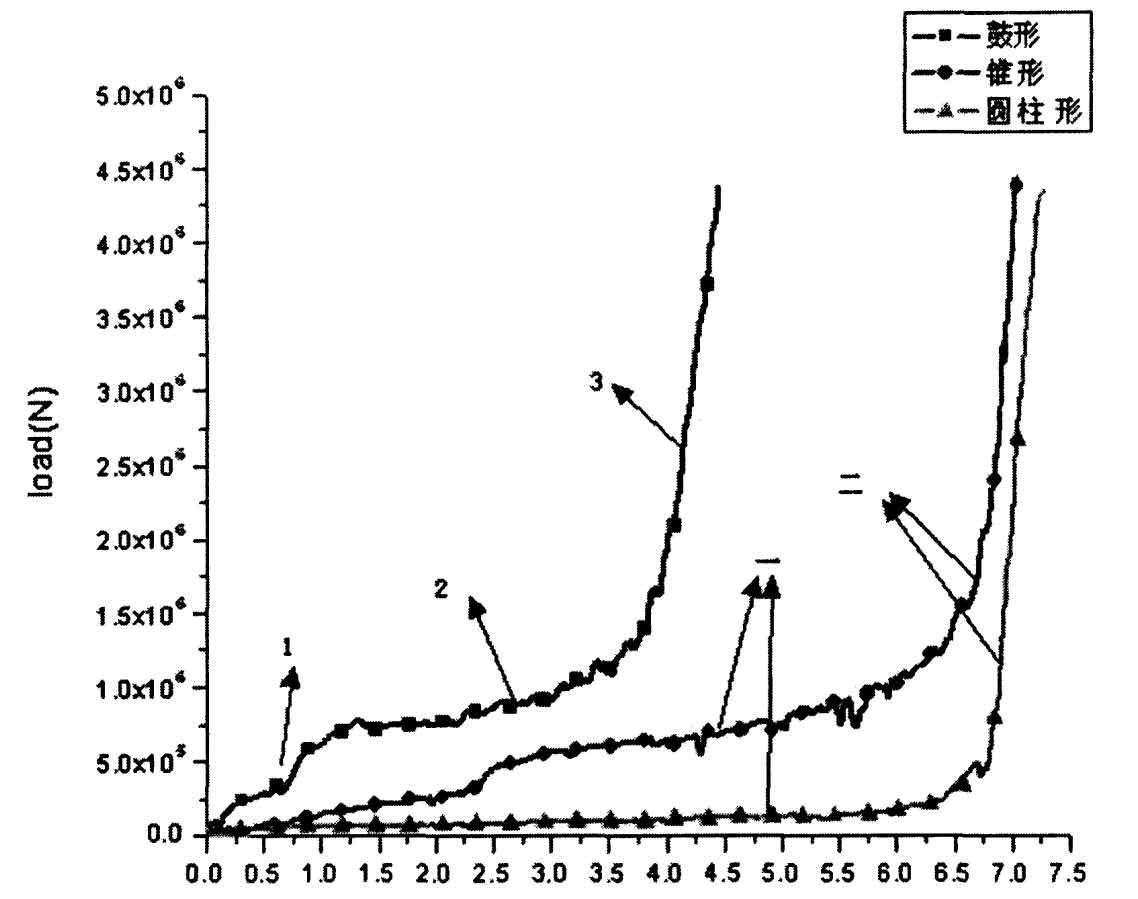

The forming load time curve of straight bevel gear blanks with different shapes is shown in the figure. From the forming load time curve, the trend of the three curves is basically the same, but their specific contents are very different. Firstly, from the line segment, for the drum blank of spur bevel gear, the process can be roughly divided into three stages. For the conical and cylindrical blanks of spur bevel gears, the process can be roughly divided into two stages.

At the beginning, the contact between the bottom of the spur bevel gear blank and the lower die is free upsetting, and the forming load rises rapidly; In the second stage, the side wall of spur bevel gear blank contacts with the lower die wall in a large area, the tooth shape is gradually formed, the load increases slowly, and the curve rises gently; In the third stage, most of the straight bevel gear tooth profiles are formed. In this stage, it is mainly the filling of the tooth corners, the load increases sharply and the curve rises sharply.

From the above analysis, it can be seen that the conical and cylindrical blanks of spur bevel gear show one process stage in the free pier rough stage and the flash stage of filling, while the drum blank shows two independent stages. This is because at the beginning, the contour line of the drum blank has more contact with the lower mold cavity and the height is small. Therefore, the rough time of the free pier is short and the forming load rises rapidly, which can be clearly seen from the curve. Due to the large height of conical and cylindrical piers, the free pier has a long rough time, and the transition between the first stage and the second stage is relatively gentle, which can not be distinguished from the curve. The straight bevel gear drum blank has short free pier rough stage time and long time of adhering to the mold wall and filling stage, resulting in up and down deformation and uniform filling, so as to obtain the fully filled tooth shape. While the straight bevel gear conical blank and cylindrical blank have long free pier rough time and great difference in filling time along the whole tooth length. The filling in the middle of the tooth shape is the latest, which eventually leads to the local “meat shortage” defect in the middle.