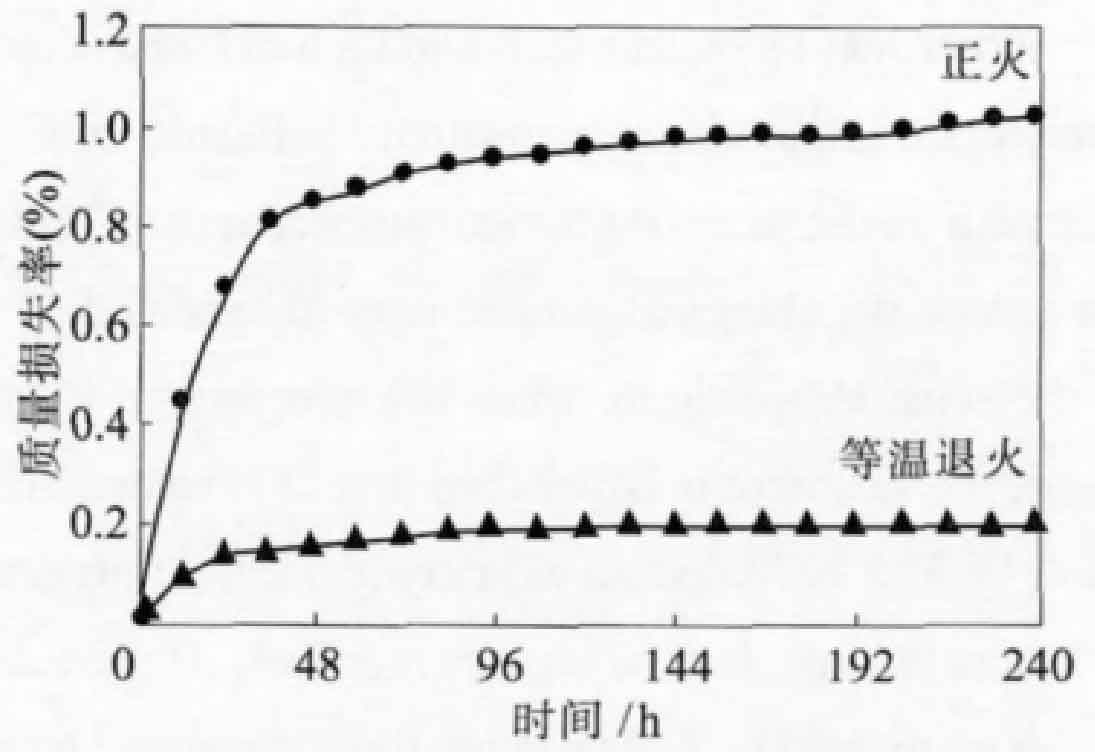

The mass loss rate time curve of automotive gear test materials after normalizing and isothermal annealing in 0.6mol/l NaCl solution is shown in the figure.

It can be seen that the mass loss of automotive gear test materials in NaCl solution after normalizing is greater than that of isothermal annealing. The mass loss rate increased linearly within 48 hours of the beginning of corrosion. When the total immersion corrosion lasts for 240 h, the mass loss rate reaches 1.02%. The mass loss rate of the automotive gear test material after isothermal annealing is 0.20% when it is fully immersed for 240 h, which is much lower than that of the normalized sample.

The mass loss rate of isothermal annealing treatment is lower than that of normalizing treatment in NaCl solution, and the corrosion resistance of the material is stronger. This is consistent with the salt spray corrosion test results of the material.