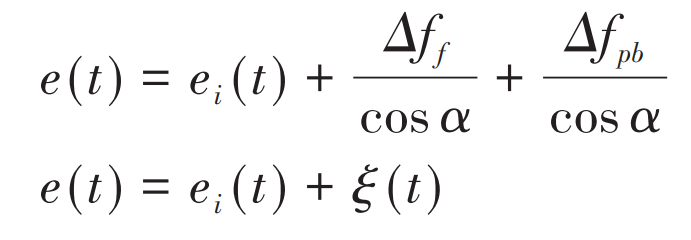

The error of spur gear mainly includes pitch error and tooth profile error. The pitch error and tooth profile error in each pair of spur gear pairs are synthesized into gear comprehensive transmission error. The deterministic theory and method make it change according to sinusoidal function in one meshing cycle.

Where EM is the constant value of meshing error of spur gear; EI is the amplitude of meshing error of spur gear pair along the direction of meshing line; ω Is the meshing frequency of spur gear pair; φ I is the initial phase.

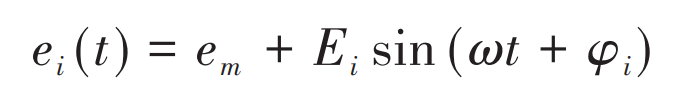

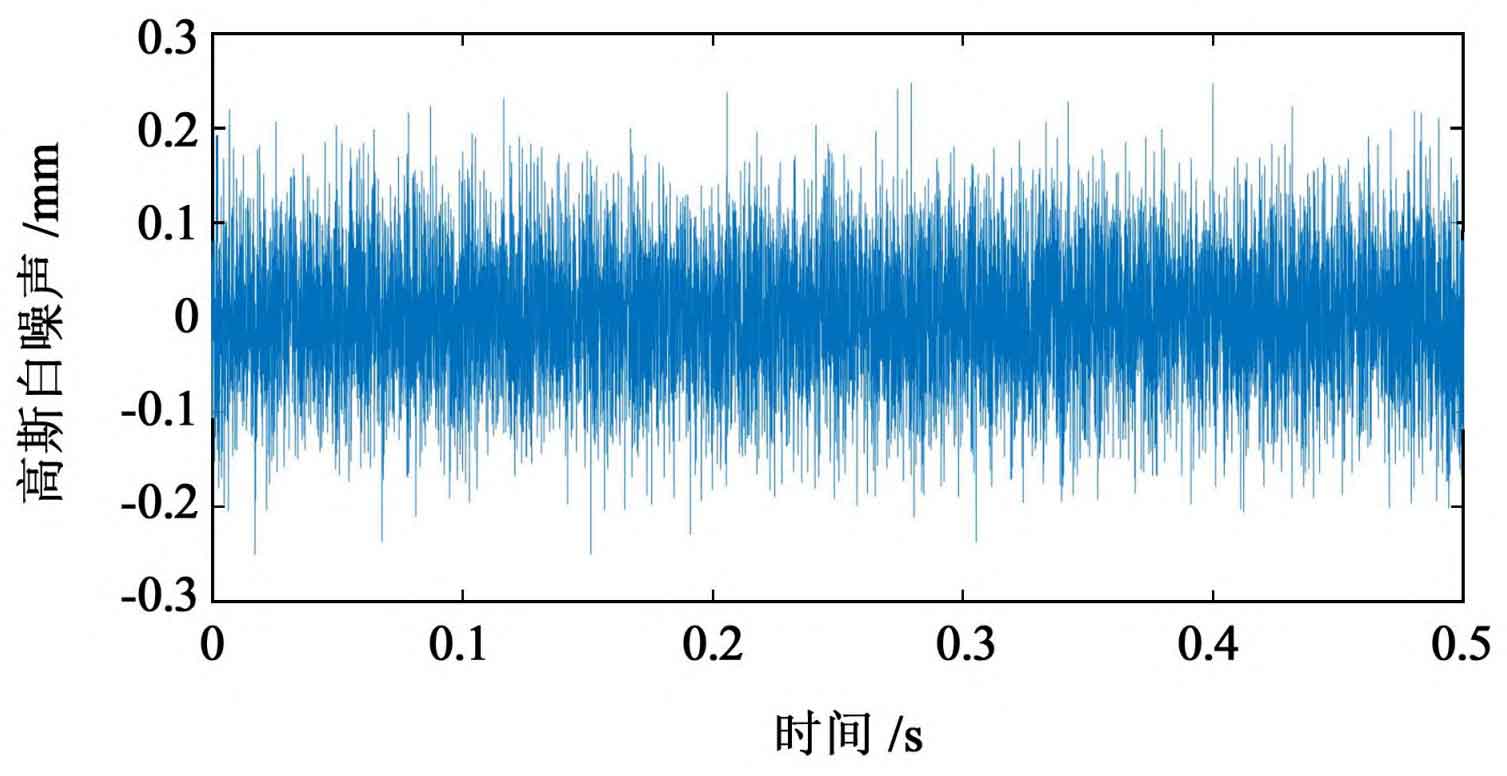

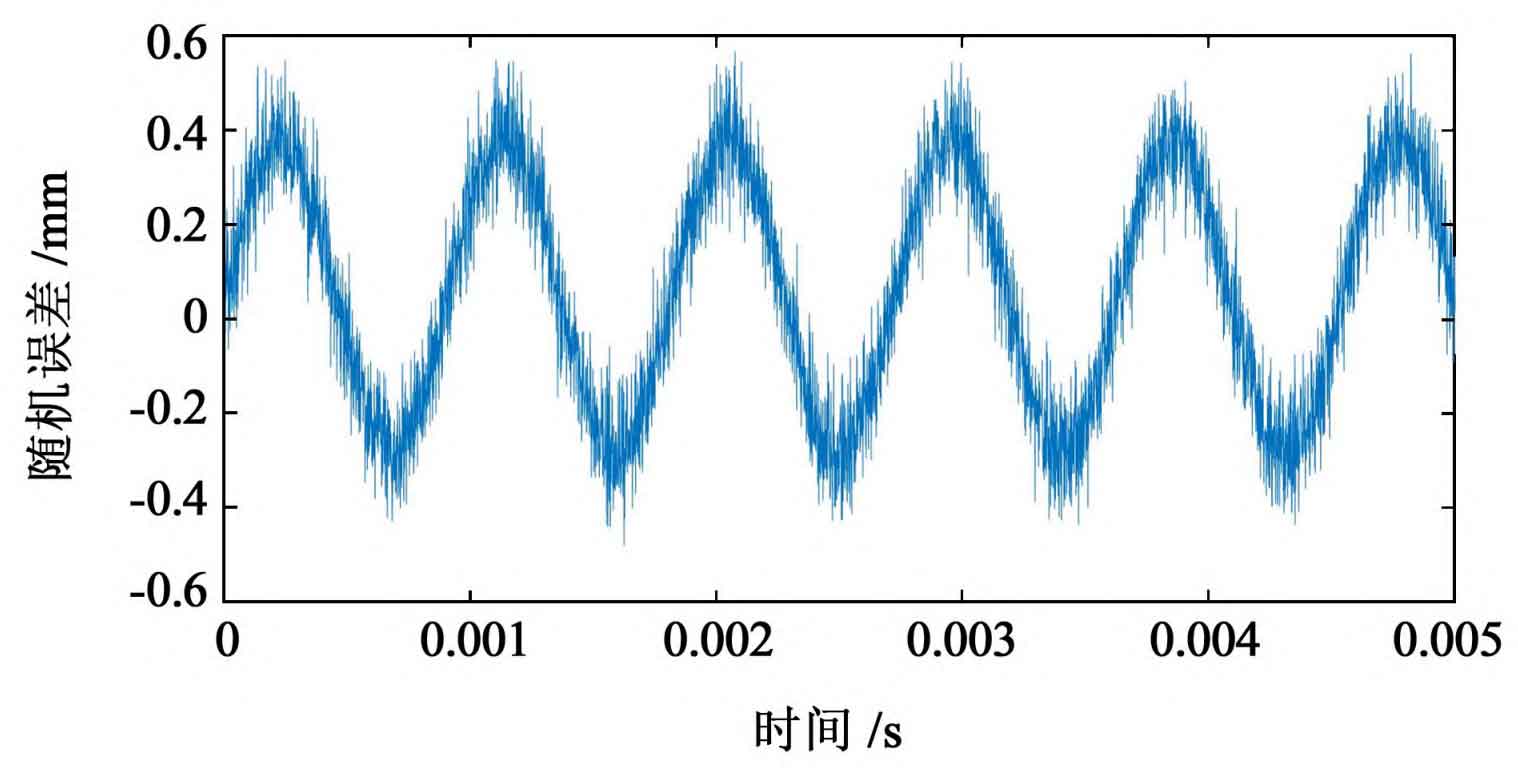

The tooth profile error and pitch error of spur gear are caused by processing conditions, which are independent of each other and change with time, as shown in the formula. Assuming that the tooth profile error and pitch error of spur gear are continuous random variables conforming to normal distribution within the tolerance range, the random error is superimposed by deterministic simple harmonic function and Gaussian white noise, as shown in the formula.

