(1) Reverse engineering modeling technology construction curve

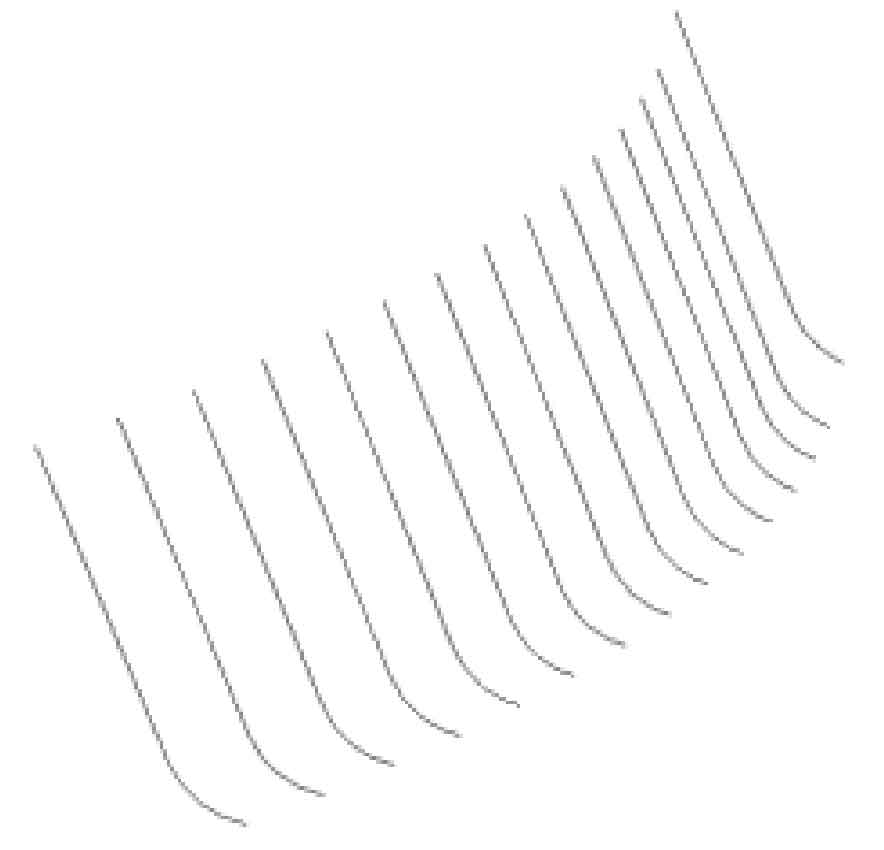

The principle is to use as few control points as possible under the condition of meeting the accuracy requirements. It can be seen from Figure 1 that the curvature of the point cloud slice line on the working tooth surface of the arc tooth surface gear changes little, so three control points are used in the construction of the curve.

