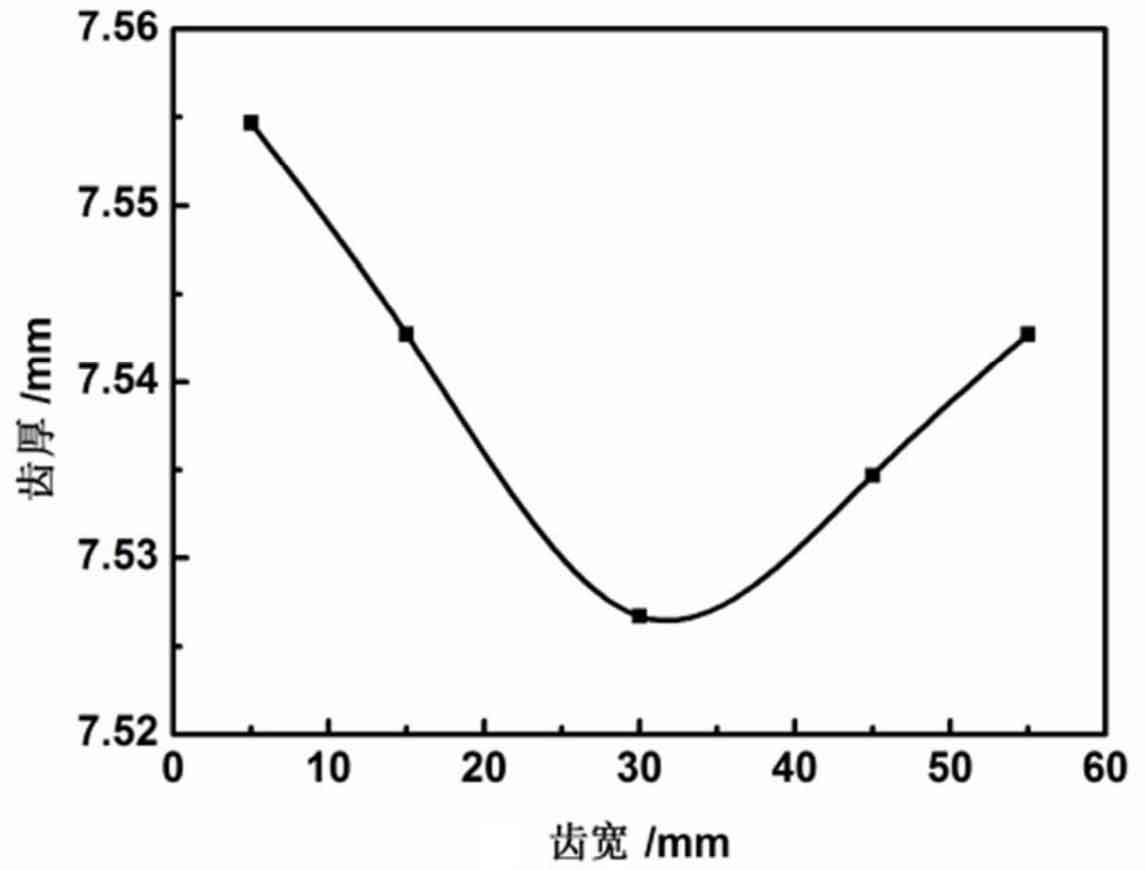

In previous studies, the ideal model without error is used in the numerical simulation of cold shaping of spur gear. The accuracy of spur gear is grade 0, which is quite different from that of spur gear after actual cold extrusion. It belongs to shaping “good gear” into “bad gear”. In order to be close to the reality, the common normal micrometer is used to measure the dimension data of tooth thickness on the effective tooth width. Three extruded spur cylindrical gears are randomly selected. The common normal micrometer is used to measure the common normal dimensions of five groups of different sections along the tooth width across three teeth. Each section measures three groups of different teeth and calculates the average value. After conversion, the change of tooth thickness along the tooth width direction is obtained. As shown in Figure 1, the change of tooth thickness of cold extruded spur gear along the tooth width direction is shown. The tooth thickness in the middle of cold extruded spur gear is less than that at both ends, the tooth thickness at the first extruded end at the lower end is the largest, and the tooth thickness in the middle is 0.03mm less than that at the first extruded end.

