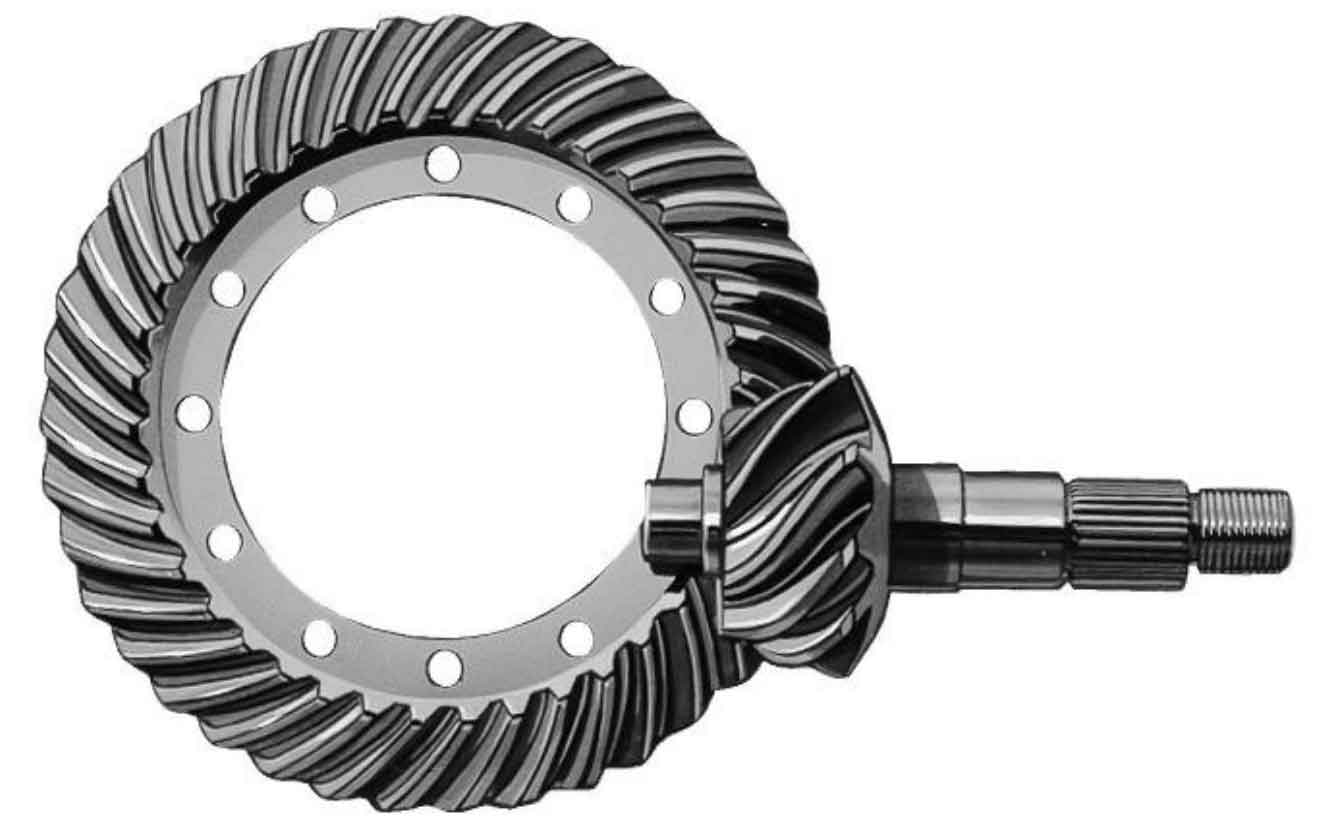

The main program of hypoid gear parametric design system is realized through several design units: input of design parameters and initial calculation, calculation of geometric parameters, strength design, application program and Pro / E2 0 software links, etc.

Visual C + + 6.0 for Pro / E2 0 to establish the main interface of hypoid gear parametric design system. In the main interface, under the hypoid gear design menu, input the design required parameters for preliminary calculation of parameters. After determining the initial value of parameters, calculate the geometric parameters to obtain the specific parameters of three-dimensional modeling of large and small bevel gears of hypoid gear pair and store them in the access database.

The formation of tooth profile of hypoid gear is studied, and the mathematical equation of spherical involute is deduced from the formation principle of spherical involute. Based on the spherical involute equation, in Pro / E2 0 software uses the function of generating curve from equation to generate spherical involute to complete the tooth profile of single tooth of hypoid gear pair. The mathematical model is established according to the new geometric algorithm. Based on the calculated geometric parameters, Pro / E2 0 software to establish the three-dimensional model of large and small gears of hypoid gear pair. In the process of model establishment, add parameters and relationships to drive the size of the whole model. Various secondary development methods of Pro / E software are studied, and the interface between VC + + 6.0 and Pro / E software is solved. Using Visual C + + 6.0 integrated development environment to Pro / E2 The Pro / Toolkit module in 0 software is used as the interface for secondary development to complete the establishment of hypoid gear parametric design system.