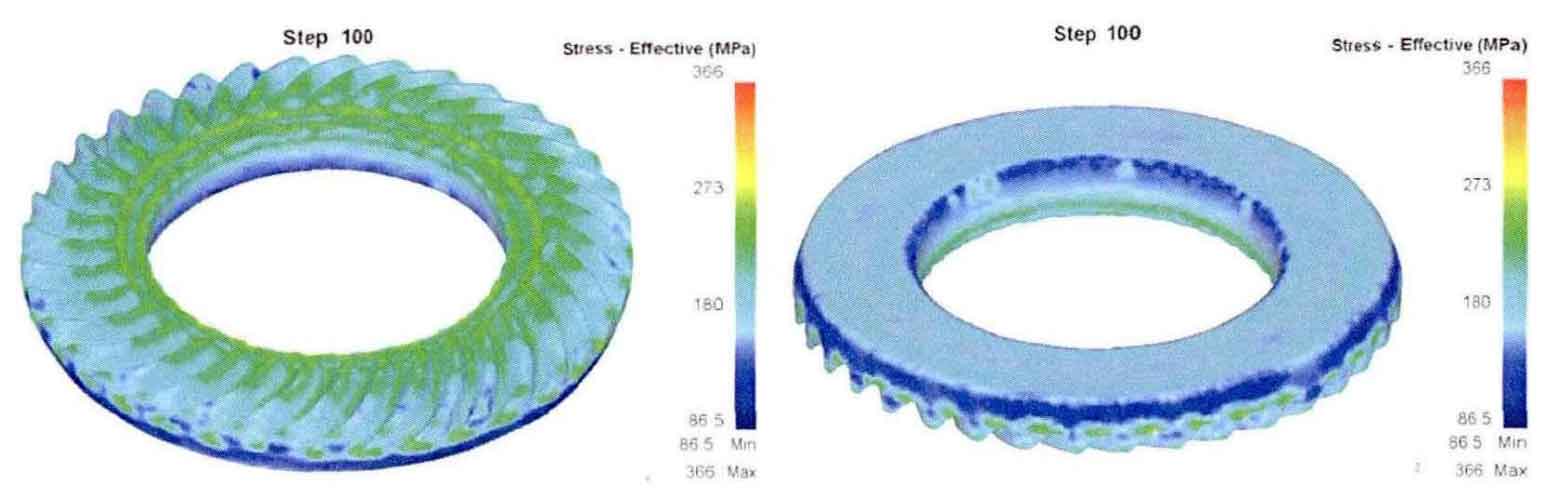

The equivalent stress in the forging process of equal height spiral bevel gear is an important analysis index, which affects the deformation of the whole die and tooth profile and the accuracy of equal height spiral bevel gear forging. Firstly, taking the blank as an example, the equivalent stress at the completion of forging is analyzed. Figure 1 is the cloud diagram of equivalent stress distribution of equal height spiral bevel gear forgings when the forging simulation is completed. It can be seen that the positions with large equivalent stress are mainly located at the root of large end tooth, the root of small end tooth and the position of inner flash, and the equivalent stress at other positions is relatively small; The overall situation of the equivalent stress on the tooth profile of equal height spiral bevel gear is from the big end to the small end, and the equivalent stress gradually increases, but there are also local fluctuations of the equivalent stress.

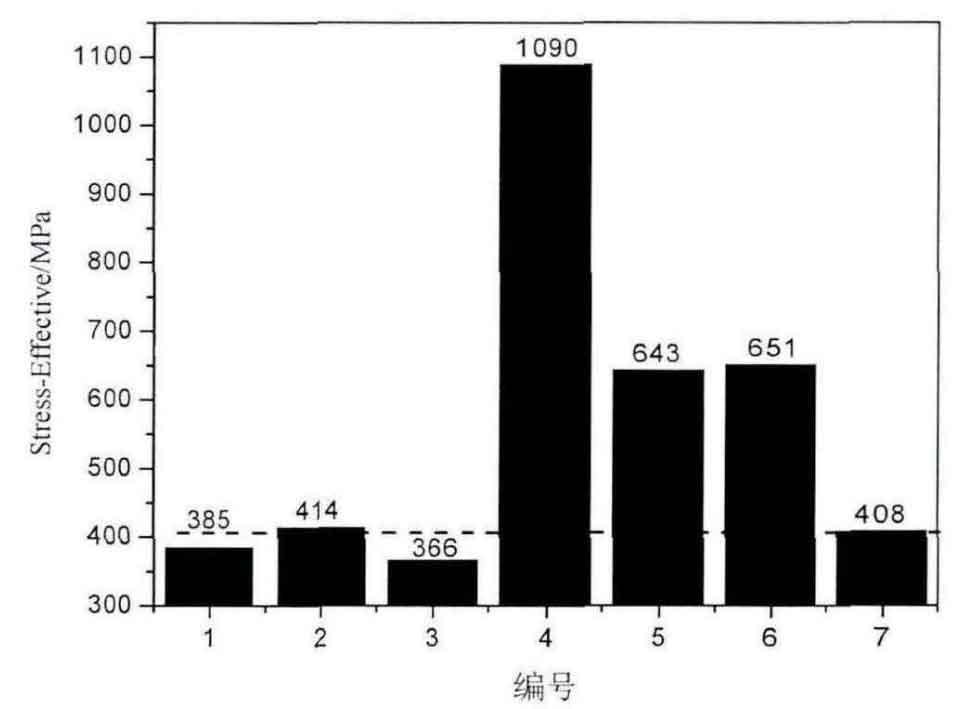

In order to better compare the equivalent stress of equal height spiral bevel gear blank with special-shaped section and equal height spiral bevel gear blank with rectangular section, the maximum equivalent stress of 7 groups of equal height spiral bevel gear blank at the end of forging is extracted respectively, and the drawing is made in origin based on the maximum equivalent stress of equal height spiral bevel gear blank with rectangular section, Get Figure 2.

It can be seen from the figure that the maximum equivalent stress of No. 1-3 equal height spiral bevel gear blank at the end of forging is less than or slightly higher than that of rectangular section blank, while No. 4-6 equal height spiral bevel gear blank will produce stress concentration during forging, and the maximum equivalent stress of equal height spiral bevel gear forging is much higher than that of rectangular section blank.