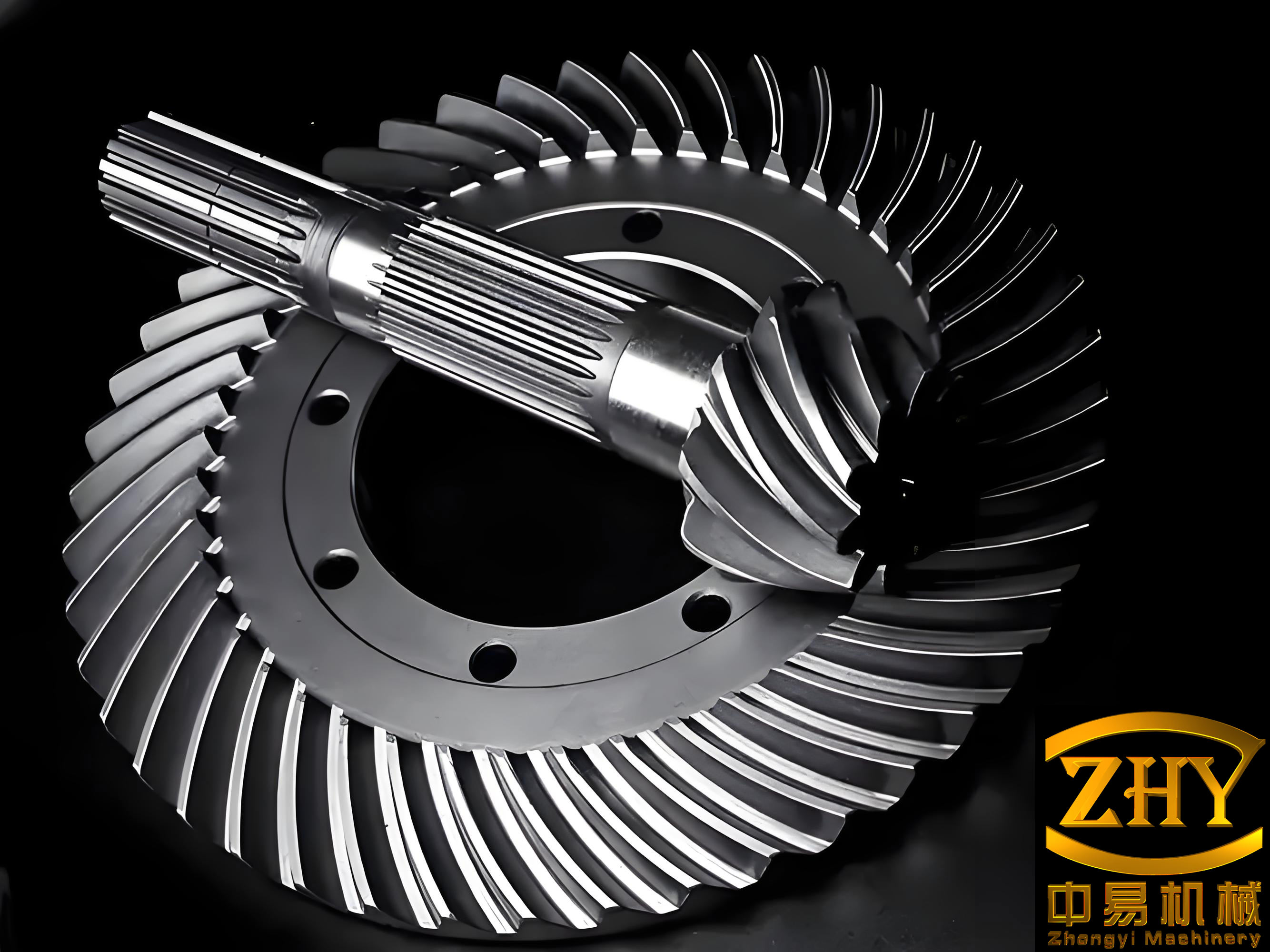

In my experience working with aerospace manufacturing, particularly in the context of aeroengine accessory drive systems, I have encountered persistent issues with the engagement quality of zero bevel gears. These gears, specifically the upper vertical and central transmission zero bevel gear pairs, often exhibit improper meshing during engine testing, leading to delays in delivery and potential safety concerns. Through extensive analysis and practical improvements, I have identified key factors contributing to these problems and implemented measures to enhance quality control. This article delves into the structural aspects, instability factors, and corrective actions, emphasizing the critical role of precision in manufacturing and inspection for zero bevel gears. I will use tables and formulas to summarize complex concepts, ensuring a comprehensive understanding of how to achieve optimal engagement in these critical components.

