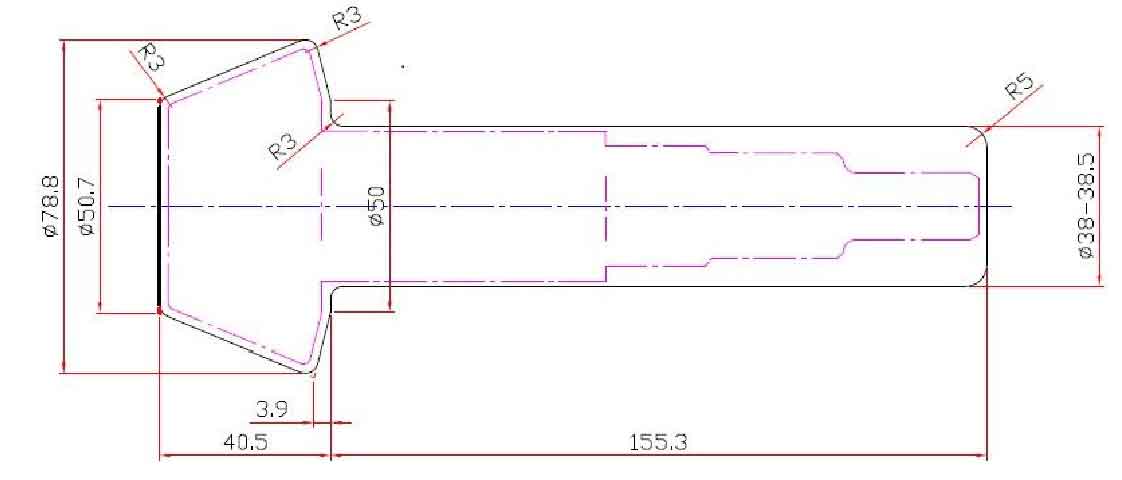

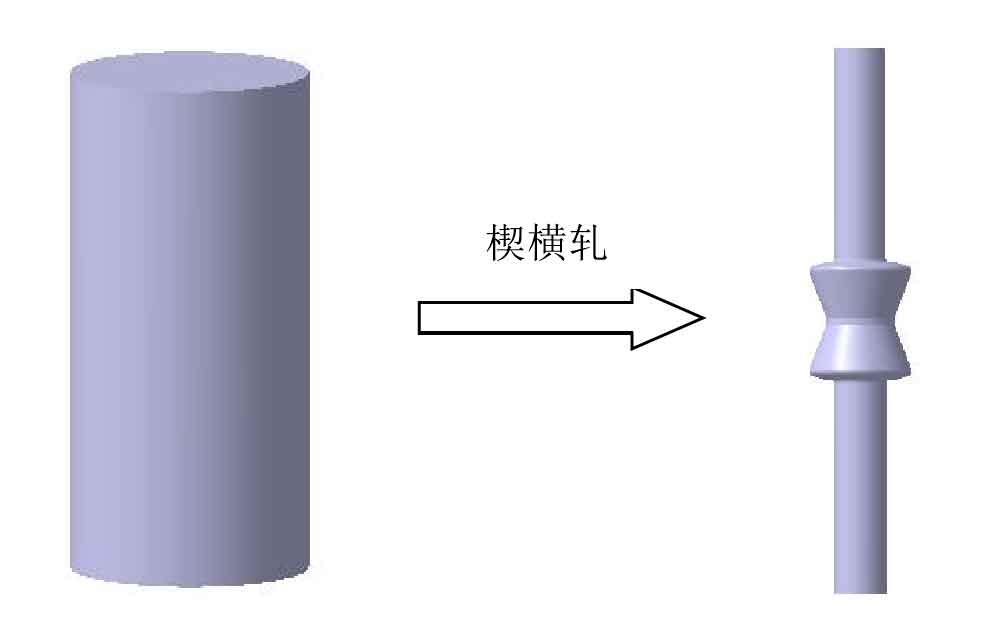

This process is planned to adopt one-time rolling forming. Considering the requirements of cross wedge rolling process on the symmetry of binding parts, two driving spiral bevel gear blanks can be rolled symmetrically at one time. This process focuses on the part of the forming cone head and the connection part between the forming cone head and the shaft. For the step shaft forming of the shaft, the process has been relatively mature and is not the research object of this process. Therefore, the blank shown in Figure 1 is not modified to save simulation time. The specific process is shown in Figure 2.

This process only needs one process of cross wedge rolling to form the billet of driving spiral bevel gear. The key of this process is the design of cross wedge rolling roll and the formulation of rolling parameters. The spiral bevel gear blank studied in this paper belongs to shaft parts. The difference between the maximum cross-sectional diameter and the minimum cross-sectional diameter is 40mm, and the cross-section changes greatly and irregularly. In order to ensure the stability of the rolling process, the guide plate mechanism is essential, and the specific parameters and placement methods of the guide plate are strictly limited. Tools required for research: CATIA, deform, outcad, origin, etc. Mainly through CATIA modeling, deform finite element simulation analysis to complete the research content of this chapter.