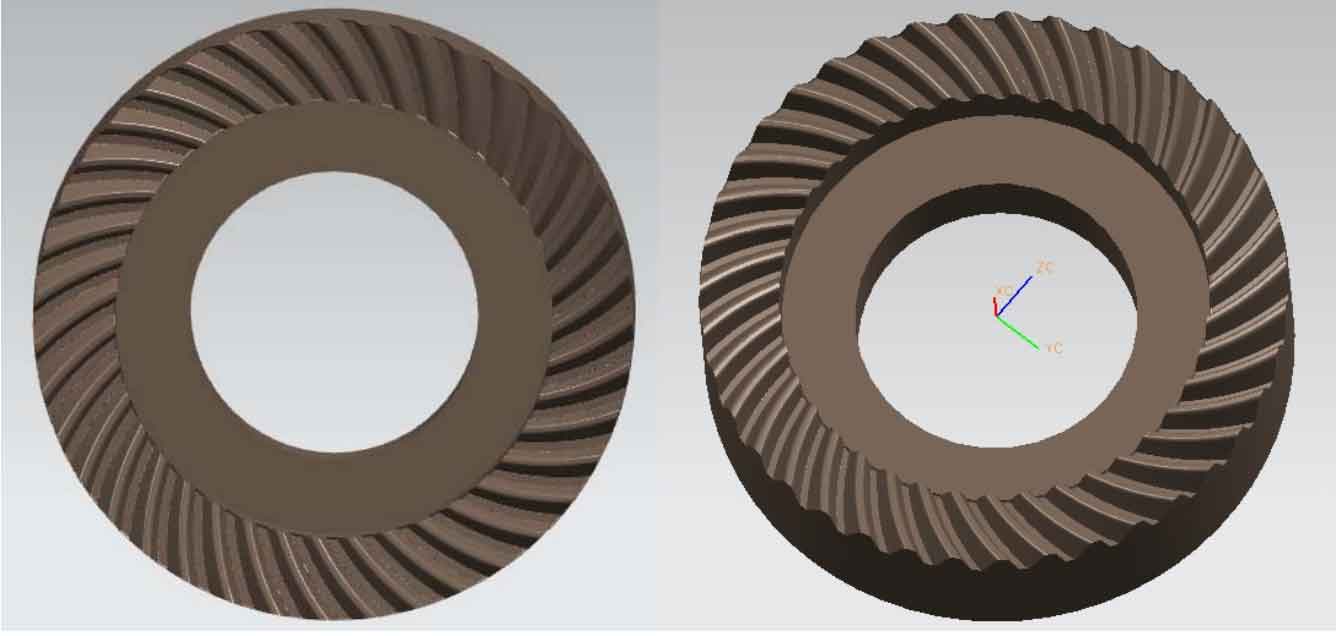

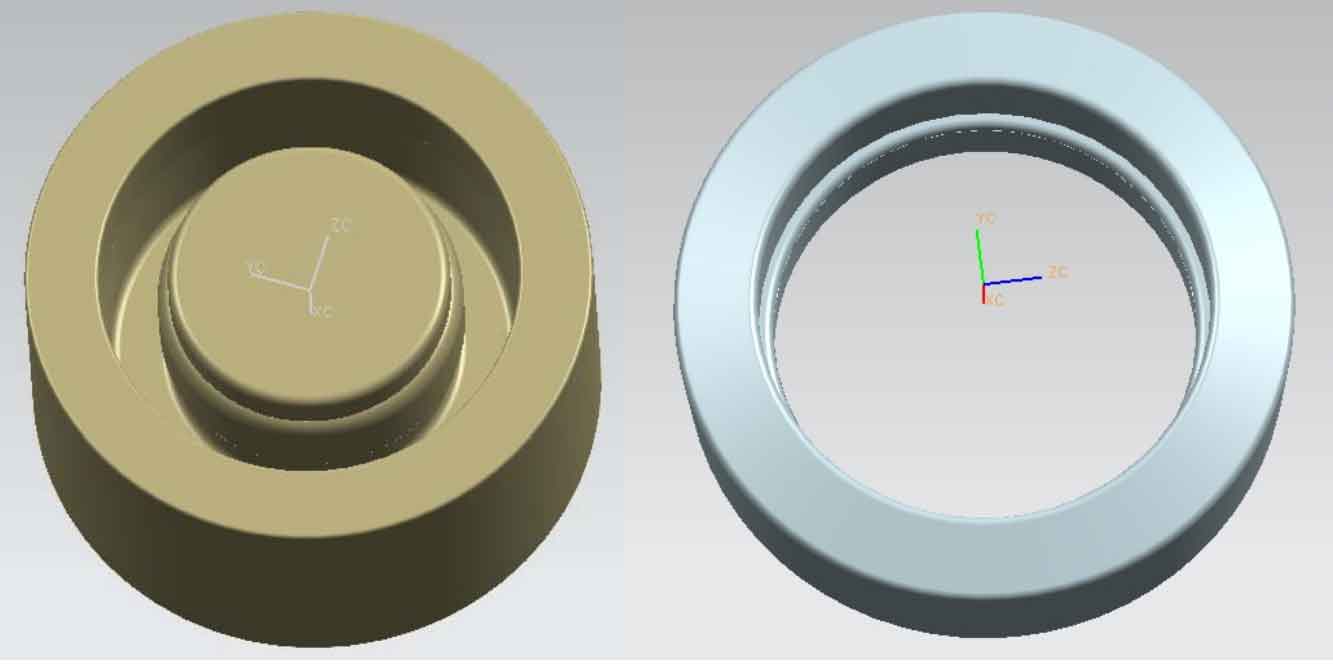

The hot forging simulation forming process of spiral bevel gear wheel is similar to the cold forging process. The model of forming die and blank is shown in Figure 1.

It can be seen from the stroke load curve of the simulation results in Chapter 4 that the tonnage of the press required for the cold precision forging of the same spiral bevel gear is large. The spiral bevel gear forging simulation is carried out according to the geometric parameters of the medium modulus tooth profile. It is considered to use the spiral bevel gear hot forging cold finishing for processing. The simulation process is hot forging first, leaving a small part of the finishing allowance, The shape of spiral bevel gear forging with accurate shape is obtained by shape trimming through cold forging die. The process is as follows:

