The purpose of designing the bevel gear pre forging is to ensure that the metal can fill the final forging cavity smoothly during the final forging, and to avoid the case that the gear teeth are not fully filled. Therefore, the general design principle of bevel gear pre forging is to make it as close to the shape of the final forging as possible through volume distribution, so that the die cavity can be filled with small deformation during the final forging process. In addition, when designing the pre forging, it should also ensure that the size of the bevel gear pre forging in the height direction is generally larger than the corresponding size of the final forging, so that the metal flow during the final forging is mainly rough. In order to reduce the forming load, the diffluence zone is designed at the difficult forming part.

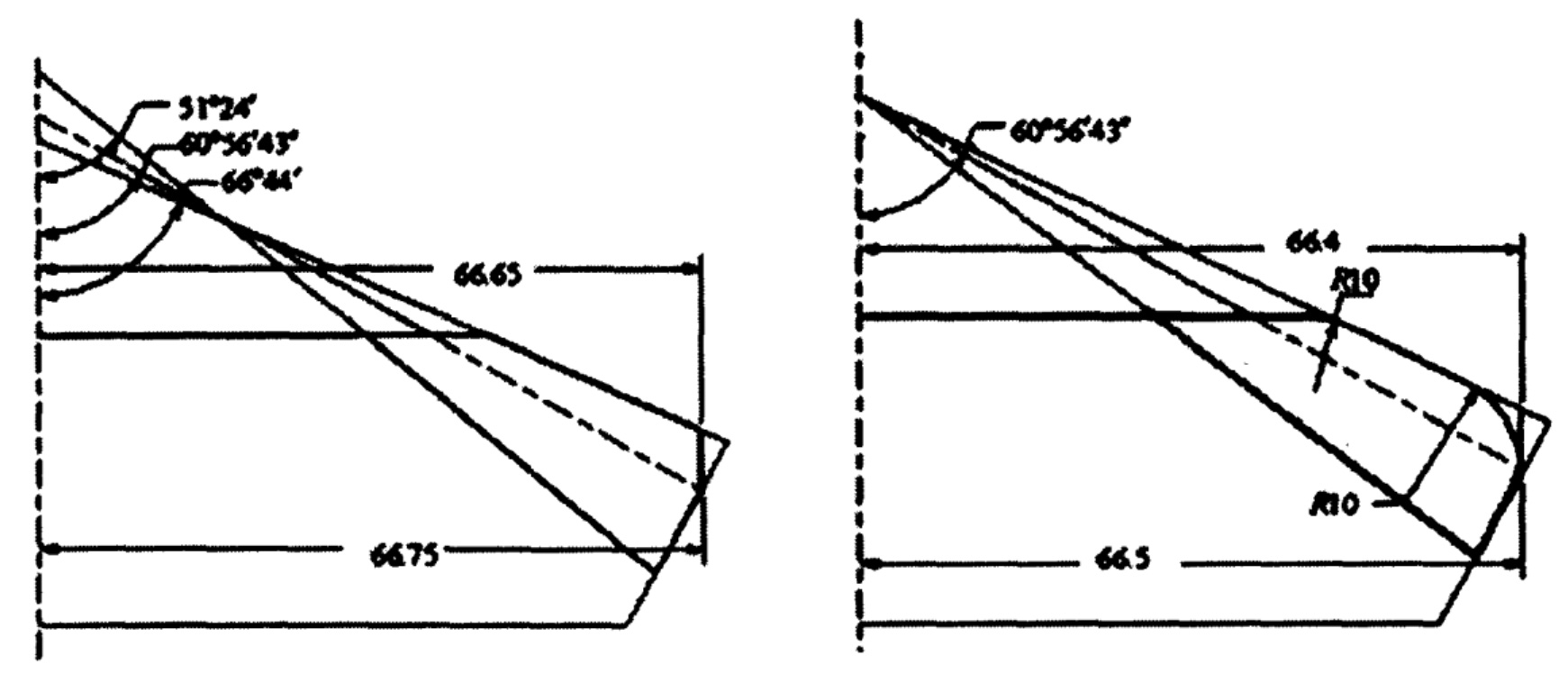

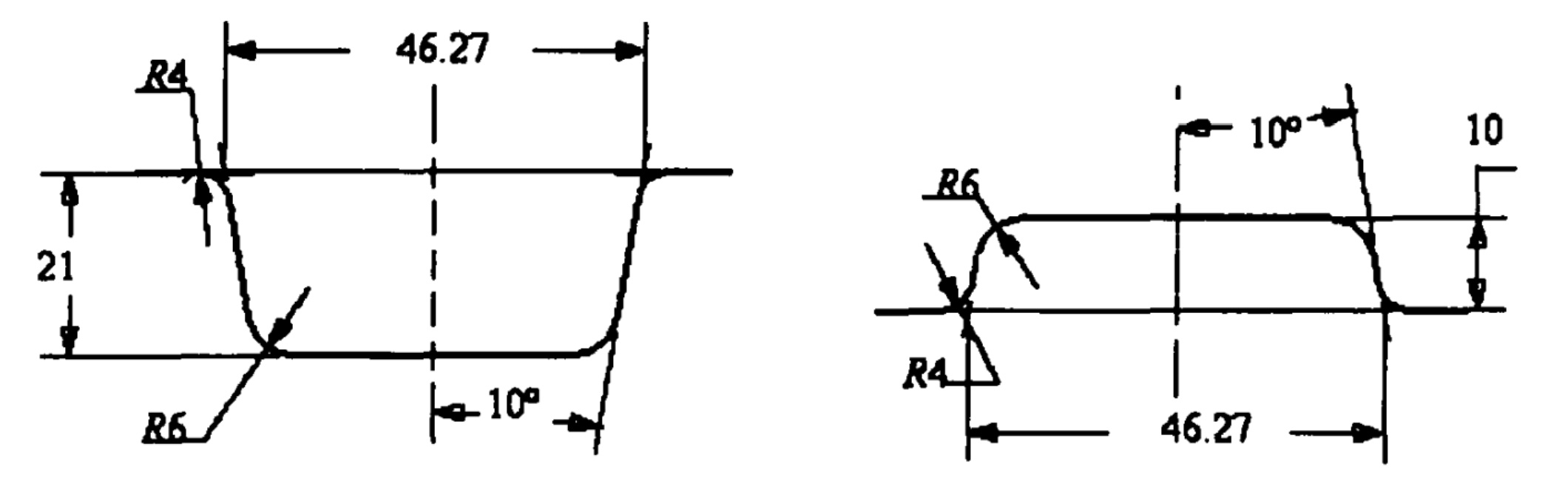