The accessory drive system of a typical aeroengine, which I have studied in depth, comprises several sections: central transmission, upper transmission, lower transmission, and transmission box drives. The central transmission transfers rotor motion to upper and lower accessory drives, while the upper transmission drives components like governors and starter-generators. Specifically, the zero bevel gears in the upper vertical and central transmission pairs are subjected to dual operational modes—start-up and work phases—where both tooth faces must meet stringent requirements. This dual functionality makes them prone to quality inconsistencies, as I have observed in multiple engine trials. For instance, during start-up, the starter-generators impart torque, and any misalignment in the zero bevel gears can cause localized adhesion wear on the start-up tooth faces, compromising performance. The complexity of these systems necessitates a thorough examination of gear geometry and assembly tolerances.

One of the primary issues I have documented is the frequent occurrence of improper meshing in zero bevel gear pairs, manifesting as adhesive wear on the start-up surfaces. This phenomenon, as illustrated in wear patterns, often results in the need for replacement gear pairs and repeated testing, highlighting the urgency of addressing root causes. In my analysis, I attribute this to several factors, including the unique structural characteristics of zero bevel gears, limitations in inspection methods, and deviations in housing dimensions. Unlike cylindrical gears, zero bevel gears involve spherical involute surfaces that require three-dimensional calculations, making them more sensitive to installation distances and shaft angles. For example, the installation distance $ \Delta d $ for a zero bevel gear pair must satisfy the condition for equal module in the meshing plane: $$ m_1 = m_2 $$ where $ m_1 $ and $ m_2 $ are the modules of the mating gears. If this is not maintained, it leads to uneven contact patterns and increased stress concentrations.

To better understand the instability factors, I have categorized them into key areas, as summarized in the table below. This table outlines the main contributors to engagement issues in zero bevel gears, based on my observations and data collected from engine tests.

| Factor | Description | Impact on Zero Bevel Gear |

|---|---|---|

| Structural Support | Zero bevel gears often have cantilevered supports, allowing 360° deflection under load. | Increases sensitivity to misalignment and vibration. |

| Installation Distance Sensitivity | Deviations in $ \Delta d $ cause unequal module in meshing profiles. | Leads to improper contact patterns and reduced load capacity. |

| Inspection Methods | Reliance on coloring checks and point-based measurements. | Subjectivity in coloring interpretation can mask errors. |

| Housing Tolerances | Dimensional and geometric inaccuracies in bearing seat holes. | Alters shaft angles and installation distances, exacerbating meshing issues. |

The特殊性 of zero bevel gear inspection cannot be overstated. In my work, I have found that coloring checks, which involve applying a dye to the tooth surfaces and observing the contact patterns under a torque of approximately 10 N·m, are crucial for assessing meshing quality. However, this method is highly dependent on operator experience and visual estimation, with resolutions only down to about 0.1 mm. The ideal contact pattern for a zero bevel gear should be elliptical, covering about 80% of the tooth surface without heavy contact at the edges. Mathematically, the contact ratio $ C_r $ for a zero bevel gear can be expressed as: $$ C_r = \frac{L}{p} $$ where $ L $ is the length of contact and $ p $ is the circular pitch. Ensuring $ C_r > 1 $ is vital for smooth operation, but deviations in tooth geometry can reduce this ratio, leading to noise and wear.

In recent years, advanced inspection techniques like coordinate measuring machines (CMM) have been adopted for zero bevel gears, using point-based data collection across 45 points on the tooth surface. This method aims to quantify deviations from a standard gear, with tolerances typically set at ±0.007 mm. However, in my experience, over-reliance on point data without complementary coloring checks has led to quality issues. For instance, the formula for the deviation $ \delta $ at any point can be given by: $$ \delta = \sqrt{(x_i – x_s)^2 + (y_i – y_s)^2 + (z_i – z_s)^2} $$ where $ (x_i, y_i, z_i) $ are the coordinates of the inspected point and $ (x_s, y_s, z_s) $ are the standard coordinates. When $ \delta $ exceeds thresholds, it indicates potential meshing problems. Yet, I have observed that even with point accuracies improved to ±0.003 mm, without proper coloring validation, zero bevel gears may still exhibit engagement faults. This highlights the need for a balanced approach in quality control.