Where, Δ FF is the tooth profile error of spur gear; Δ FPB is the base node error; ξ (t) It is Gaussian white noise.

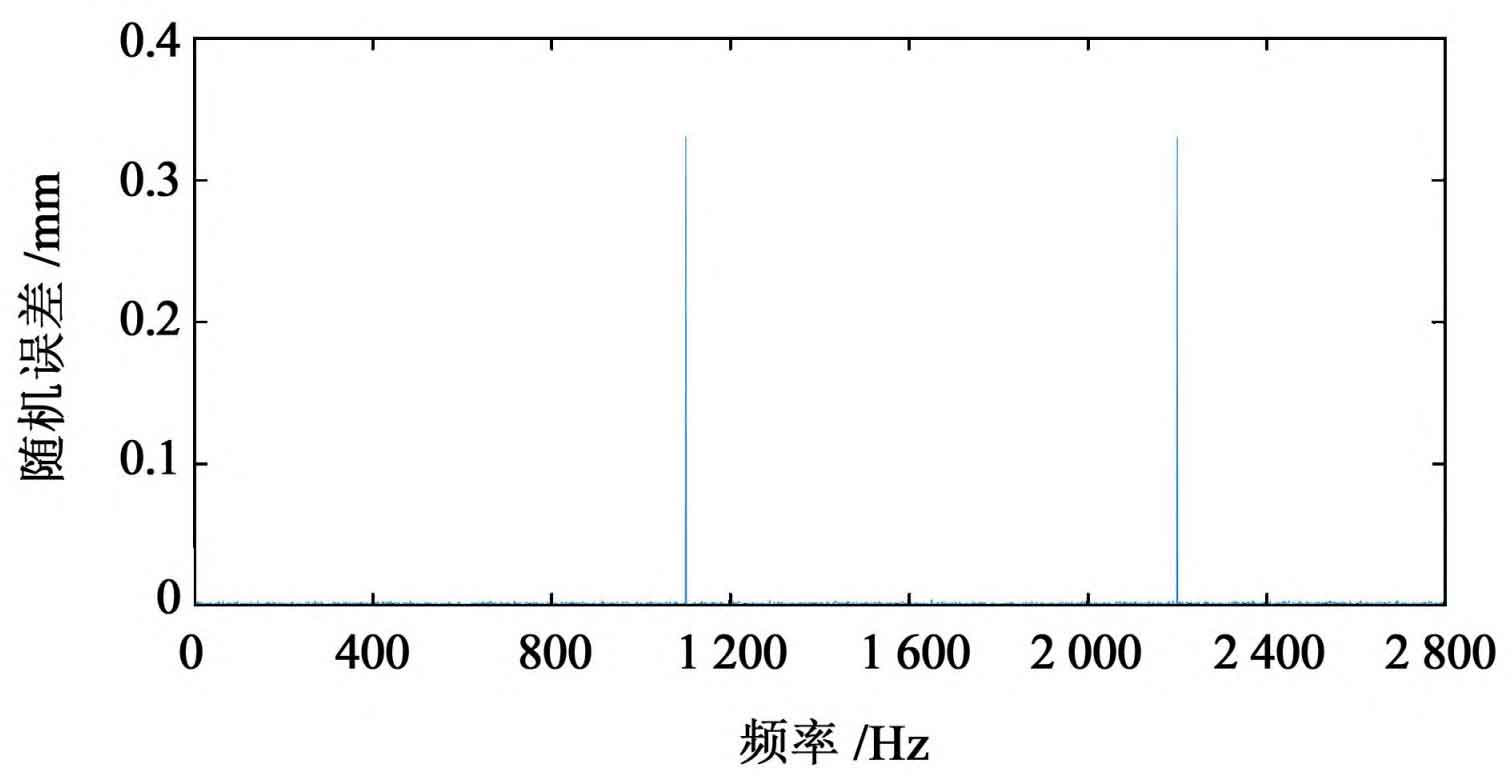

According to GB / T 10095 1-2008 and GB / T 10095 According to the standard 2-2008, the relevant parameters of grade 6 precision gear are selected as the deterministic part of random error, and the random variable obeys the mean value of 0 and the variance of 0 000 5, then the Gaussian white noise and the random error of level 6 precision spur gear are shown in Fig. 1 and Fig. 2.