Warm forging is equivalent to the pre forming step of spur gear. The design of pre forging drawing is based on the drawing of final forging, with a certain final machining allowance, i.e. cold finishing allowance. The warm forging process is carried out at a certain temperature, and the thermal expansion characteristics of the blank must be considered. In addition, the diameter of the center hole of the spur gear is 57mm, so the through hole cannot be forged directly on the forging, and the connecting skin must be reserved in the hole.

1. Design of cold finishing allowance

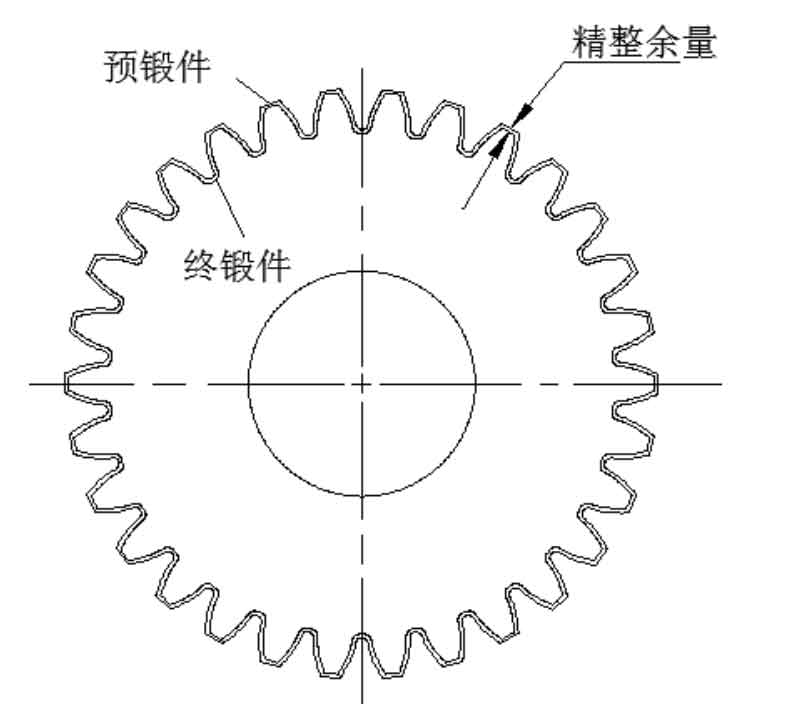

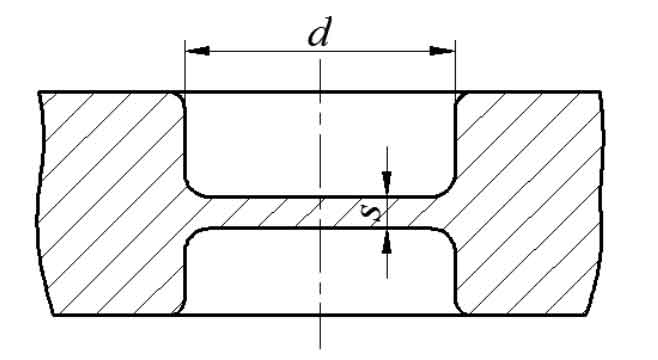

The cold finishing process of spur gear after warm forging is used to improve the service life, dimensional accuracy and surface quality of precision forgings. Cold forging belongs to a small deformation process. As shown in Figure 1, the schematic diagram of cold finishing quantity is shown. The allowance is too small, and the proportion of elastic deformation of forgings is large, which can not achieve the purpose of finishing. If the allowance is too large, the extrusion force will increase and the die will be seriously worn, which will affect the machining accuracy.

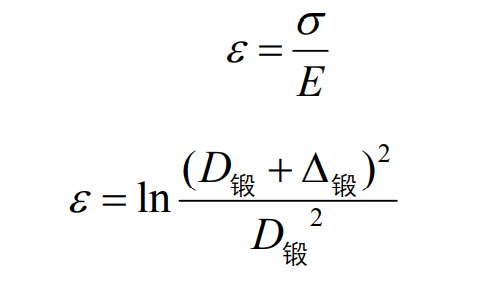

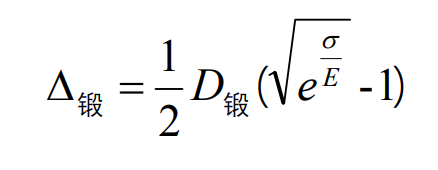

Considering that the cold forging adopts the elastic-plastic finite element model, the elastic deformation of the forging can not be ignored, and the cold finishing amount must be greater than the elastic deformation of the forging, otherwise the purpose of finishing cannot be achieved. Considering the elastic recovery of spur gear forgings after cold working Δ Forging, according to generalized Hooke’s Law:

The unilateral elastic strain of forging is:

