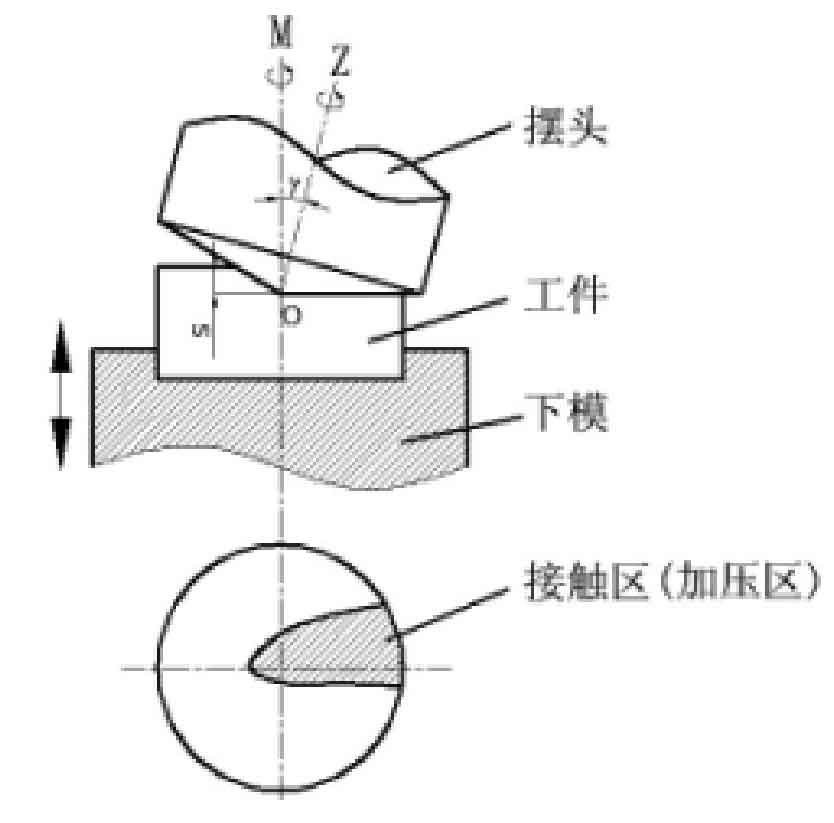

Swing rolling is a plastic forming method that rotates and swings on the bevel gear blank according to a certain motion path through an upper die with a cone, and gradually forms by bearing continuous local pressure. The working principle of swing rolling is shown in the figure.

The swing rolling die is divided into two parts. One part is the cone like cone, which is used as the active die. It is in local contact with the bevel gear blank in the forming process and applies pressure to it to play the active pressurization role; The other part is the die, that is, the part where the workpiece is installed, but this part has no relative movement with the workpiece.

Process flow: blanking → heating → thick pier → punching blind hole → punching connecting skin → reaming → rotary rolling shaping.

Swing rolling has many advantages over other forging methods:

- Small applied load. Because rotary forging is local pressure, the contact area between the die and the workpiece is only 1 / N of that of the conventional method, so the stress is reduced; Because the movement of the workpiece and the upper die of the cone belongs to rolling, the friction coefficient is small, and the resistance restricting the metal flow is also relatively reduced.

- The service life of the die is long. Because the load applied by the die to the workpiece is small, the bearing capacity of the die is small and intermittent, so the wear of the die is small and the service life of the die is long.

- Bevel gear forgings have high quality and precision. The bevel gear forging processed by rotary forging process can reach grade 7 quality accuracy, and the surface of bevel gear forging is smooth, and the surface roughness can reach Ra0 4-0.8um.

In addition, while it has many advantages, it also has some shortcomings:

- Rotary forging process is only applicable to axisymmetric parts, such as discs and rings.

- The lower die of the rotary forging die has only one die cavity. Only when the bevel gear forging rotates around the motion center of the upper die in this die cavity can the required workpiece shape be processed. At the same time, the conical upper die must also move around one center. Only when the two motion centers remain consistent can the smooth operation of the die be ensured.

- The rotary rolling die is more suitable for larger workpieces.