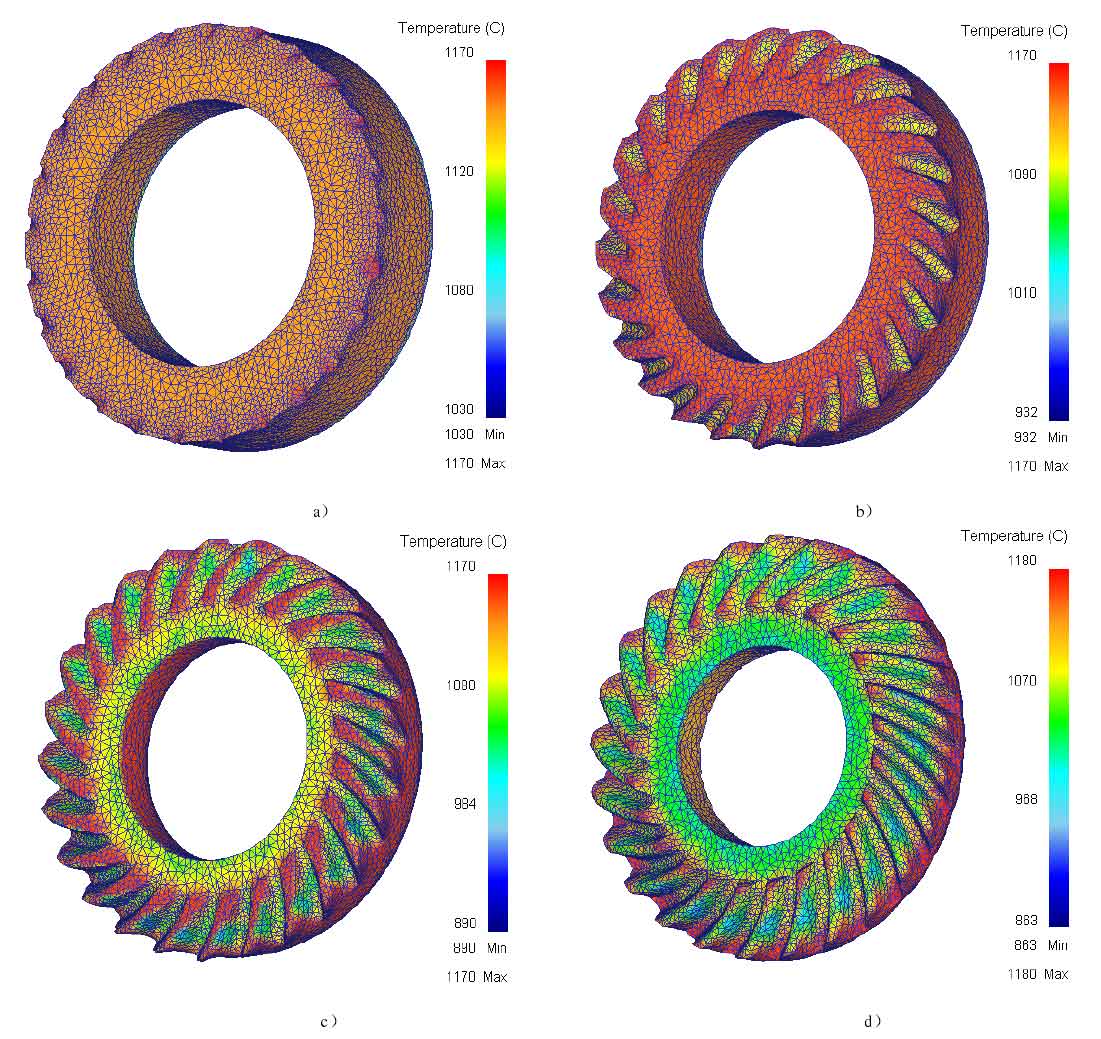

The forming temperature distribution of the bevel gear is reasonable, which has a great impact on the forming quality of the forging metal. As shown in the figure, the temperature field distribution of the upper die under different reduction is shown.

In the process of deformation, the change of temperature field is affected by two factors:

1) The plastic work produced by the blank metal during plastic deformation is absorbed by the blank in the form of heat because it is too late to convert into other forms of energy, resulting in the temperature rise of the metal blank of spiral bevel gear.

2) Due to the temperature difference between the blank and the die bore, there is heat exchange between the blank and the die bore and the surrounding environment in the forming process, resulting in the decrease of the temperature of the blank of spiral bevel gear.

From the above analysis, it can be seen that the contact time between the root part and the center part of the spiral bevel gear forging and the tooth die is long in the whole forming process, resulting in a decrease in the temperature. However, as for the spiral bevel gear forging as a whole, the temperature field is still relatively uniform, and the spiral bevel gear forging metal can obtain a good internal structure.