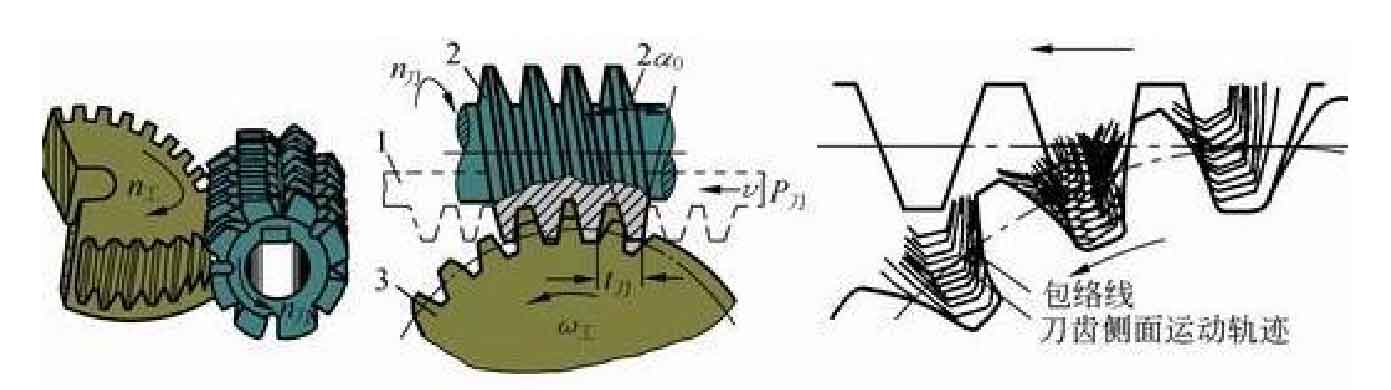

The machining principle of gear hobbing is shown in Figure 1.

