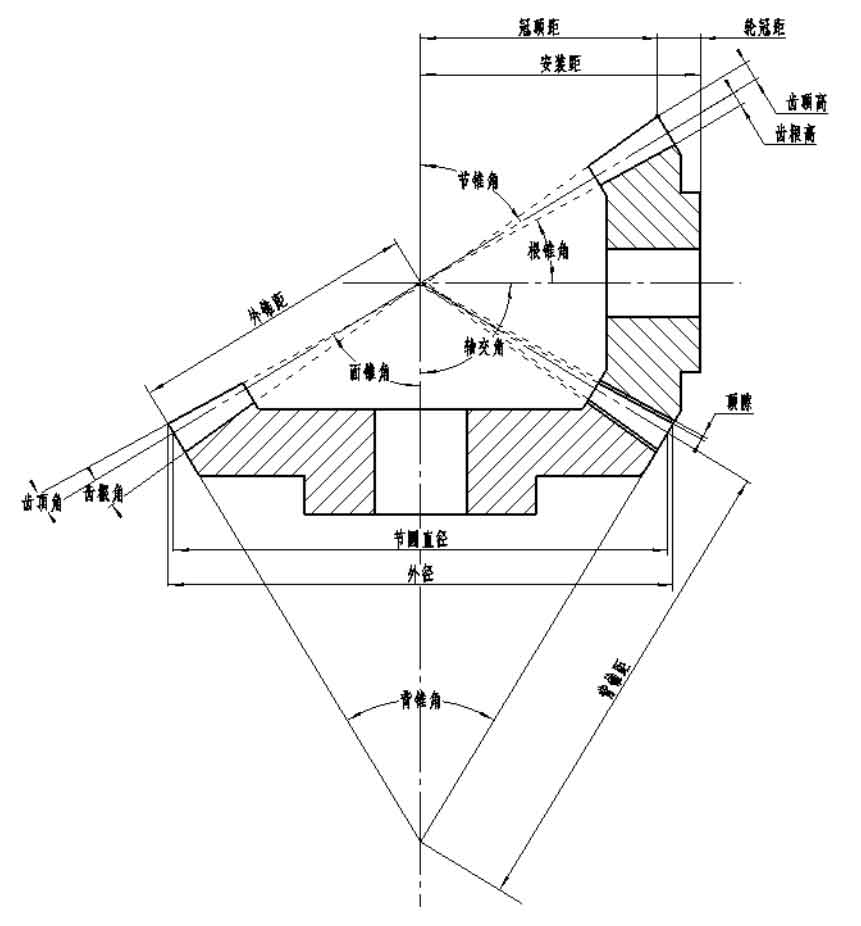

The geometric dimension of the wheel blank is the basis for the design and processing of the spiral bevel gear blank. The spiral bevel gear generally adopts the standard shrinkage tooth, that is, the height of the tooth is gradually reduced in proportion from the outer end to the inner end, and the pitch cone vertex of the gear coincides with the root cone vertex. The standard shrinkage tooth is also used in this paper.

The pitch cone is very important in the geometric dimension of spiral bevel gear, and it is also a necessary dimension in the modeling process. The pitch cone is equivalent to a pair of pure rolling friction cones in the transmission process of spiral bevel gear pair. It is formed by the rotation of the instantaneous axis around the spiral bevel gear axis in the relative motion of spiral bevel gear pair. The common tangent plane of the two friction cones is the pitch plane of the spiral bevel gear pair. Pitch cone angle is the half cone angle of pitch cone, and the two pitch cone vertices of spiral bevel gear coincide.

The basic parameters and value taking methods of spiral bevel gear pair are described as follows:

1.The shaft intersection angle Σ and transmission ratio I are selected or calculated according to the transmission requirements of spiral bevel gear pair. The countershaft intersection angle Σ of spiral bevel gear is generally 90 °, and other angles can be selected under special circumstances, but the pitch cone must intersect at one point; The transmission ratio I is determined by the number of large and small gear teeth, and its value is equal to the number of large gear teeth Z2 / the number of small gear teeth Z1.

