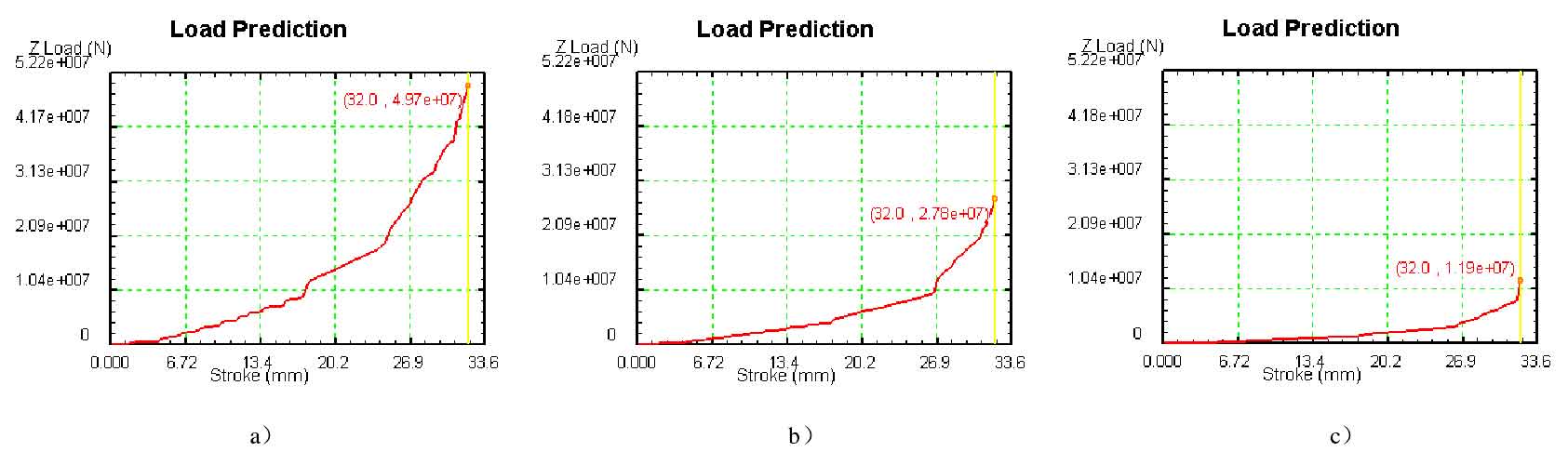

In order to investigate the influence of initial forging temperature on the precision forging of spiral bevel gear, the initial forging temperature is set as 20 ℃ (cold forging), 800 ℃ (warm forging) and 1150 ℃ (hot forging), the die temperature is set as 300 ℃ during hot forging and warm forging, and the die does not need to be preheated during cold forging, and other initial conditions remain unchanged. The three forming processes are simulated by DEFORM-3D, and the load stroke curve is obtained, as shown in the figure.

The simulation results show that the load at 1150 ℃ is 57% lower than that at 800 ℃ and 76% lower than that at 20 ℃. It can be seen that the forging deformation force of spiral bevel gear during precision forging decreases with the increase of initial forging temperature. The main reasons are as follows: with the increase of initial forging temperature, on the one hand, the kinetic energy of metal atoms increases and the slip resistance decreases; On the other hand, metal materials undergo dynamic recrystallization and dynamic recovery at high temperature, which reduces or even eliminates the work hardening effect. As a result, the flow stress of metal materials is reduced and the plasticity of metal is improved. Because the shape of spiral bevel gear is complex and difficult to form, the optimal initial forging temperature is 1150 ℃.