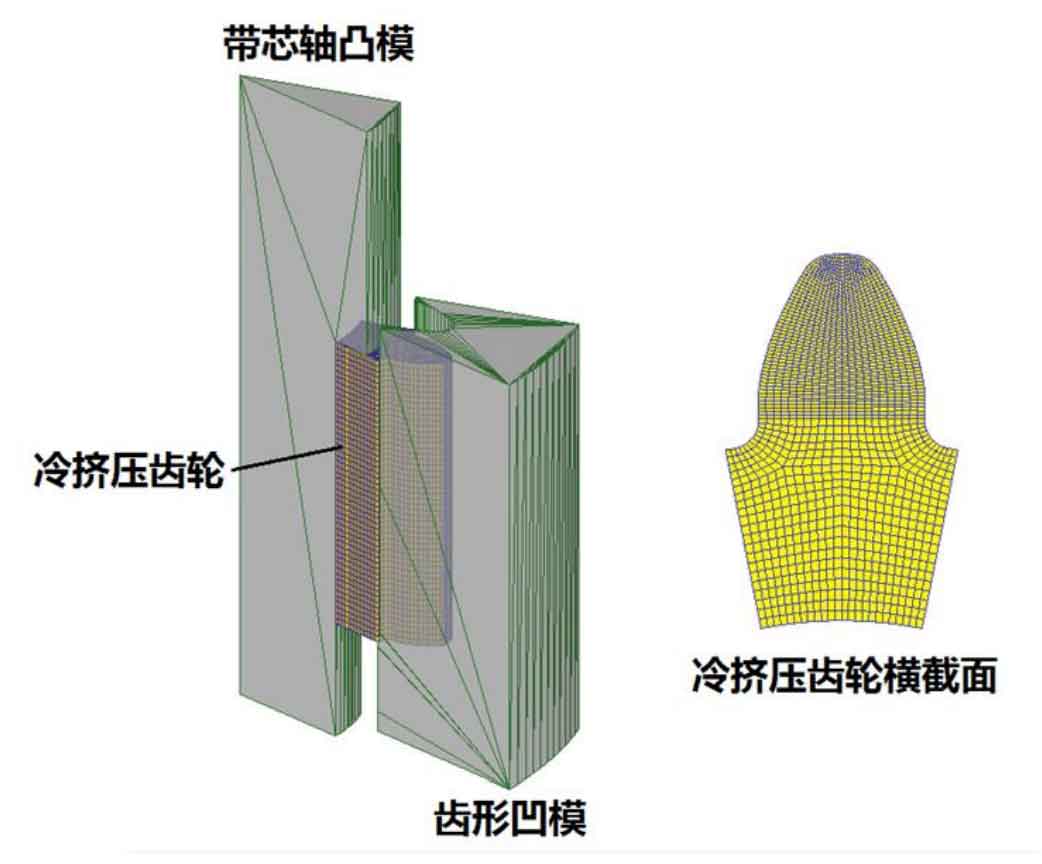

The three-dimensional model and finite element model of different cold shaping methods are established based on the measured data, as shown in Figure 2. Because cold shaping is a small deformation, the cold extruded spur gear is defined as an elastic-plastic body and the die is defined as a rigid body, ignoring the elastic deformation and temperature effect of the die. In order to reduce the calculation time, take a single tooth for simulation, and the blank material is 20CrMnTi. In order to improve the calculation accuracy, use hyper mesh software to divide the hexahedron mesh of cold extruded spur gear, refine the tooth profile locally, and output the key file readable by deform.

