The forming effect analysis is mainly used to analyze whether the equal height spiral bevel gear forging is completely filled, folded and the generation of external flash at the end of forging. The internal and external diameter of the equal height spiral bevel gear blank has a great impact on whether the blank is completely filled. Therefore, after a series of pre simulation tests, the outer diameter is 445mm, The blank of equal height spiral bevel gear with inner diameter of 325mm can fill the die cavity at the end of forging; The existence of blank cone angle of equal height spiral bevel gear makes the inner and outer sides of the blank contact with the die tooth shape at the same time, which eliminates the possibility of folding at the end of forging. Therefore, the forming effect analysis mainly analyzes whether there is external flash in the equal height spiral bevel gear forging after forging.

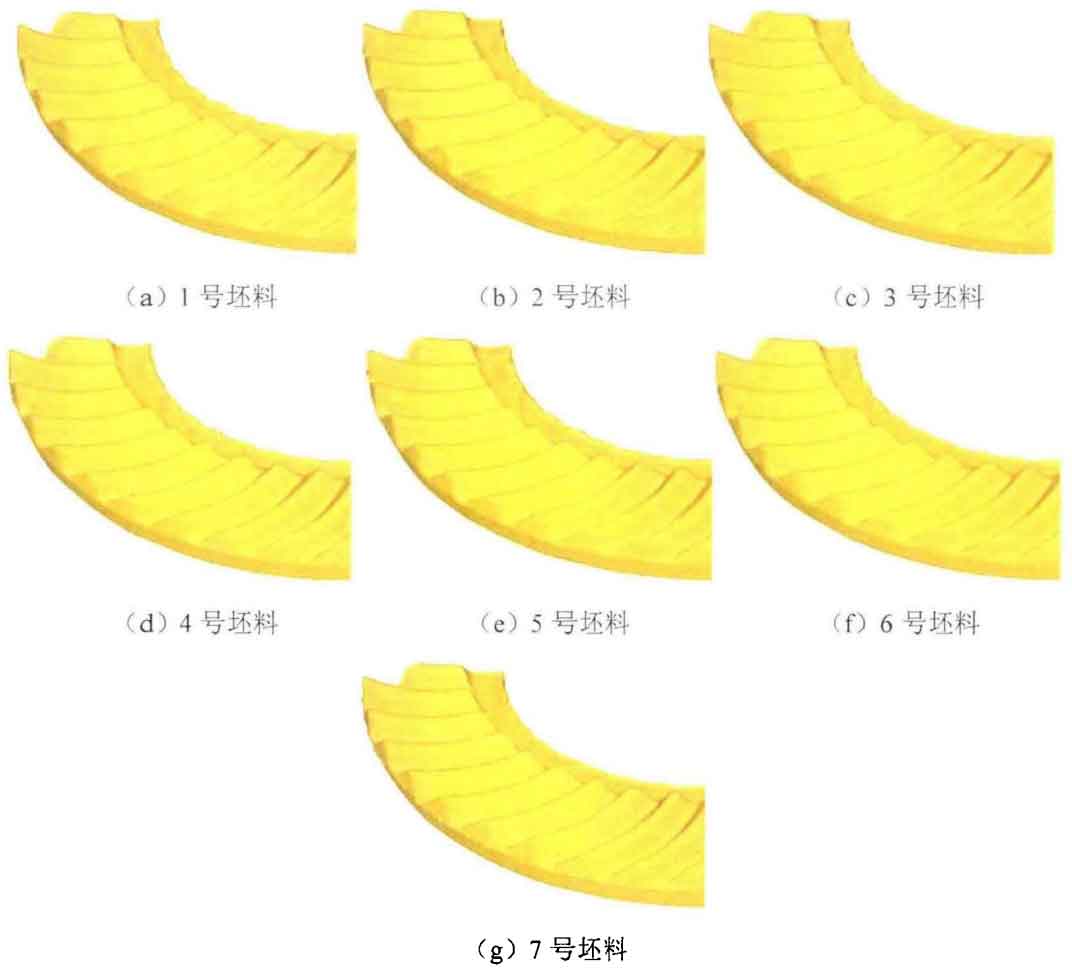

Figure (a) – (f) is the forming diagram of 6 groups of special-shaped section equal high tooth spiral bevel gear blanks, and figure (g) is the forming diagram of rectangular section blanks. It can be seen from the figure that under the condition of appropriate parameter regulation, the equal height spiral bevel gear forging can not produce external flash, which proves the feasibility of blank section design.