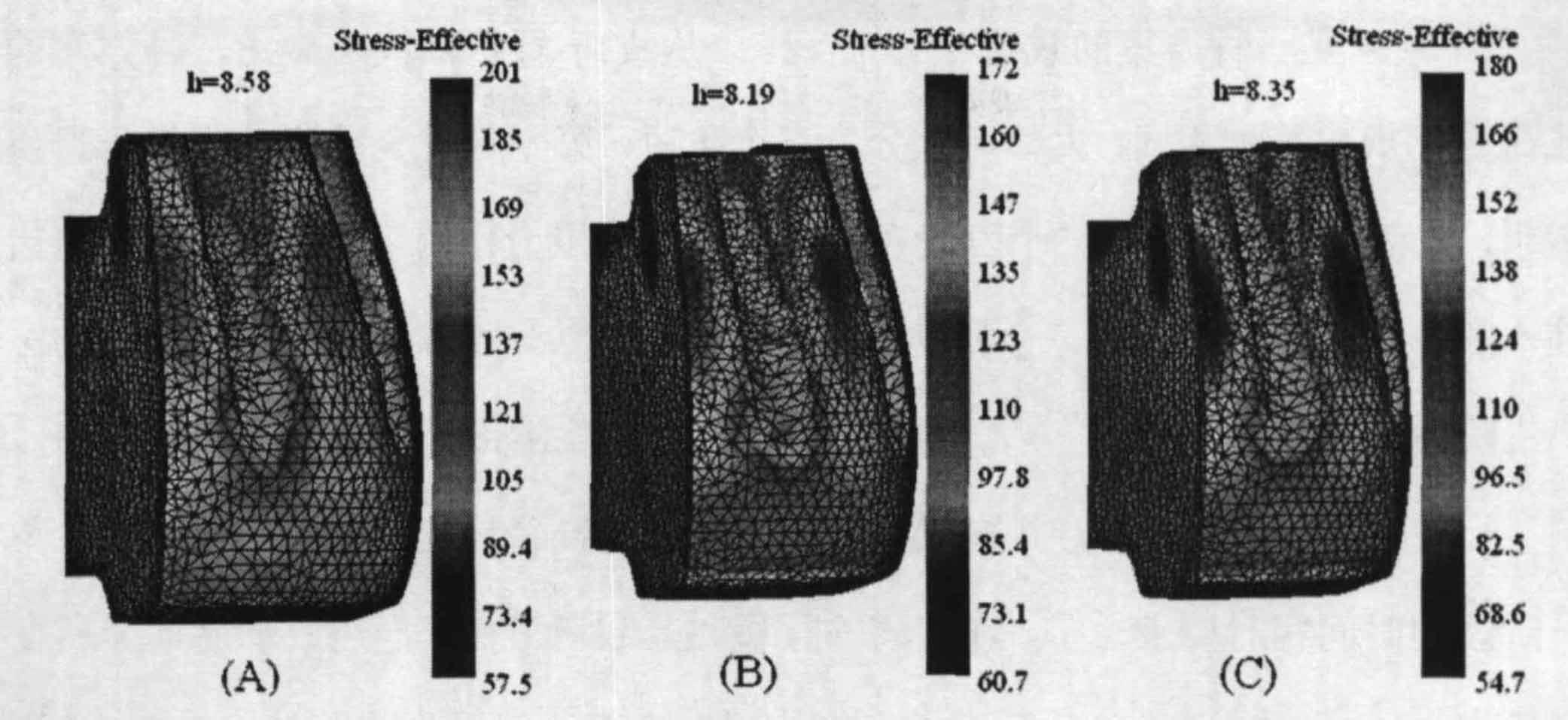

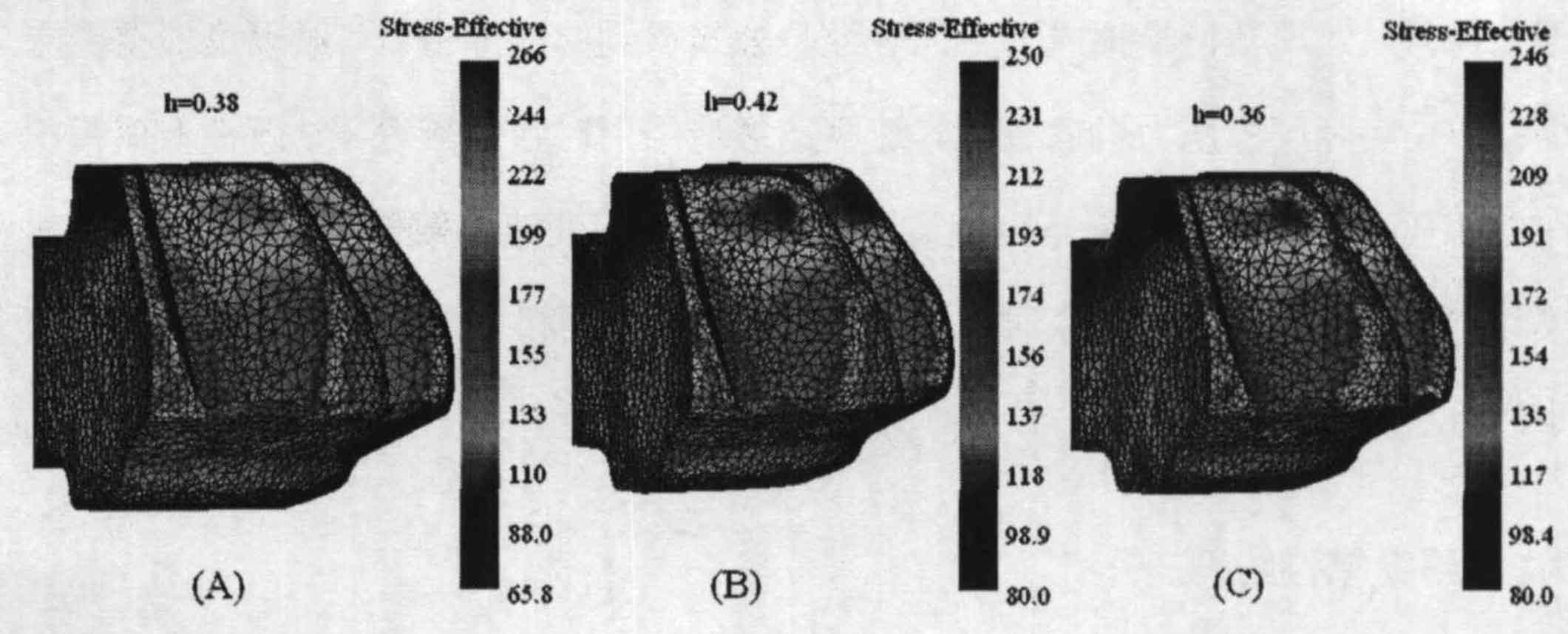

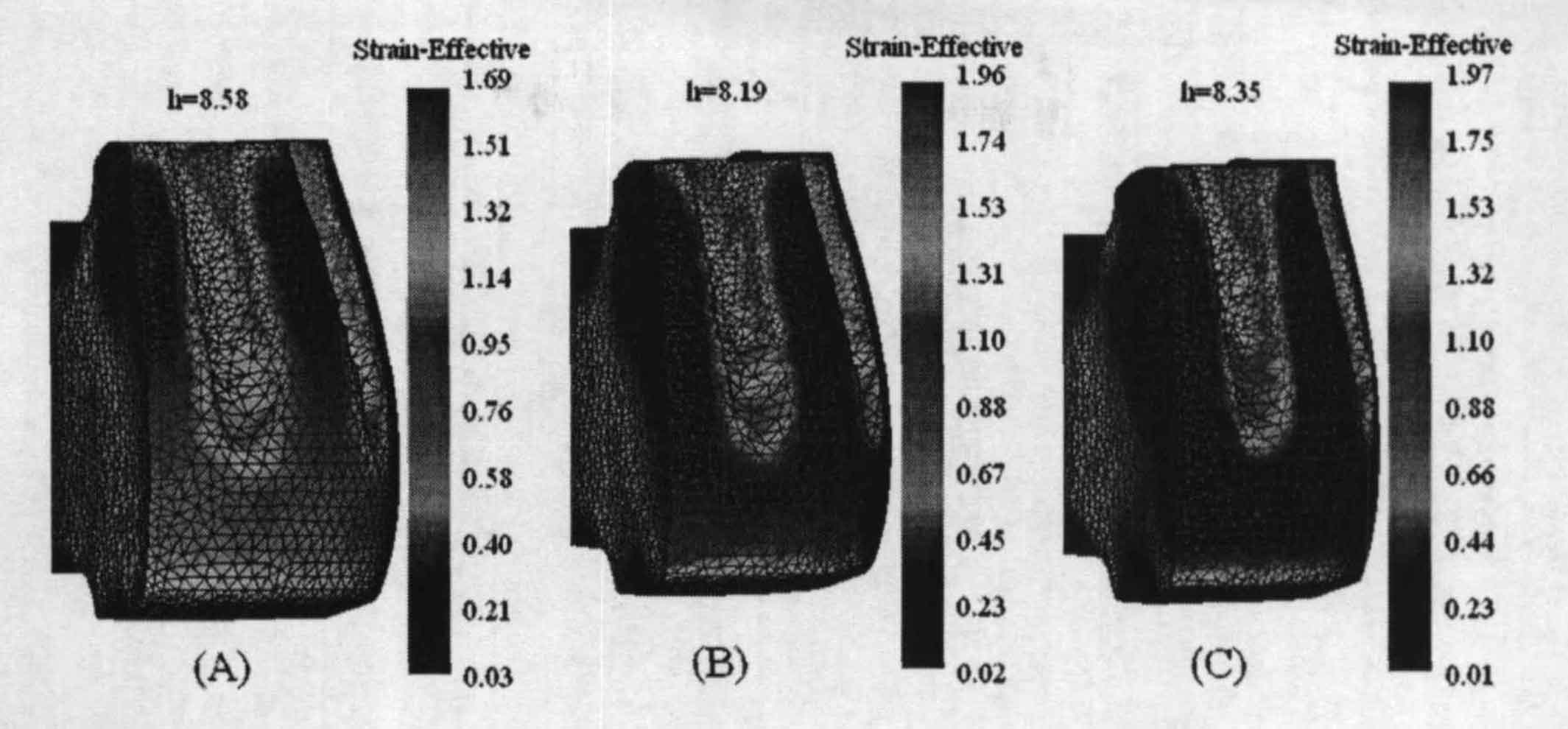

Strain is a physical quantity that represents the magnitude of deformation, the cumulative process of plastic deformation and the development process of plastic deformation. Fig. 1 and Fig. 2 respectively show the strain distribution of the three schemes at the end of the first stage and the second stage. At the initial stage of deformation, the outer surface of the upper end of the planetary gear in contact with the tooth top of the tooth mold first produces plastic deformation, and the strain decreases from the center of the tooth top outward. In the whole deformation process, the strain in the contact area between the planetary gear and the tooth top of the gear die is the largest, indicating that the deformation of this part is the largest. This is because one side of the metal at the tooth top of the tooth die is compressed and deformed along the radial direction to form the tooth root, and at the same time, the metal around it is forced to make a lateral movement to fill the tooth cavity. With the generation of the back cone flash, the maximum strain region begins to transfer from the tooth root at the upper end of the planetary gear to the back cone tooth root, indicating that after the back cone flash occurs, the metal deformation is mainly concentrated in the back cone tooth root, and the metal flows to the tooth cavity under the action of the resistance of the back cone flash. At the later stage of filling the tooth cavity, the planetary gear crown produces large strain. During the whole forming process, the cumulative deformation of the planetary gear crown is far less than that of the tooth root.

The distribution of strain field and the development process of strain in the three schemes are basically the same. In the figure, h is the closing modulus between the upper and lower dies when the back cone flash is generated. After the back cone flash is generated, the tooth top at the big end of the tooth die is completely wrapped by the high-temperature blank, and the temperature rises rapidly, which is easy to cause the tooth die to fail due to the high-temperature tempering and softening of the tooth top at the big end. After the back cone flash occurs, the longer the planetary gear forging time is, the more likely the tooth die will fail. Therefore, it is hoped that when the back cone flash occurs, the smaller the modulus is, the better. It can be seen from Figure 1 that when the back cone flash is generated in the scheme, the composite modulus is the smallest. It can be seen from Figure 2 that when the tooth cavity is basically filled, the composite modulus of the scheme is the largest, indicating that the tooth profile of the scheme is filled the earliest.

