The machining method of gear shaft tooth profile with modulus of 65mm is not exactly the same as that of profiling method. It is a special form of profiling method for machining gear tooth profile. If the overall tooth profile template and the overall finger milling cutter are designed according to the processing method of gear shaft tooth profile with module of 50mm, then the milling cutter is processed according to the tooth profile template. The maximum diameter of the processed milling cutter is 190mm, the length is 170mm, and the mass exceeds 30kg. Such a tool cannot be used on the existing boring and milling machine.

According to the working environment and application requirements of the part, the transmission speed of the gear shaft with modulus of 65mm is low and the machining accuracy is not high. Therefore, according to the working condition of the gear shaft, change the traditional processing method, design the integral tool into a component form, design two split finger milling cutters, and use these two split finger milling cutters to jointly complete the processing of one tooth profile, that is, each milling cutter only completes a part of one tooth profile. In this way, not only the volume and mass of each cutter are reduced to 1 / 4 of the overall milling cutter, the connection rigidity of the milling cutter, the cutter base and the spindle is improved, but also the contact length of the cutter edge is reduced by half, which can effectively solve the problem of insufficient power and connection rigidity of the machine tool. The specific methods are as follows.

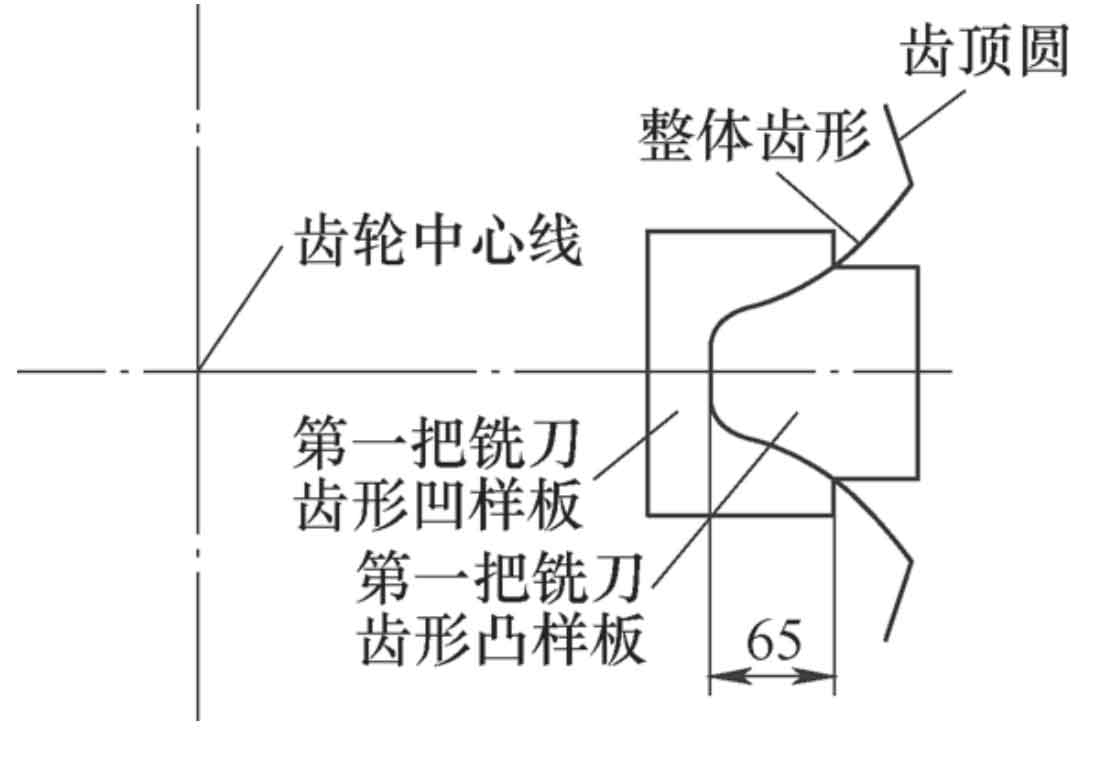

1. Tooth profile design of the first milling cutter

Firstly, the coordinate points of the tooth profile are calculated according to the marked parameters of the drawing, and the complete tooth profile is drawn by using computer software (such as CAXA, AutoCAD, etc.); Then, cut a part of the complete tooth profile, that is, cut more than half of the part from the root as the convex template of the tooth profile of the first milling cutter. For example, if the full tooth height is 117mm, the cut length is 65mm; Finally, according to the convex template of tooth profile, the concave template of tooth profile is made. In this way, the tooth concave template can be used as the tooth template of the first finger milling cutter. As shown in Figure 1.

