3D model reconstruction mainly uses the point cloud data on the model surface collected by spiral bevel gear reverse engineering to construct a model similar to the real object through interpolation or fitting. There are two methods as follows: one is the surface reconstruction method, which synthesizes the spiral bevel gear reverse engineering point cloud data by interpolation or approximation fitting, and then constructs the surface with the curve; The second is to use point cloud data to simulate and synthesize surface patches, and then simulate and synthesize surface patches through transition, splicing, cutting and other operations. Here, the surface is constructed from point to line, and then from line to face.

Pro / E software can carry out complex model modeling. It can process the data files in STL format of Geomagic Studio software and IGS format of Imageware software, complete the construction of surface, materialize it, and finally realize re modeling.

1. Curve generation

Save the spiral bevel gear reverse engineering point cloud data file processed by Imageware software into IGS format. In Pro / E, the IGS file is imported by opening the command, and the points on a curve are connected successively by passing through points through the curve command to complete the construction of one curve, and the rest of the curves are constructed by this method.

2. Surface reconstruction

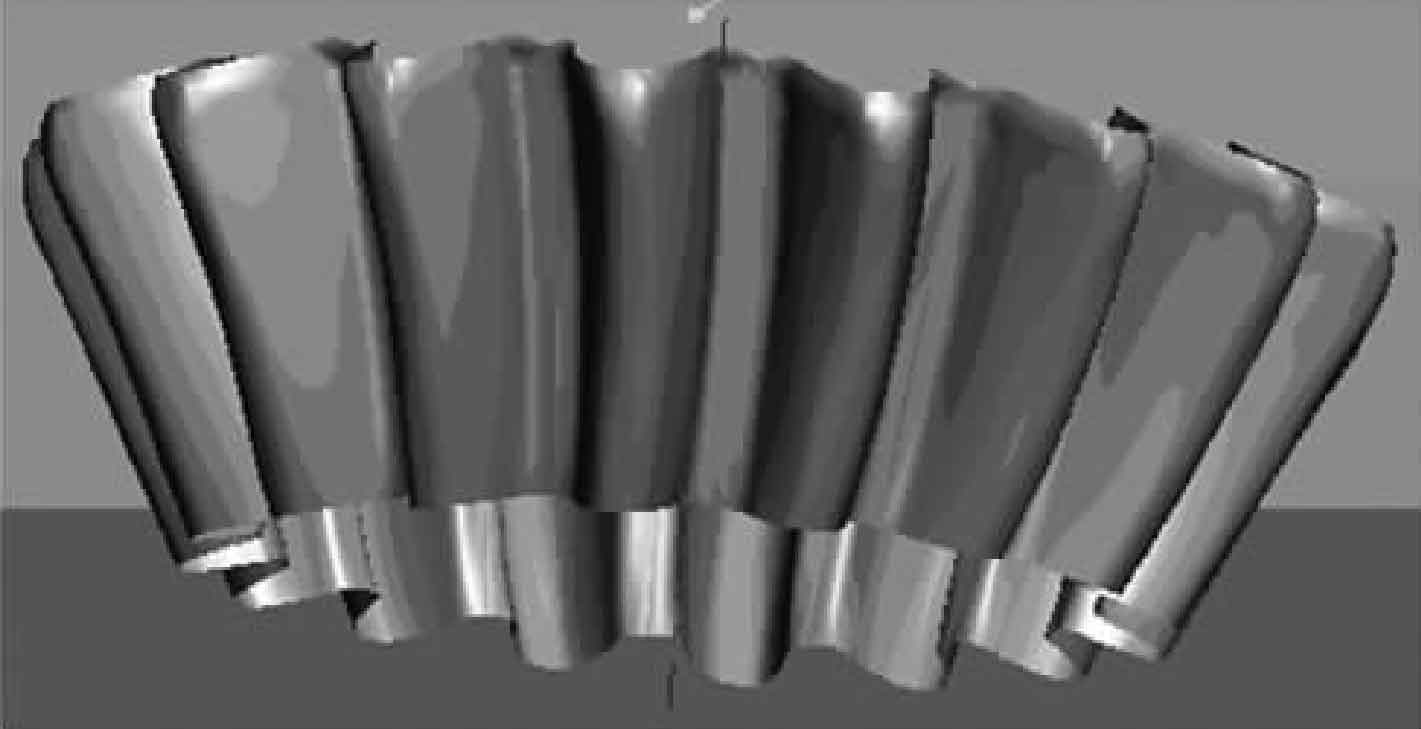

In Pro / E, select the curves in turn through the boundary blend command to build the model surface. The constructed tooth surface is arrayed to obtain the whole tooth surface of spiral bevel gear. The reconstructed tooth surface model of spiral bevel gear is shown in Figure 1.

3. Reconstruction of 3D model

Firstly, the constructed surface is materialized, a reference shaft is constructed according to the end face circle of spiral bevel gear, the constructed teeth are arrayed through the array command, and then the other parts of spiral bevel gear are constructed with Pro / E according to other relevant dimensions measured by vernier caliper, and finally a complete three-dimensional model of spiral bevel gear is obtained. Thus, the reconstruction of spiral bevel gear model is realized. The three-dimensional model of spiral bevel gear is shown in Figure 2.