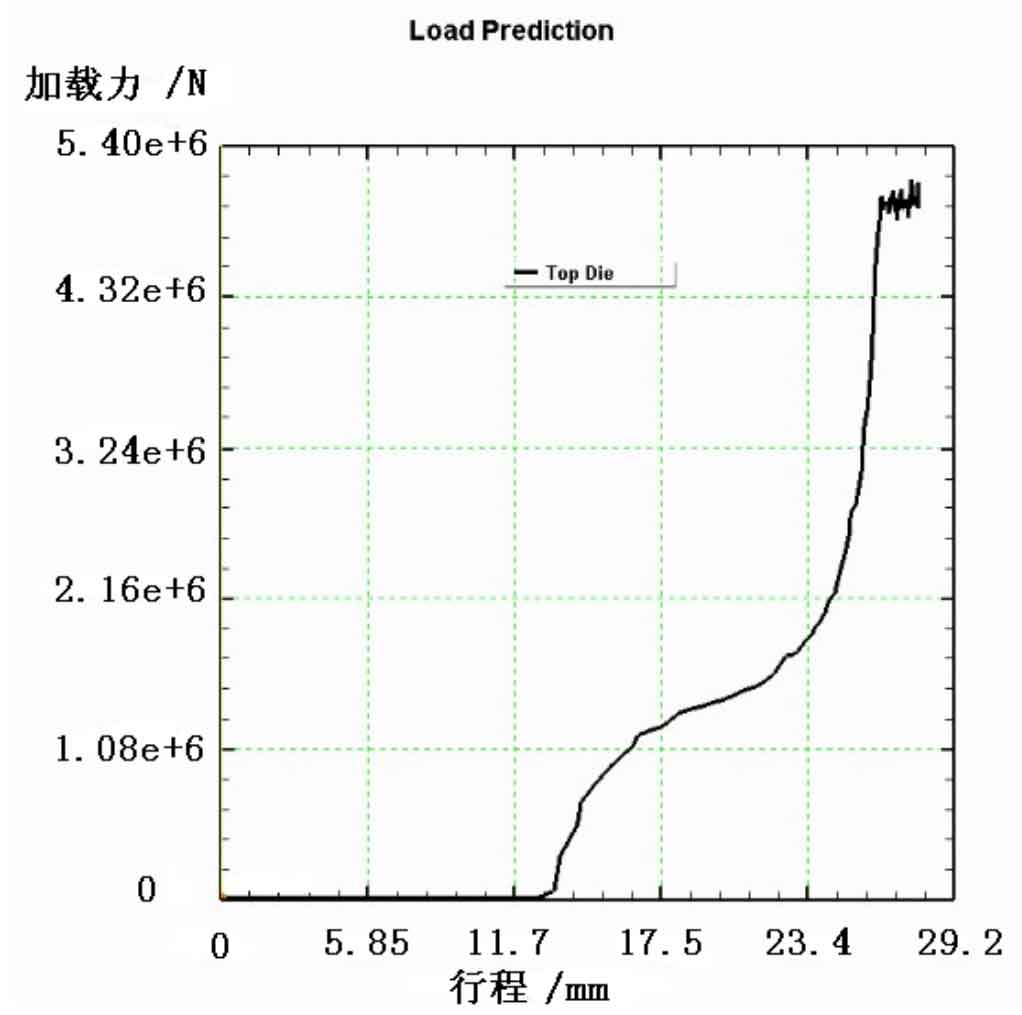

The setting and meshing of the imported three-dimensional model are similar to the small module cold forging of spiral bevel gear. The simulation temperature is 1050 ℃, the friction coefficient is 0.3, and other settings are similar to the small module cold forging. Then, a runnable file is generated, and the hot forging die simulation results are obtained by running the file. There is little difference between the hot forging process of spiral bevel gear and cold forging. During the forming process, there are no folds or defects on the tooth surface, and the tooth shape is well formed. Theoretically, the final loading force of the same spiral bevel gear in the hot forging process should be less than that in the cold forging. The stroke load curve of this hot forging process is shown in Figure 2.