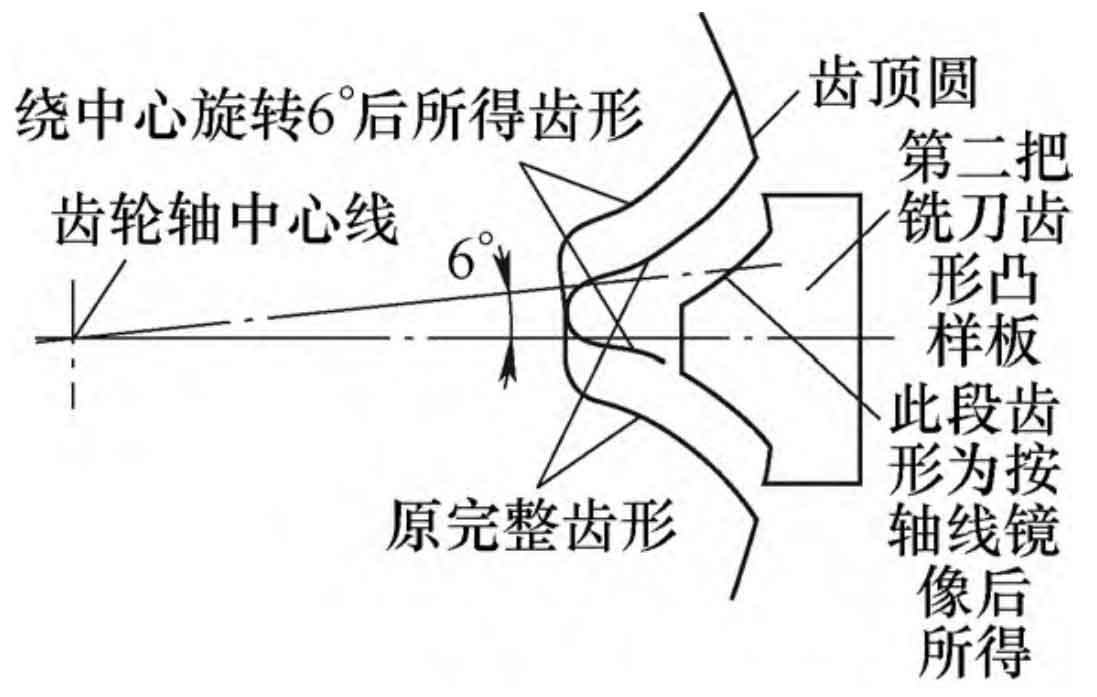

2. Tooth profile design of the second milling cutter

The design of the tooth profile template of the second milling cutter is the key to the whole involute tooth profile processing, because the accuracy of the tooth profile template of the second milling cutter will directly affect the correctness of the processed involute tooth profile. The design principle is to use computer software to simulate the actual tooth milling processing, and generate the tooth profile template of the second milling cutter according to the actual rotation angle of the gear shaft. The specific methods are as follows.

Firstly, rotate the complete tooth profile drawn by the computer software with the center point O of the gear shaft as the origin for 6 °, and the center line does not rotate, so as to obtain the figure of asymmetric tooth profile on both sides of the center line. One side is close to the center line and the other side is far away from the center line; Then use the computer drawing software to copy the tooth profile on one side close to the center line with the center line o a as the axis to obtain the tooth profile on the other side; Finally, cut the remaining tooth profile after the full tooth height of 117mm minus 65mm, which can be used as the tooth profile convex template of the second milling cutter. As shown in Figure 2.

The tooth concave template is made according to the tooth convex template designed above, and the finger milling cutter can be processed and manufactured by using the tooth concave template.