(2) Construction of curved surface by reverse engineering modeling technology

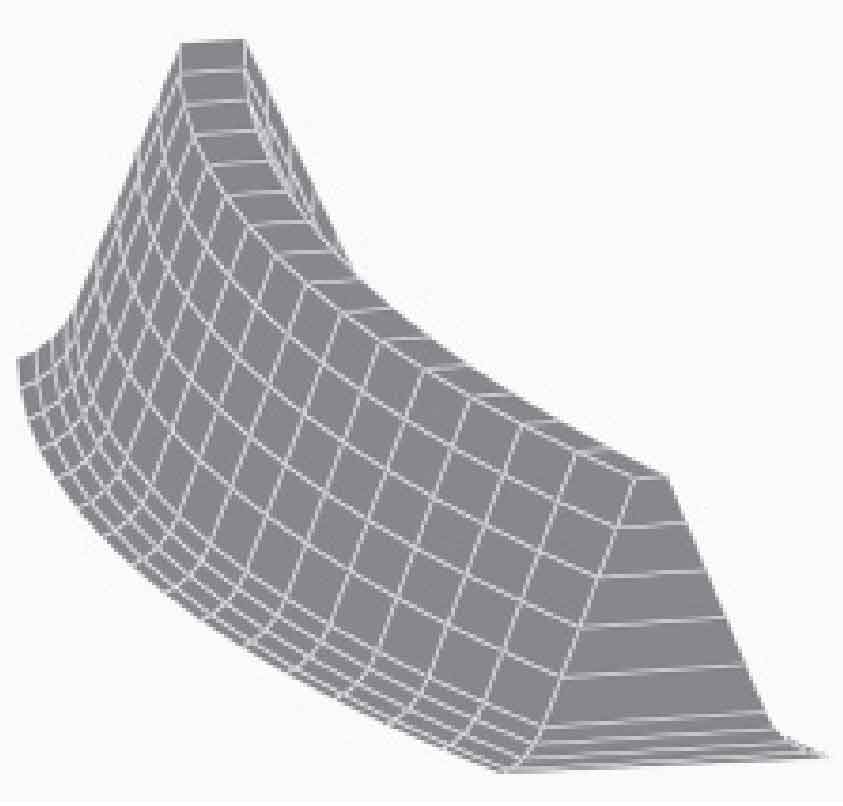

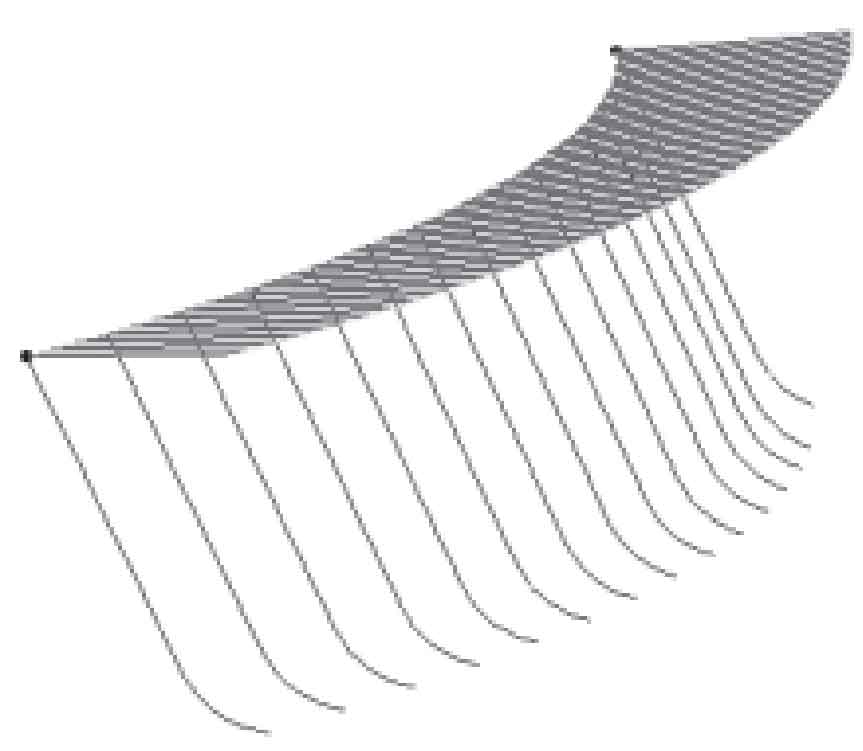

The principle is to use as few control curves as possible under the condition of meeting the accuracy requirements. According to the point cloud slice line, 8 curves are constructed along the tooth height direction, and each curve adopts 3 control points. It can be seen from Figure 2 that the curvature of the tooth surface of the arc tooth surface gear changes greatly along the tooth length direction. Therefore, a control curve is established along the tooth length direction, and five control points are adopted to ensure the continuity of its curvature as far as possible. The curvature analysis is shown in Figure 3.

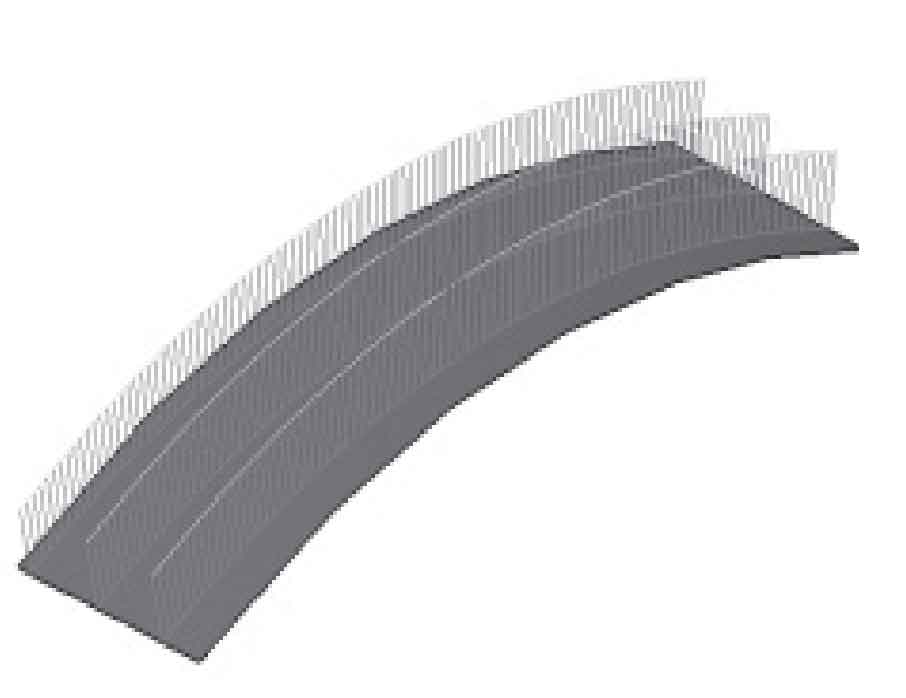

Because the curvature of the section along the tooth height direction changes little on the working tooth surface of the arc tooth surface gear, and the curvature change along the tooth length direction is basically the same, the multi-section sweeping function of CATIA software is used to construct the surface, the 8 curves constructed along the tooth height direction are used as the section line, and the control curve established along the tooth rectangle is used as the guide line. Detect the constructed surface and analyze the distance from the point cloud, and the maximum error is less than 0.001 mm; According to the curvature analysis of the surface, it can be seen from Figure 4 that the curvature changes of each section are basically the same.

The curvature of the working tooth surface of the arc tooth surface gear changes little along the tooth height direction, and the curvature changes more evenly along the tooth length direction. Therefore, the multi-section sweeping function is used to construct the surface. To construct a high-quality surface, we must first construct a high-quality curve; When constructing curved surface, the first thing is to control the tooth surface error. Secondly, the change of surface curvature should be continuous. Error analysis and curvature analysis shall be carried out after surface construction.