Another critical aspect I have investigated is the influence of housing dimensions on zero bevel gear performance. The bearing seat holes in the accessory housing and central transmission frame must maintain tight tolerances for shaft angles and installation distances. Any deviation, such as positional errors exceeding specifications, can misalign the gears, leading to uneven load distribution. For example, the shaft angle $ \Sigma $ between mating zero bevel gears should ideally be 90°, but tolerances can cause variations described by: $$ \Sigma = \Sigma_0 \pm \Delta \Sigma $$ where $ \Sigma_0 $ is the nominal angle and $ \Delta \Sigma $ is the tolerance. If $ \Delta \Sigma $ is too large, it results in edge loading and accelerated wear. In one case, I measured housing bore position errors that, when corrected, resolved pre-existing meshing issues in zero bevel gears, underscoring the importance of geometric precision.

To address these challenges, I have implemented several improvements in the manufacturing and inspection processes for zero bevel gears. Firstly, for the central transmission zero bevel gears, I revised the acceptance criteria to prioritize coloring checks over point-based measurements. This involved re-inspecting all existing gear pairs and selecting those with optimal contact patterns. The results showed a significant reduction in meshing problems. Secondly, for the upper vertical zero bevel gears, I adjusted machining parameters to enhance point accuracy to ±0.003 mm and made coloring the primary acceptance criterion. The table below summarizes the key improvements and their outcomes based on my applied changes.

| Improvement Measure | Description | Impact on Zero Bevel Gear Engagement |

|---|---|---|

| Enhanced Coloring Checks | Made coloring the main acceptance method, with adjustments to installation distance. | Improved contact patterns and reduced adhesive wear incidents. |

| Increased Point Accuracy | Reduced CMM tolerance from ±0.007 mm to ±0.003 mm for major gears. | Better replication of standard gear geometry, minimizing deviations. |

| Housing Tolerance Tightening | Improved dimensional and geometric tolerances for bearing seats. | Enhanced alignment, leading to more uniform meshing under load. |

| Paired入库 for Critical Gears | Ensured gears are stored and inspected as matched pairs. | Reduced variability in meshing performance during assembly. |

Furthermore, I introduced mathematical models to optimize the coloring process for zero bevel gears. The contact pattern can be analyzed using the equation for tooth surface pressure distribution $ P(x,y) $: $$ P(x,y) = \frac{F_n}{A_c} \cdot e^{-\alpha (x – x_0)^2 – \beta (y – y_0)^2} $$ where $ F_n $ is the normal force, $ A_c $ is the contact area, $ \alpha $ and $ \beta $ are constants related to tooth curvature, and $ (x_0, y_0) $ is the center of contact. By controlling these parameters through machining adjustments, I achieved more consistent coloring results. For instance, in one batch of zero bevel gears, after fine-tuning the pressure angle and spiral angle, the contact patterns met specifications, and engine tests confirmed satisfactory engagement.

In conclusion, my work demonstrates that ensuring the engagement quality of zero bevel gears in aeroengines requires a holistic approach combining precise manufacturing, rigorous inspection, and continuous improvement. The zero bevel gear, with its complex geometry and sensitivity to assembly conditions, demands that coloring checks remain a cornerstone of quality control, supplemented by advanced point-based measurements. By tightening tolerances and emphasizing paired inspections, I have mitigated many of the issues that previously plagued these components. As aerospace technology evolves, further research into digital twins and real-time monitoring could enhance zero bevel gear reliability. Ultimately, the lessons learned here apply broadly to high-precision gearing systems, underscoring the importance of integration between design, production, and validation phases for optimal performance.

Reflecting on this journey, I realize that the zero bevel gear serves as a microcosm of broader challenges in aerospace manufacturing. Its performance hinges on the interplay of multiple variables, each requiring meticulous attention. For future developments, I recommend adopting standardized protocols for zero bevel gear inspection and investing in training to reduce subjectivity in coloring assessments. Additionally, leveraging simulation tools to model meshing dynamics could preempt issues before physical testing. The zero bevel gear, though a small part of the engine, plays a critical role in overall system integrity, and by addressing its nuances, we can achieve higher standards of safety and efficiency in aviation.