When the forming temperature distribution of the driven gear is different, the forming temperature distribution of the driven gear always changes greatly. The distribution and variation law of equivalent strain under different forging temperatures of spiral bevel gears are basically the same. When the upper die starts to move down, the part with large strain is mainly distributed at the tooth root of the blank. At this time, the contact part between the upper die and the blank is the tooth root of the forging. With the continuous downward movement of the upper die, the blank metal flows into the upper die cavity. At this time, the equal effect change at the tooth top of the spiral bevel gear gradually increases and even exceeds the equal effect change at the tooth root. Until the die is closed, the equal effect change at the tooth top reaches the maximum, while the equal effect change at the tooth root remains basically unchanged in the whole process.

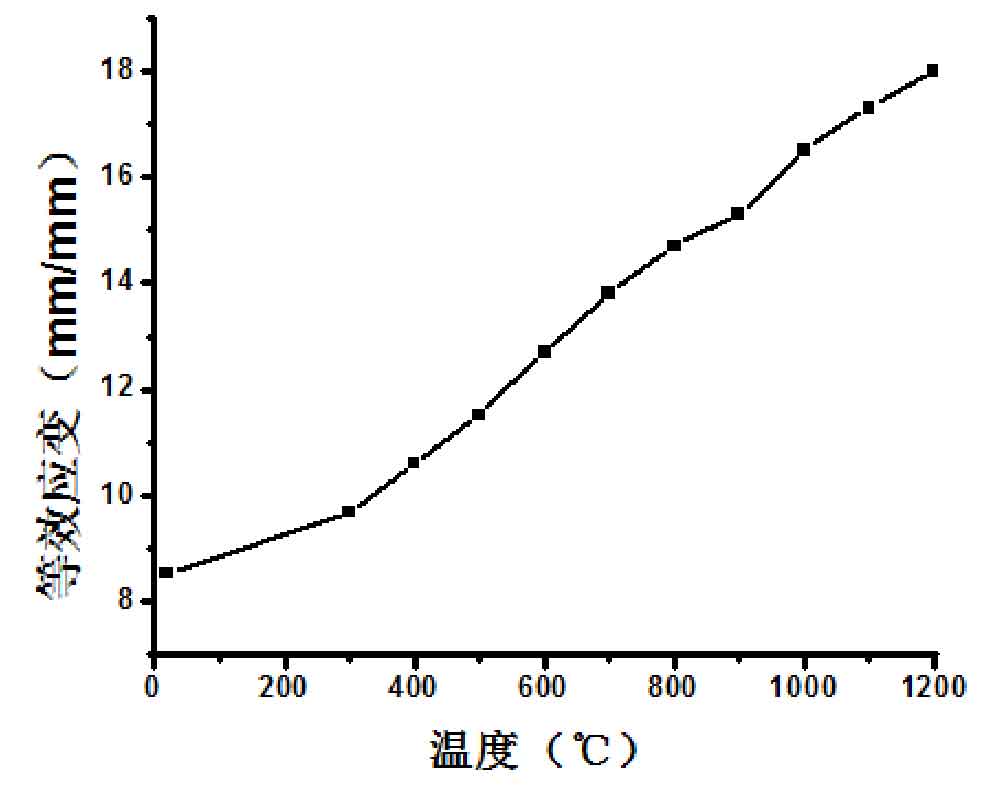

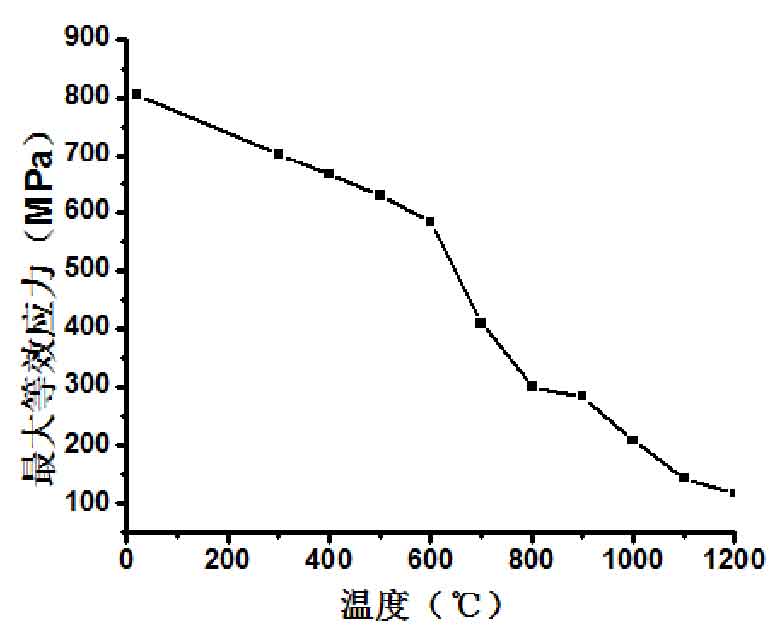

The maximum equivalent strain of spiral bevel gear under different temperatures is different. Figure 1 shows the relationship curve between the maximum equivalent strain and temperature. From Figure 1, it can be seen that there is a roughly positive correlation between the equivalent strain and temperature. With the increase of temperature, the equivalent strain increases gradually. At the same time, by analyzing Fig. 1 and Fig. 2, it can be seen that with the increase of temperature, the equivalent stress gradually decreases, while the equal effect change of spiral bevel gear gradually increases, which also reflects the negative correlation between the maximum equivalent stress and the maximum equal effect change.

Based on the above travel load analysis, equivalent stress analysis and equivalent strain analysis, it can be seen that the plasticity of metal increases with the increase of temperature, and the higher the temperature, the easier it is to form. From the relationship curve between maximum load and temperature and the relationship curve between maximum equivalent stress and temperature, it can be seen that when the temperature is between 600 ℃ and 800 ℃, the plasticity increases significantly with the increase of temperature, and its maximum load and maximum equivalent stress decrease significantly, The hot working temperature is too high, which requires a lot of energy. Moreover, due to the high temperature, it is easy to form oxide film on the surface of spiral bevel gear forgings. It also needs subsequent machining to remove the oxide film, resulting in material waste and affecting the quality of spiral bevel gear forgings. Therefore, the optimal scheme of forming temperature should be warm working, and the processing temperature is 800 ℃.