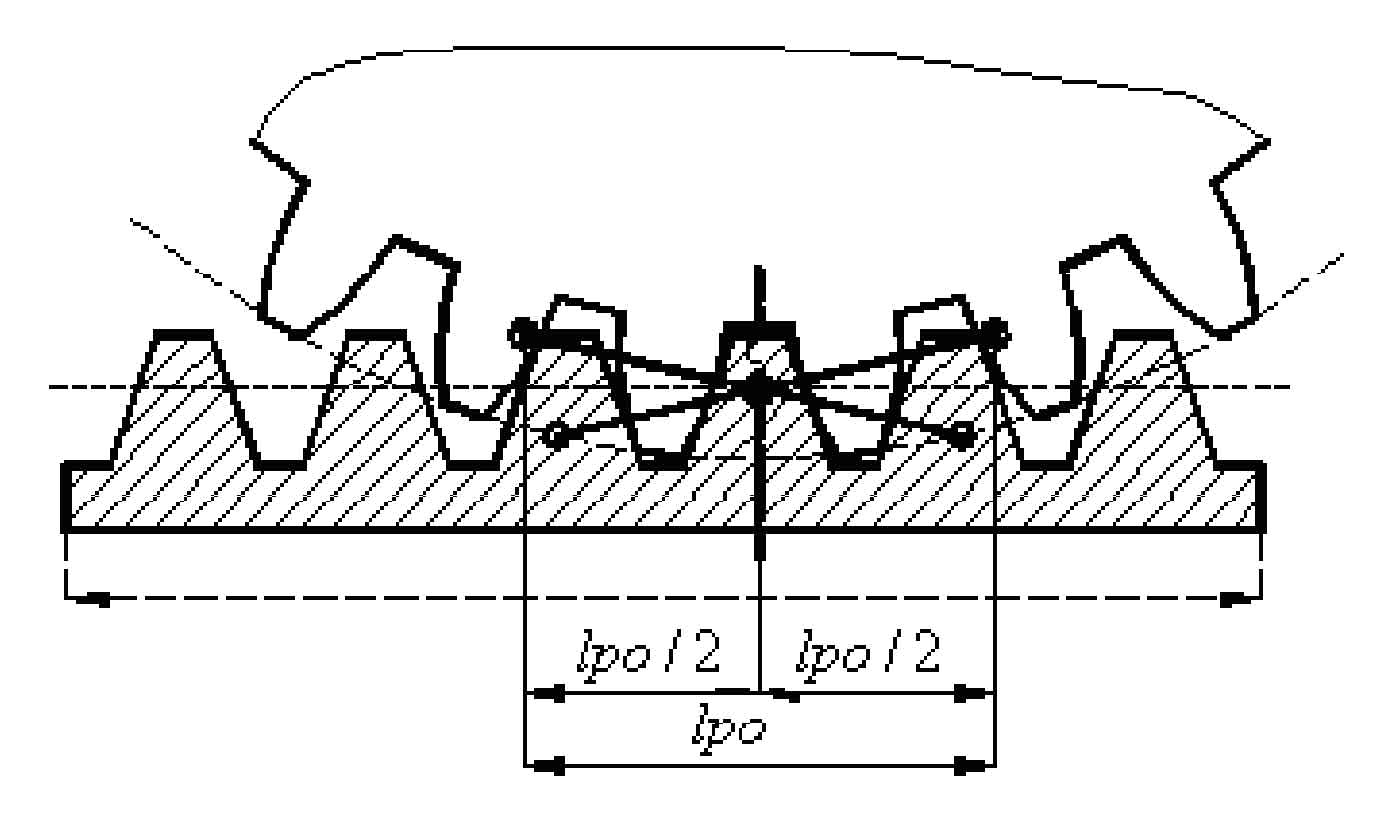

The calculation method of the length of the generating area of gear hobbing hob is shown in Figure 1. If:

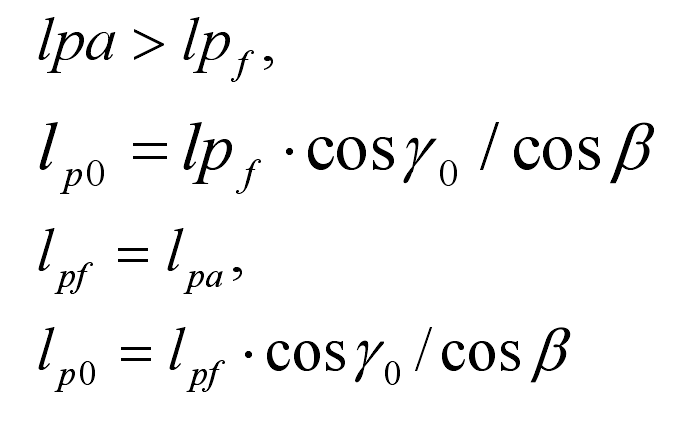

In the figure:

Where

Hao — tooth top height of gear hob;

X · Mn — displacement;

ρ Ao — fixed arc radius of gear hob;

α—— Pressure angle;

β—— Helix angle;

Z — number of teeth;

Mn — modulus;

Da — diameter of gear top circle;

γ 0 – spiral rising angle of gear hobbing hob.