2.According to the power and torque transmitted by the required spiral bevel gear pair, determine the pitch diameter D1 and the number of teeth Z1 (no less than 5) of the small wheel at the outer end of the small wheel through empirical formula or chart. The outer end modulus m of spiral bevel gear can be determined according to the Formula M = D1 / Z1, and the outer end modulus can be non integer.

3.The number of teeth of the large wheel Z2 = iz1 is rounded after calculation, and the sum of the number of teeth of the large wheel and the small wheel is not less than 40, that is, Z1 + Z2 ≥ 40.

4.Determination of tooth surface width B. Check the table and take the smaller of 10m and 0.3 outer cone distance, which is generally ≤ 30% outer cone distance. I.e. B ≤ 30% RE

5.Determine the rotation direction of spiral bevel gear according to the rotation direction of large wheel and small wheel. The rotation direction of the large and small wheels of the spiral bevel gear pair is determined according to the transmission requirements. In order to ensure that the spiral bevel gear pair has an axial force pushing away from each other in the meshing process, the large wheels of the spiral bevel gear are generally right-handed.

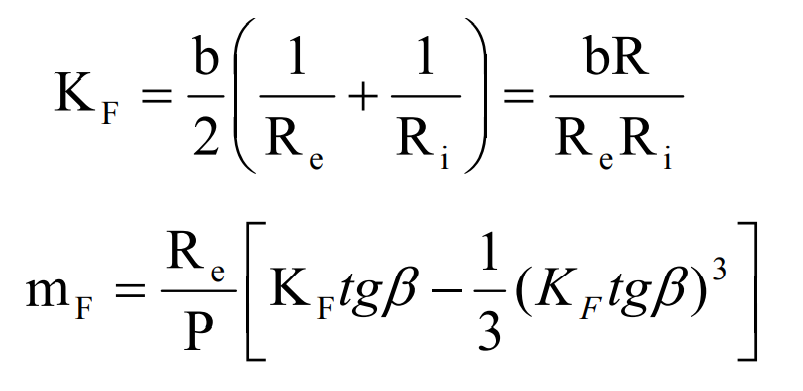

6.In order to ensure that the spiral bevel gear pair has a certain degree of coincidence, the appropriate helix angle should be selected. Larger helix angle can improve the coincidence degree of spiral bevel gear pair, but it has an impact on strength and wear, so 35 degrees is generally selected. The appropriate helix angle can also be selected according to the experience table; The coincidence degree can be calculated according to the formula. In the formula: B is the tooth width, re is the outer cone distance, R is the midpoint cone distance, RI is the inner cone distance, and MF is the end face coincidence.

7.Determine the pressure angle. The pressure angle is generally 16, 19, 20, 21.5, 22.5, 25 degrees, etc. too small pressure angle will reduce the strength of spiral bevel gear and prone to undercutting, but the flexibility will increase; If the pressure angle is too large, the tooth top will become sharp and the coincidence degree will be reduced. The use of small pressure angle can reduce noise and smooth operation, such as spiral bevel gear of car drive axle; The use of a large pressure angle can increase the strength of spiral bevel gear pair. For example, trucks generally use a large pressure angle, so the pressure angle needs to be selected by combining various factors. Spiral bevel gear is generally 20 degrees.

8.Addendum height coefficient, backlash coefficient and backlash. By looking up the table, generally, when the number of small gear teeth Z1 ≥ 12, the tooth top height coefficient is 0.85 and the top clearance is 0.188, then the working tooth height coefficient is 1.7 and the full tooth height coefficient is 1.888. Side clearance check table selection.

9.Selection of displacement coefficient. According to the transmission ratio and the number of teeth of spiral bevel gear, it can be obtained by looking up the table. The geometric parameters of the gear blank of spiral bevel gear are shown in the figure.