In view of the above principles, in the design of bevel gear pre forgings, in addition to reserving a certain precision forging allowance in the height direction, the blind hole size and tooth shape of pre forgings are also improved. Fig. 1 shows the pre forging of planet gear and half shaft gear Fig. 2, and Fig. 3 shows the blind hole dimension parameters of pre forging of planet gear and half shaft gear respectively.

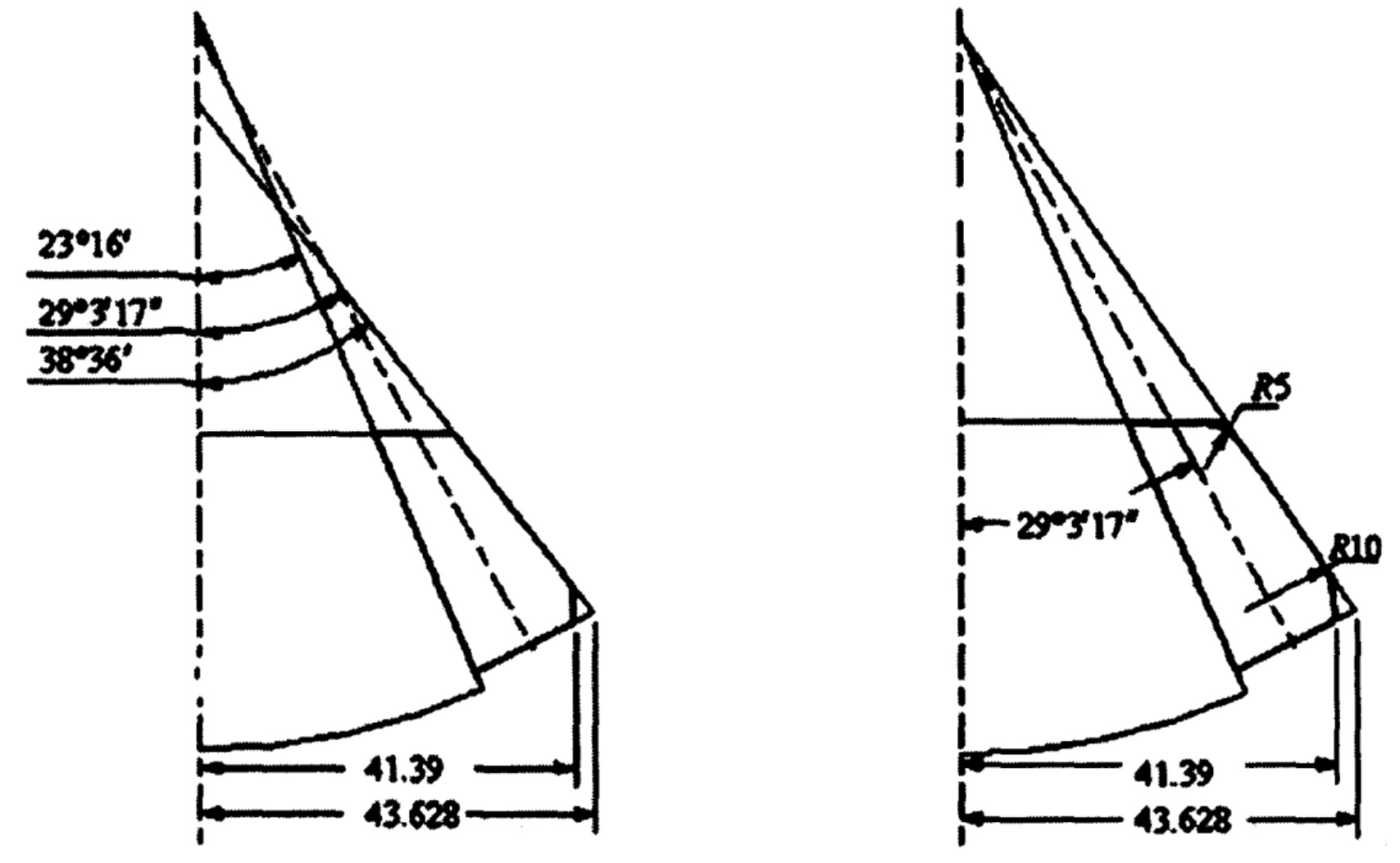

The improvement of the tooth shape of the bevel gear pre forging is mainly reflected in the tooth height. The bevel gear pre forging teeth are designed as contraction teeth with unequal top clearance. Compared with the double contraction teeth of the bevel gear forging, the tooth height becomes larger. When the final forging is realized, the teeth are mainly filled with rough piers. The transition arc connection is adopted at the junction of the end face and the tooth tip to make the tooth cavity filling more smoothly in the pre forging process. Fig. 4 and Fig. 5 respectively show the tooth comparison diagram of planetary gear and half shaft gear.