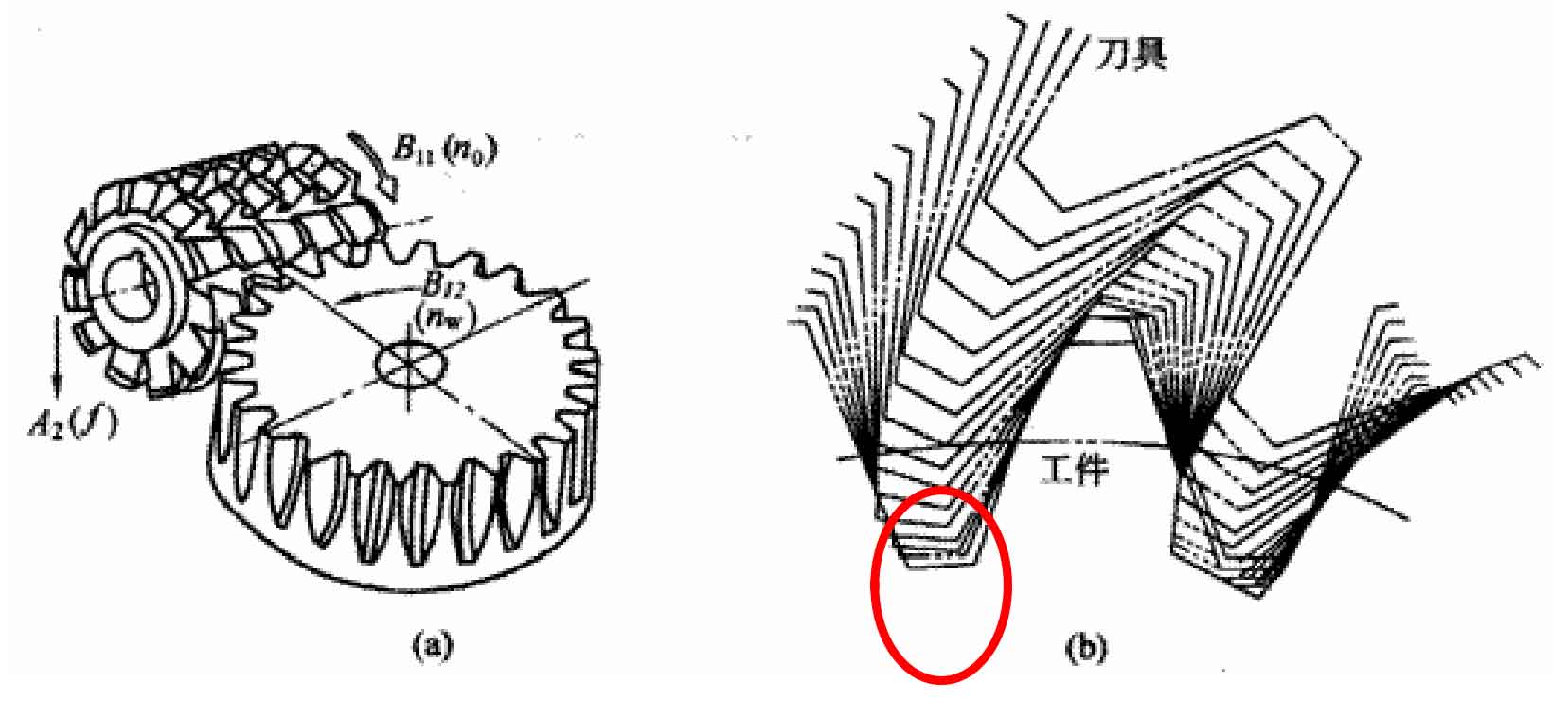

Theoretically, during gear hobbing, the gear hobbing hob meshes with the gear, continuously cuts the gear, and finally processes the ideal gear; In the actual machining process, the gear hobbing cutter does not cut the gear workpiece continuously, but intermittently, as shown in Figure 2.

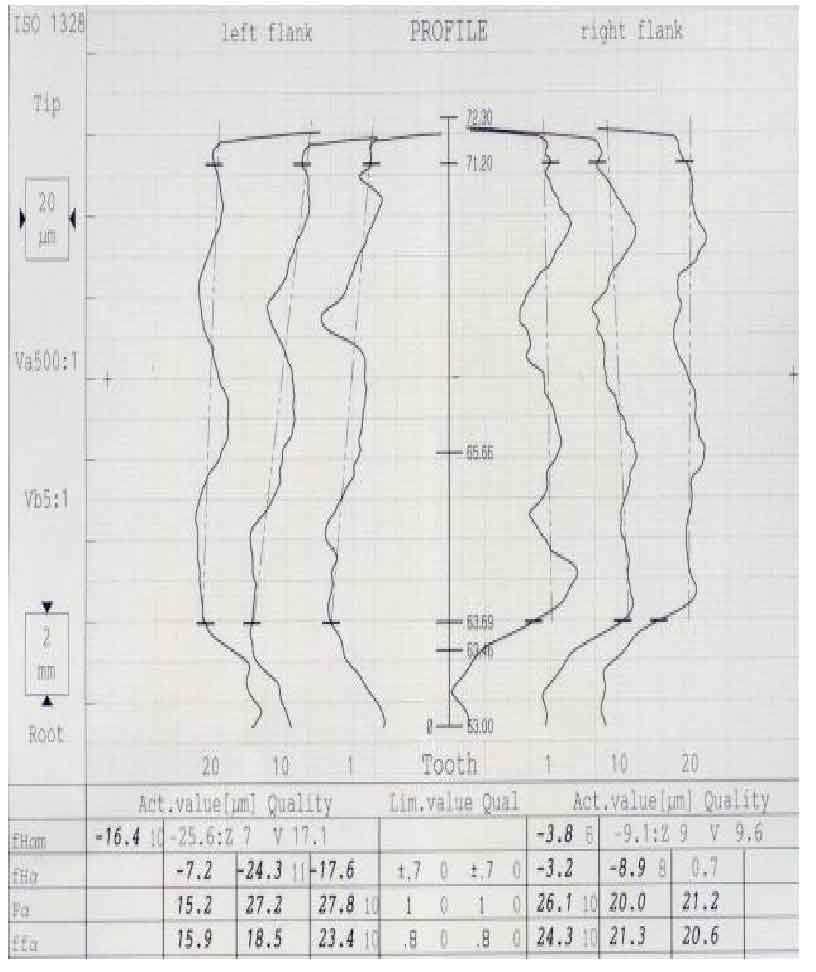

As shown in Figure B, the gear hobbing hob has multiple cutter heads to cut the workpiece intermittently, which leads to the serrated tooth profile error caused by intermittent cutting in the gear hobbing process; At the root of the tooth, the tooth profile error is processed by the gear hobbing hob tip in the process of two adjacent gear hobbing hobs, so the detected tooth profile is partial to sawtooth; The tooth profile error at the top of the tooth is processed by the gear hobbing hob surface on one side of the gear hobbing hob during two adjacent cutting processes. The detected tooth profile sawtooth is not very obvious. As shown in Figure 3, the sawtooth edge of the tooth profile can be clearly seen. Next, we analyze the error.