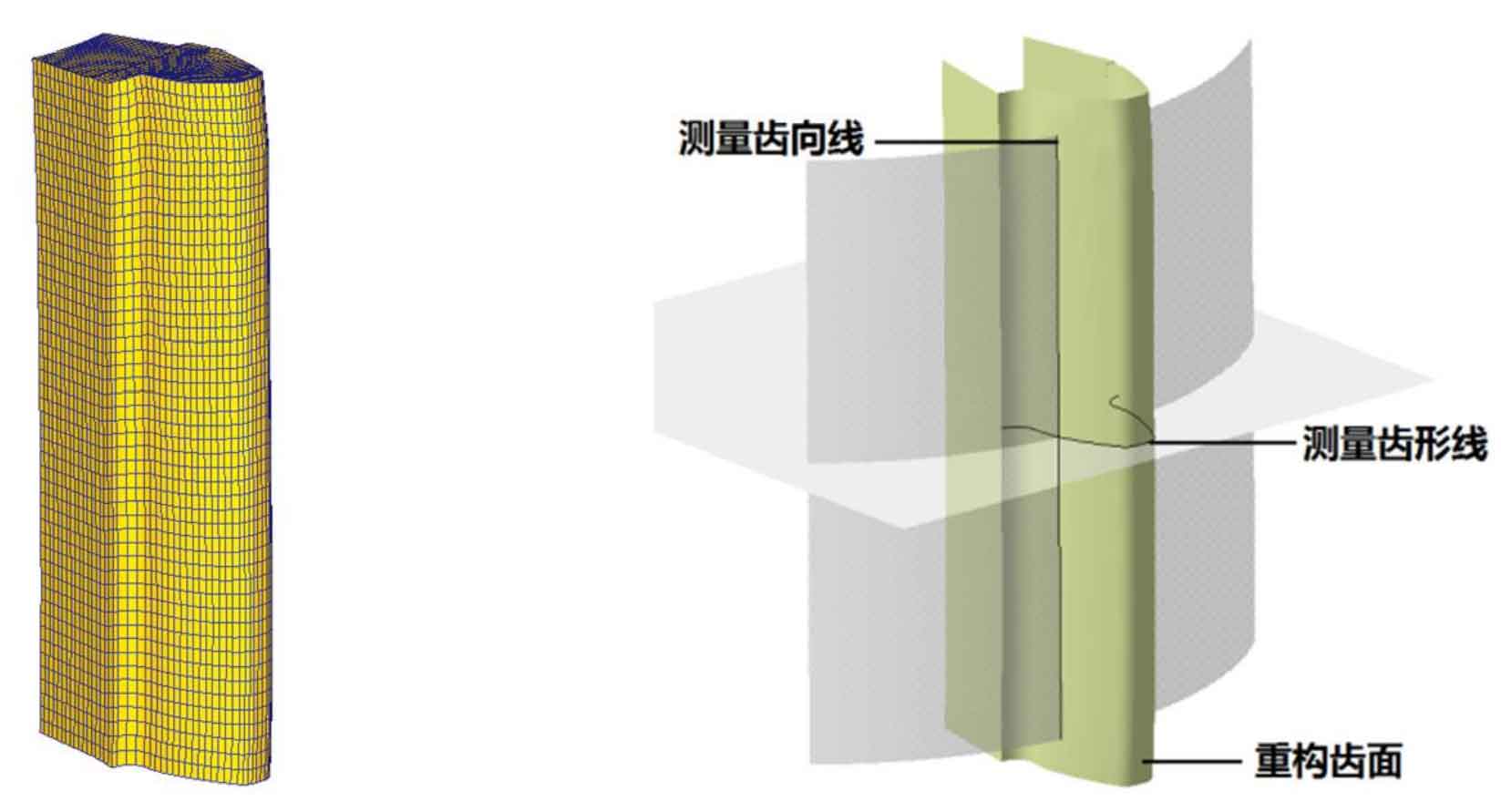

Fig. 3 (a) shows the simulation results after cold shaping. Point tracking is carried out for all grid nodes on the tooth surface, the coordinate information of all nodes after cold shaping is extracted and imported into CATIA for tooth surface reconstruction, and the total deviation of tooth profile and helix of spur cylindrical gear after shaping by different cold shaping methods and different shaping quantities are measured, as shown in Fig. 3 (b).