Some parts need teeth as a benchmark. For example, the time difference is generated by controlling the angle of the spline relationship between the crankshaft and the crankshaft assembly. The relationship between the position of the hob and the axial direction of the hob must be maintained.

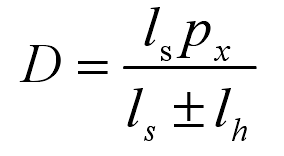

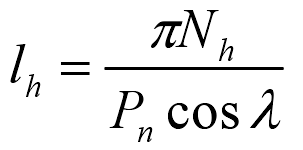

Since the hob is similar to a turbine in machining, the hob rotates on the central axis independently of the phase fitting. In order to compensate for the rotary cutting of this independent hob tooth, the tool channeling must be based on the diameter of the hob indexing circle and the tooth direction of the hob. Establishing a correct positional relationship between the part and the hob can ensure the continuous machining of the tool, which can be roughly calculated according to the following formula:

D = tool shifting amount of hob

LH = hob tooth direction

Ls = axial tooth direction angle coefficient of hob

λ = Hob tooth direction angle

If the rotation direction of hob and gear is the same, mark with minus sign; If the rotation direction of hob and gear is opposite, mark with a plus sign. After each tool shifting, the position of hob teeth is different, which will produce a new relationship between teeth and cogging. If there is no such condition, the hob teeth may be misaligned.