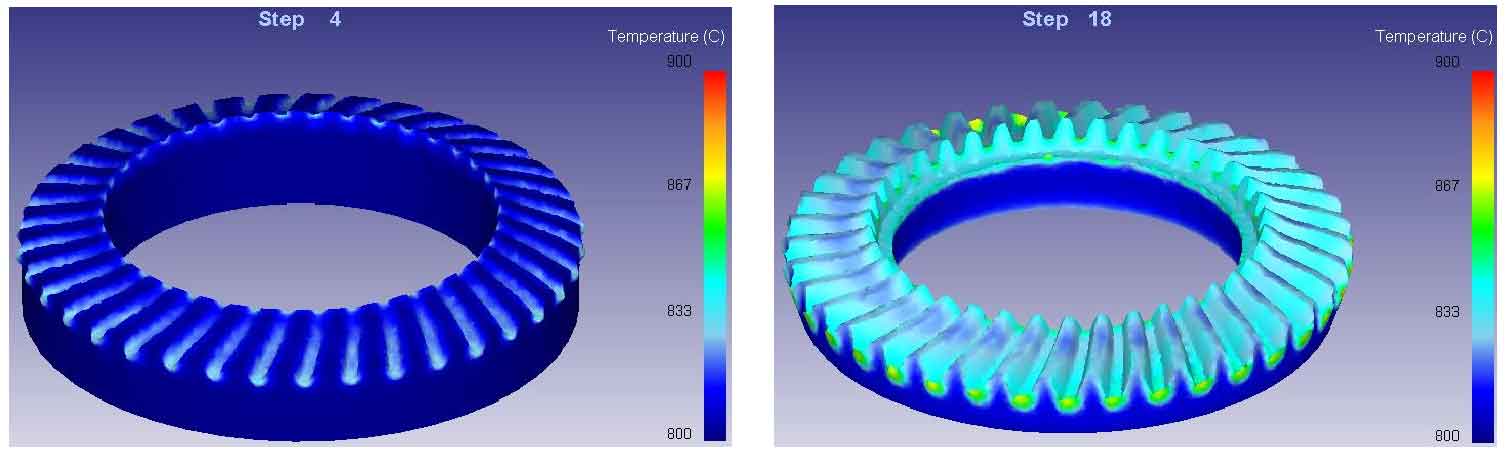

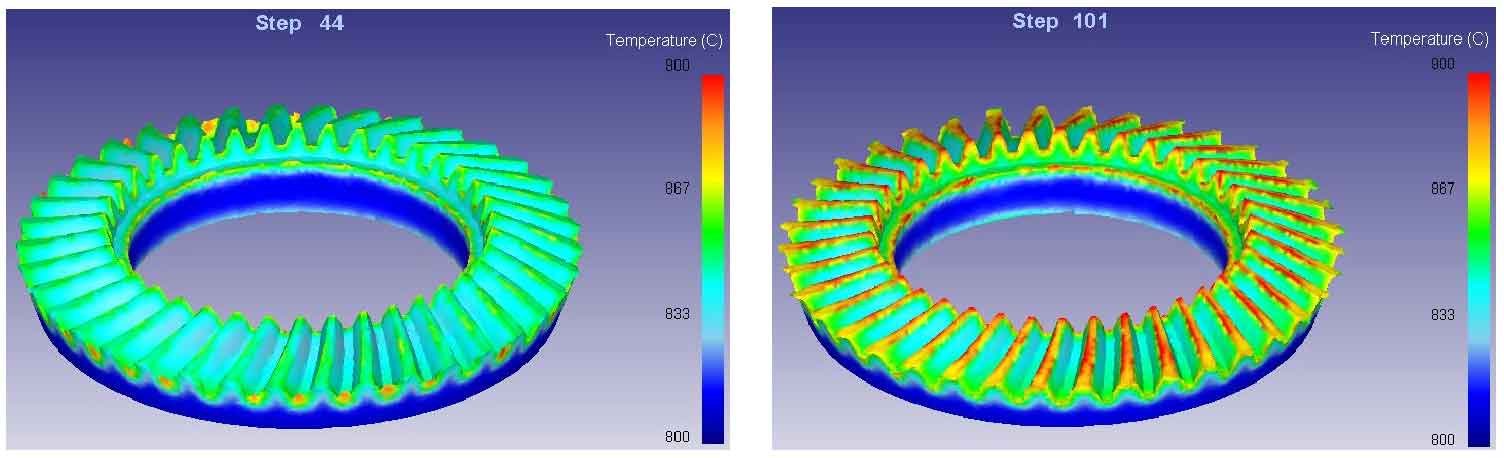

In the process of metal plastic forming, most of the deformation work of metal plastic deformation will be transformed into the internal energy of blank and die, which will increase the metal temperature of blank. Therefore, with the gradual increase of stroke, the temperature of blank will also increase. The figure shows the temperature distribution diagram of blank metal in different strokes during warm precision forging, in which figure (a) is the temperature distribution diagram when the stroke is 2.7 mm, figure (b) is the temperature distribution diagram when the stroke is 11 mm, figure (c) is the temperature distribution diagram when the stroke is 12.3 mm, and figure (d) is the temperature distribution diagram of the final step. It can be seen from the figure that the metal temperature of the tooth part of the gear changes obviously. With the increase of the stroke, the metal temperature of the tooth part gradually increases, while the metal temperature of the lower part of the gear remains basically unchanged, that is, the metal temperature in the large deformation area increases obviously, while the metal temperature in the small deformation area is relatively stable. The reason for this phenomenon is that the deformation in the large deformation area is large, resulting in more deformation work and larger temperature change. The main deformation from figure (a) to figure (b) is upsetting deformation. The deformation work produced in this process is small, so the temperature increases slightly; The process from figure (b) to figure (c) is the forming process of tooth profile. This process is mainly that the blank metal flows into and fills the upper die cavity, so the deformation work is small, so the temperature rise is not obvious; The process from figure (c) to figure (d) is the process of forming flash. At this time, the metal has filled the cavity, the deformation resistance in the forming process is relatively large, the friction between the blank and the die is also relatively large, and the deformation work is relatively large. Therefore, the blank temperature increases rapidly and finally reaches the maximum value, about 900 ℃.

As can be seen from figure (d) in the figure, the part with higher temperature is mainly concentrated on the upper surface of the tooth top, so the blank and die of this part are prone to thermal fatigue and defects, and oxidation is easy to occur due to high temperature. The main heat source of the tooth top part is the heat generated by friction with the upper die. The use of lubricant can not only reduce the heat generated by the deformation work of this part, but also help isolate the air and prevent the oxidation of the blank metal to form an oxide layer. Therefore, the use of lubricant plays an important role in the quality of forgings produced by the precision forging process of driven spiral bevel gear of automobile rear axle, The lubricant selected in this paper is water graphite to lubricate the blank and die.