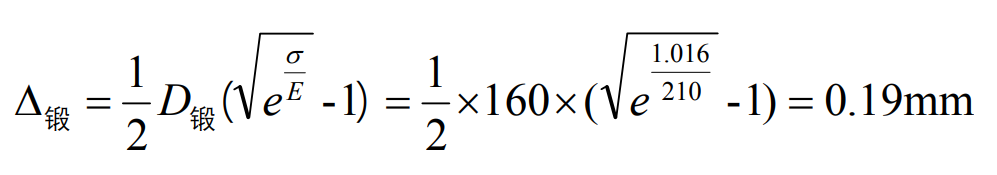

According to the tensile test, the yield limit of 18crnimo is 1016mpa and the young’s modulus is 210gpa. The unilateral allowance calculated by bringing into the above formula is:

0.2mm unilateral finishing allowance shall be reserved for the contour part of the straight tooth cylindrical gear after warm forging.

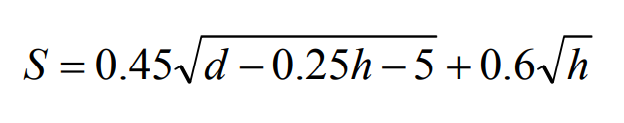

2. Design of connecting skin

When the diameter of the spur gear hole is greater than 30mm, the shape of the hole needs to be forged during warm forging, but the through hole cannot be obtained directly. A thin layer of metal should be left and cut in the punching process. The hole diameter of the spur gear is 57mm, and the height of the spur gear is 26mm. The form of skin connection is flat bottom skin connection, as shown in Figure 2. Its size is calculated according to the formula, and the thickness of skin connection during warm forging is determined to be 6 ~ 7mm.

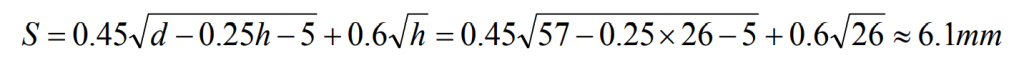

For the spur gear, the skin thickness:

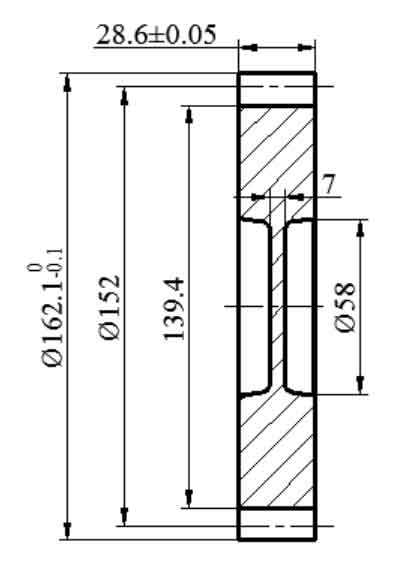

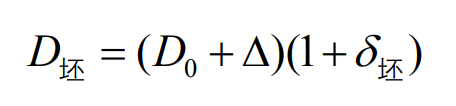

3. Thermal deformation

Warm forging takes place at a certain temperature, and the material expands when heated. In order to ensure the processing accuracy of pre forging, the influence of thermal deformation should be considered during warm forging. When designing the die cavity, the size of blank and die caused by temperature rise should not be considered according to the size of part drawing. The warm forging temperature of spur gear is 850 ℃, and the thermal expansion coefficient of 18crnimo7-6 at 850 ℃ is 1.17 × 10-5。 Bring the material parameters into the formula, calculate the thermal expansion of the blank, and obtain the hot forging of spur gear, as shown in Figure 3.

Where:

D0 – basic dimension;

D – blank size after thermal expansion;

δ Billet – thermal deformation of billet;

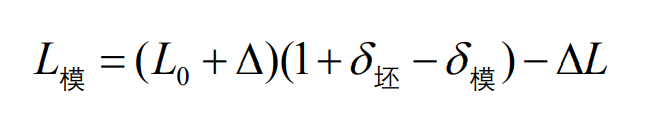

The calculation of warm forging die can not be based on the size of hot forging drawing, but also consider the thermal expansion of die itself. During pre forging, the preheating temperature of the die is 250 ℃, the material is H13, and the coefficient of thermal expansion is 1.21 × 10-5, bring in the formula for calculation.

Where:

L die – die cavity size;

L0 – Basic Dimension of die;

Δ— Cold finishing quantity;

δ Die – thermal deformation of die;

Δ L – absolute value of elastic deformation of die cavity size;

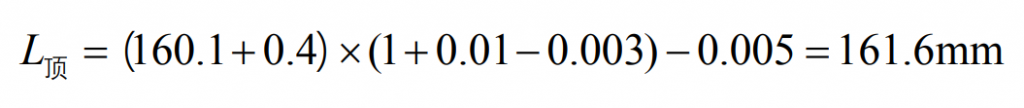

Take the addendum circle of spur gear as an example: