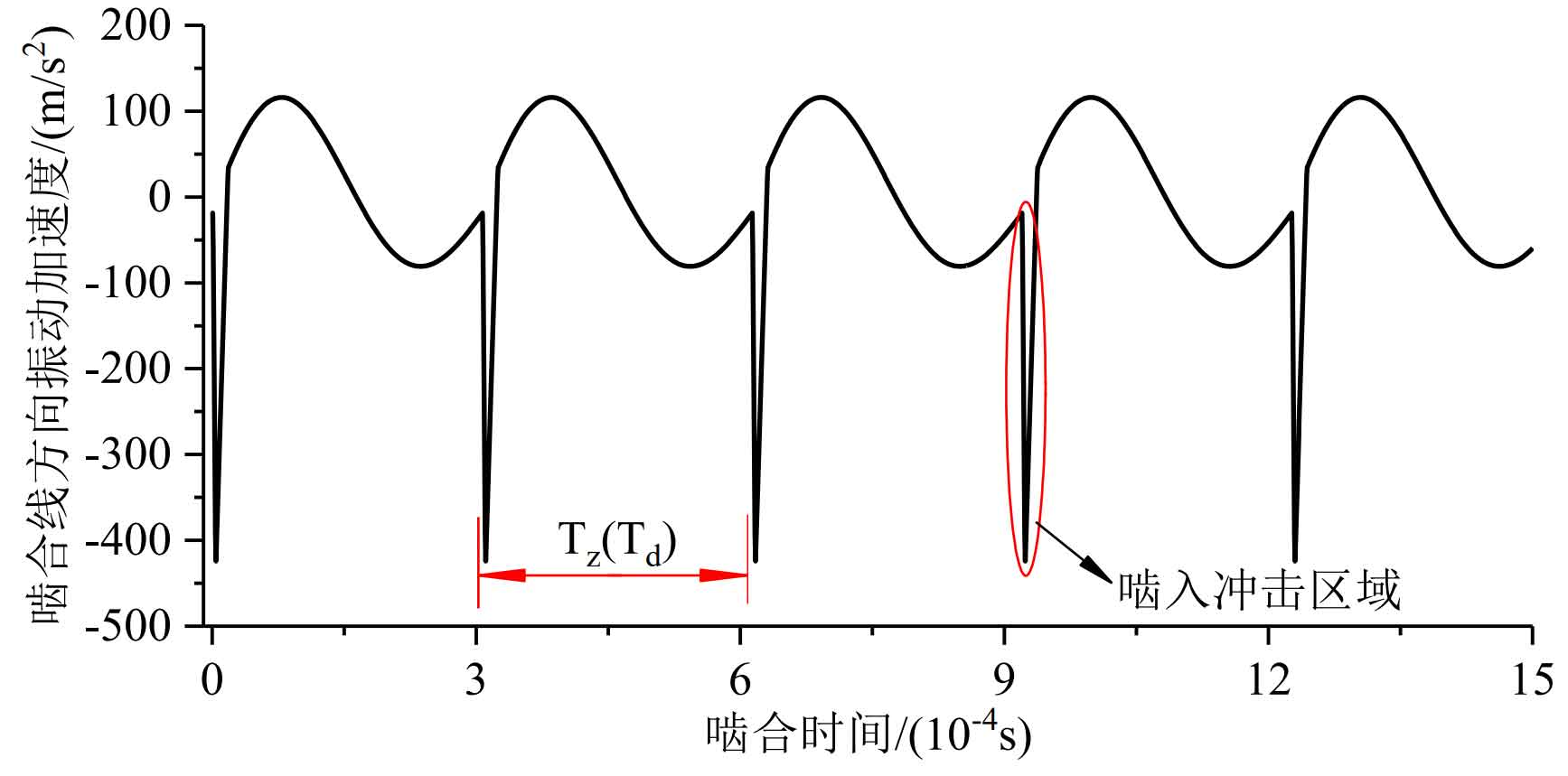

In order to study the time-domain and frequency-domain characteristics of helical gear transmission under separate excitation of meshing impact, the time-domain diagrams of the system at different speeds are made as shown in Figure 2 and Figure 3.

It can be seen in Figure 2 that the main feature of the meshing impact zone is the sudden change in the negative direction of the system vibration acceleration; This is because when the helical gear engages in the impact area, the speed of the driven gear will rise suddenly. According to the formula, the relative vibration acceleration in the direction of the meshing line of the helical gear end face will decrease sharply. In the figure, Tz is a meshing cycle. After the meshing impact is formed, the vibration acceleration of the system will gradually attenuate with Td as the cycle, and 1/Td is the natural frequency of the system; Because the meshing impact excitation contains more high-frequency components, the vibration acceleration of the system also attenuates rapidly. With the gradual increase of rotating speed, the meshing period Tz of helical gear also decreases. When the meshing period Tz is the same as the vibration acceleration attenuation period Td, the system will have resonance. As shown in Figure 3, the time domain diagram of 8900rpm under meshing impact excitation, where 8900rpm is the resonant speed of single-stage helical gear drive.

It can be clearly seen in Figure 3 that about one cycle Td after the previous impact will lead to the next impact, which is consistent with the analysis conclusion in Figure 3.