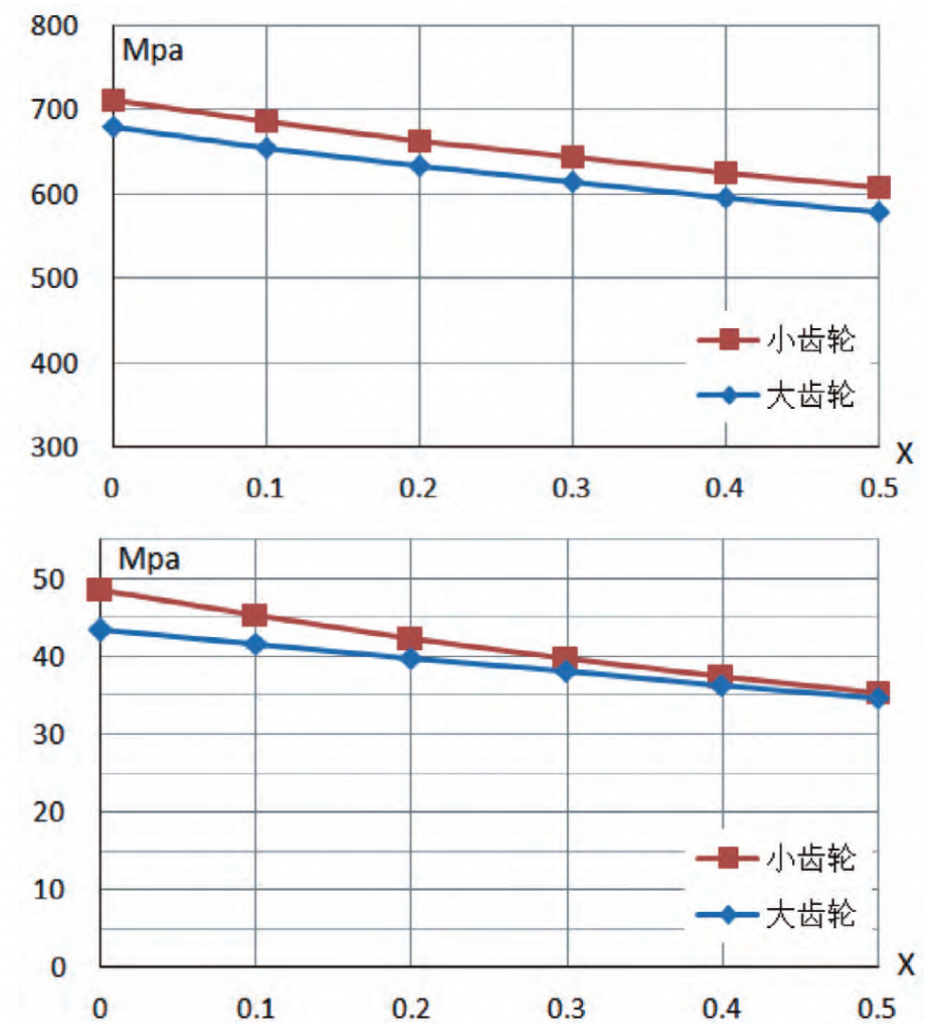

In order to study the influence of different modification coefficients on the strength of cylindrical gears, a group of cylindrical gear parameters are selected, as shown in the table. The three-dimensional models of cylindrical gear pairs are established according to different displacement coefficients, and then analyzed according to the methods discussed above. The tooth surface contact stress and tooth root bending stress corresponding to different displacement coefficients can be obtained, and the curve is shown in the figure.

The analysis results show that under the same load conditions, with the increase of displacement coefficient in a certain range, the tooth surface contact stress and tooth root bending stress are reduced, which shows that the positive displacement cylindrical gear does improve the bearing capacity. However, it should be noted that the displacement will lead to the reduction of tooth top thickness and other problems. The larger the displacement coefficient is, the better. It should be comprehensively analyzed according to the specific situation to determine the reasonable displacement coefficient.

| Parameters | Number of teeth Z | Tooth width B | Displacement coefficient x | Modulus m | Torque M |

| pinion | 20 | 10 | 0/0.1/0.2/0.3/0.4/0.5 | 10 | 500Nm |

| wheel | 30 | 10 | 0/0.1/0.2/0.3/0.4/0.5 | 10 | 500Nm |