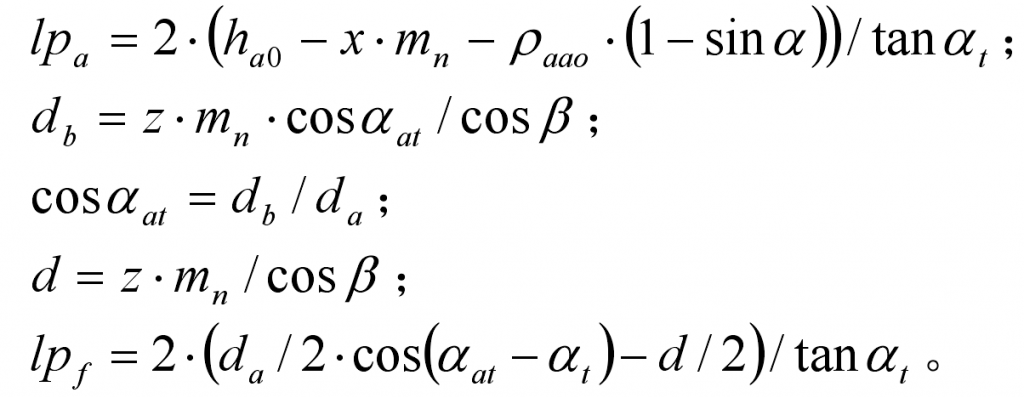

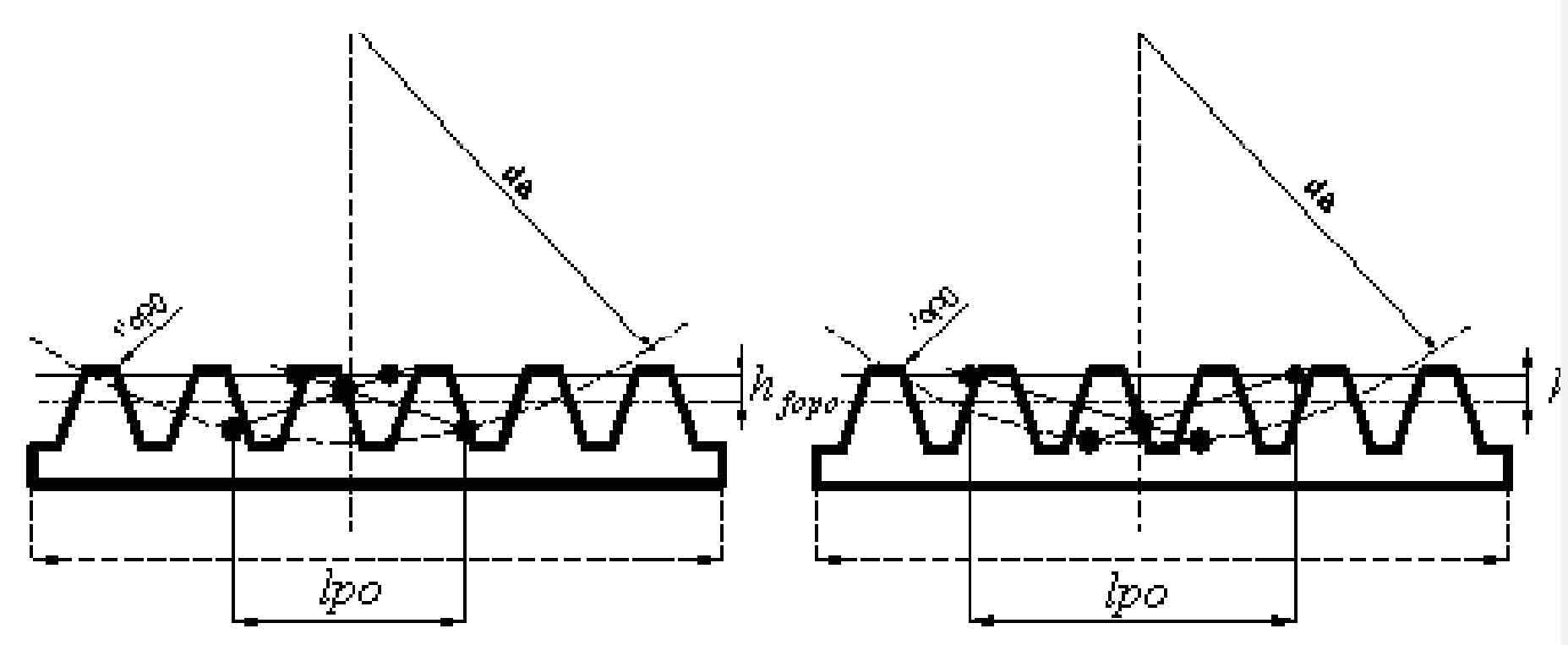

The calculation of the length of the generating area of the gear hobbing hob should consider the distance between the two ends of the two meshing lines at the tooth top of the gear hobbing hob and the distance between the two ends at the tooth root, as shown in Figure 2. The generation of gear tooth profile is generated in the tooth profile generation area. The tooth profile generation area is symmetrical with nodes. The size of the tooth profile generation area is calculated by the longer of the line length LPA between the end points of the two meshing lines and the intersection of the tooth top line of the gear hobbing hob and the line length LPF between the intersection of the two meshing lines and the gear top circle.