It can be seen from Fig. 2 that the mold and blank begin to contact when the mold moves about 11.7mm, and then the mold loads the blank. At the beginning of the curve, the slope is large, and the loading force increases obviously. This part should be the initial state of blank forming due to mold accident. At the beginning, the deformation resistance of the blank is large, and then the slope gradually decreases, and the increase of loading force slows down, This part is the gradual forming stage of gear teeth. Then, the curve slope increases again, and the loading force increases rapidly. This part corresponds to the last stage of the forming process of gear teeth. Finally, the loading force jumps at a certain position, which corresponds to the contact between the upper and lower molds and elastic deformation. The forming of gear teeth is completed, and other positions change slightly under the loading force, The hot forging process of spiral bevel gear is over.

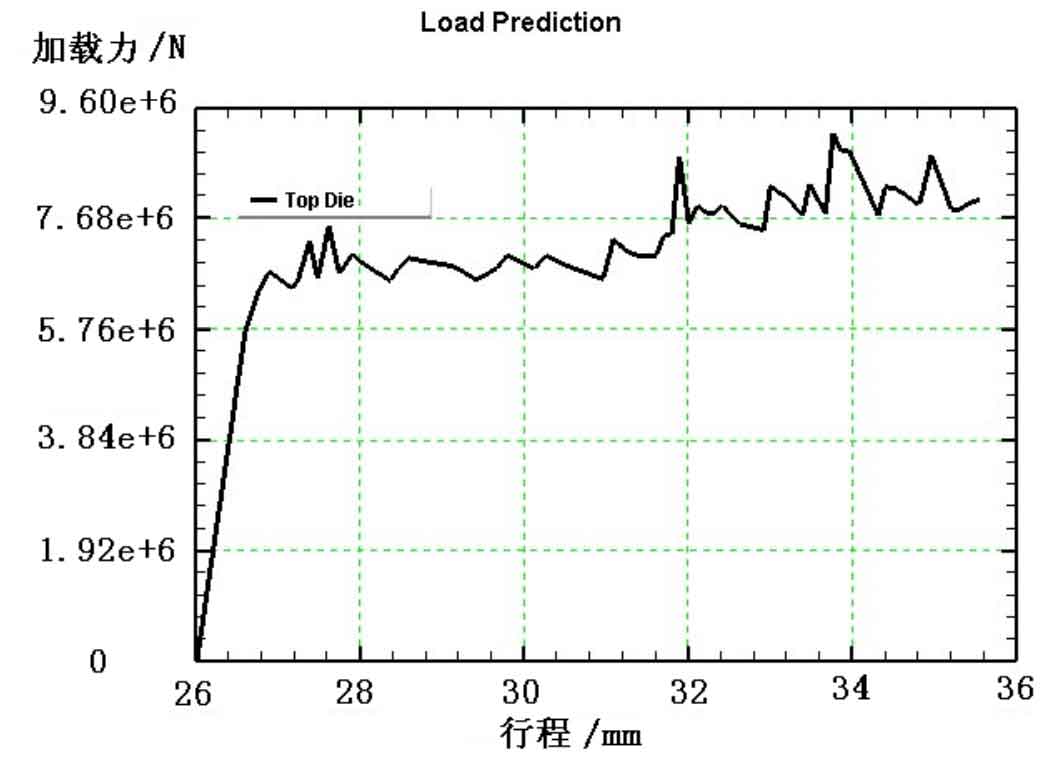

The hot forging of spiral bevel gear is used as the blank of cold finishing, the temperature is set to 20 ℃ at room temperature, the friction coefficient is changed to 0.12, and other parameters remain unchanged. The finishing process is simulated, and the stroke load curve of the process is obtained, such as:

As can be seen from Fig. 3, when the cold finishing process of spiral bevel gear first reaches the stroke of about 27mm from the stroke of about 26mm, the slope of the loading force curve is large, and the loading force increases sharply, and then the loading force fluctuates around 700000n. After analysis, the sharp increase of the loading force is due to the initial stage of tooth profile trimming of the blank by the die, Then, when the loading force fluctuates, the die has been in contact with most of the blank, the blank is gradually deformed under the die pressure, and the final tooth profile correction is completed.

From the peak value of stroke load curve, the final load of spiral bevel gear hot forging reaches 5000000n. According to this theoretical value, the tonnage of press should be more than 500 tons, and the average load in finishing process is 7500000n ~ 9000000n. Press with more than 1000 tons can be selected. Most spiral bevel gear forging factories have this experimental condition.