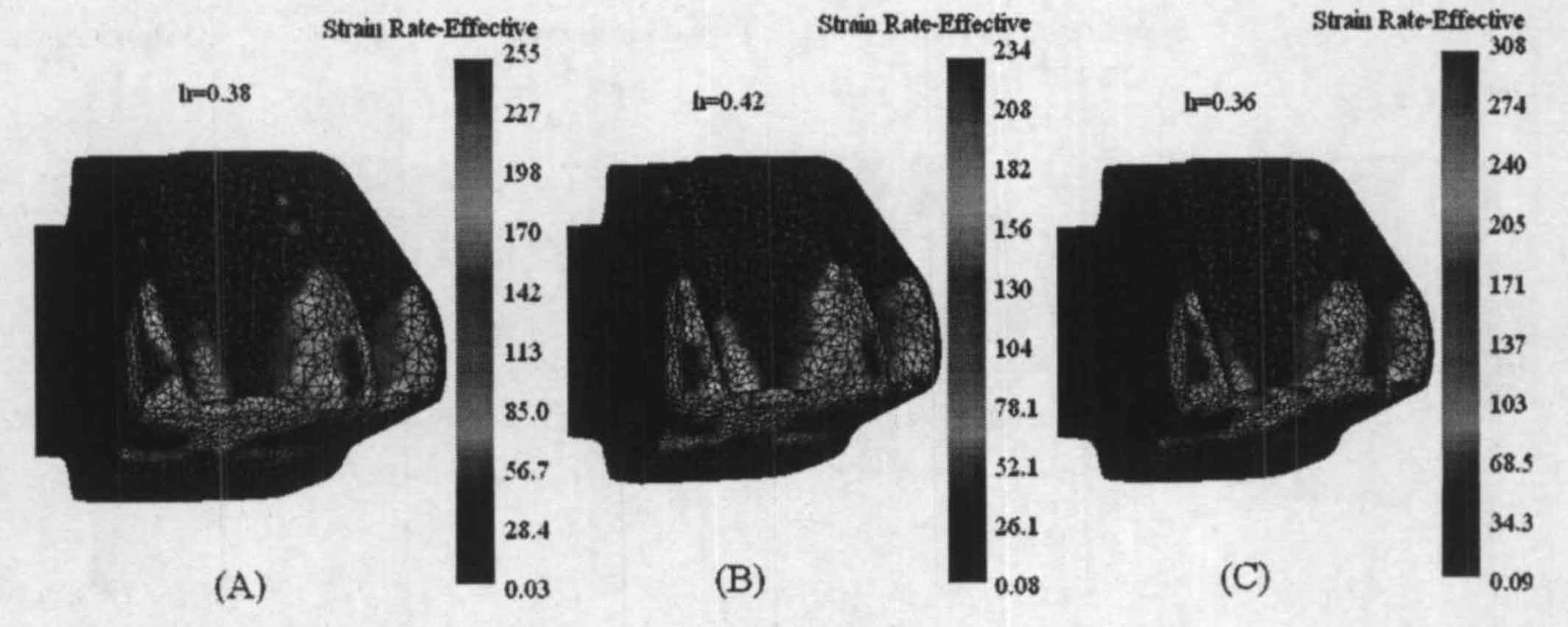

Strain rate is a physical quantity indicating the speed of deformation. Figure 3 and 4 show the strain rate distribution of the three schemes at the end of the first stage and the second stage. The distribution of strain rate in the deformation process shows that the larger strain rate is mainly distributed in the transition areas of the contact surface between the planetary gear and the die and the free surface of the planetary gear, especially in those transition areas that will contact the die in the next step. At the initial stage of deformation, the maximum strain rate is mainly pushed forward along the tooth top of the tooth die. After the formation of back cone flash, the maximum strain rate is mainly concentrated near the transition fillet of the big end tooth root, and expands from the tooth root to the tooth surface with the filling of the tooth cavity. In the whole deformation, the strain rate of the gear teeth is large, indicating that the metal deformation in these areas is the most severe. When the tooth cavity is basically full, the strain rate increases rapidly.