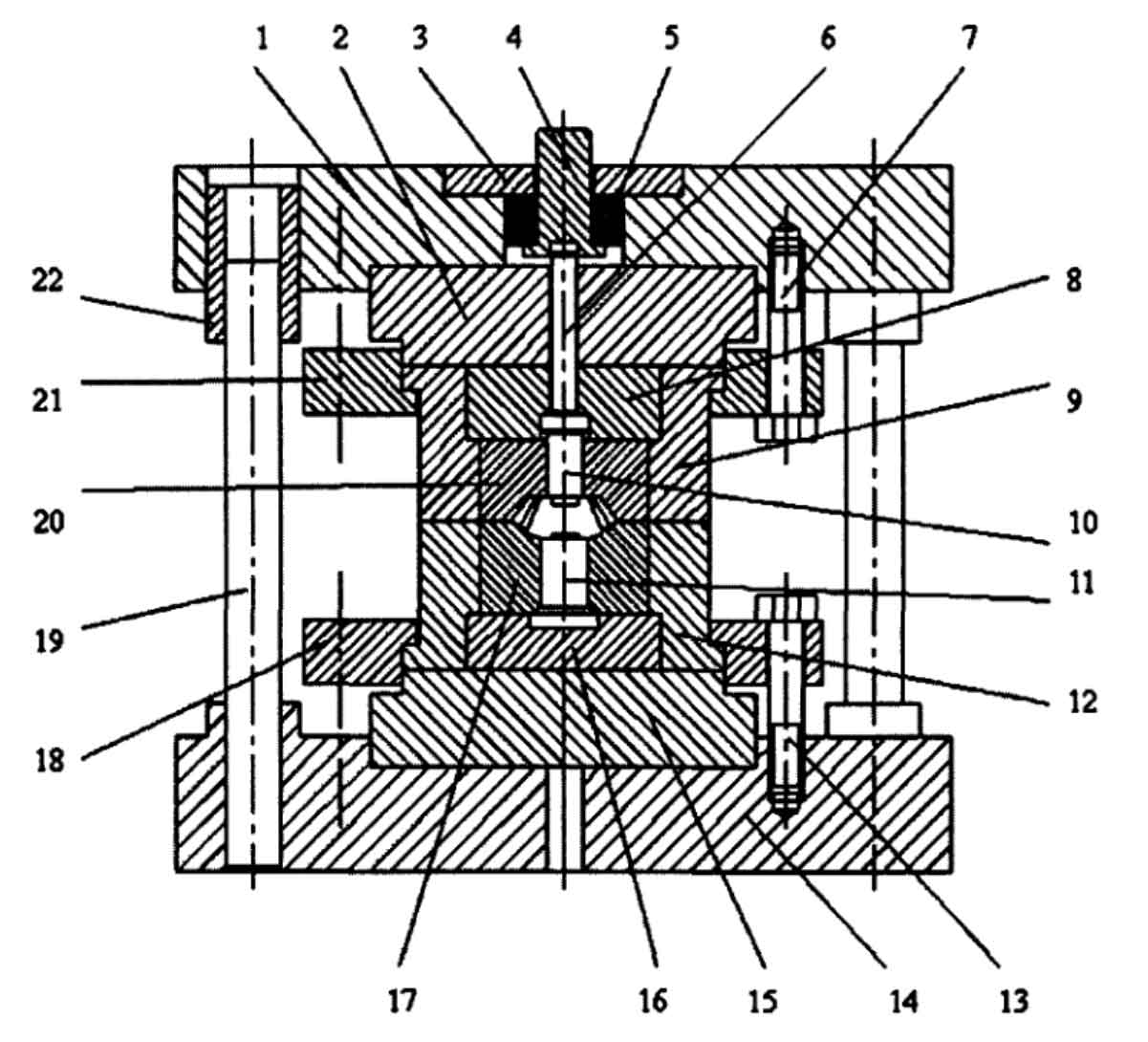

As shown in the figure, the structure diagram of the planetary gear pre forging die is given. The tooth die of the planetary gear pre forging die is on the upper die, the contact time between the tooth die and the high-temperature blank is short, and the temperature rise of the die is small, which is conducive to improving the service life of the tooth die. In addition, it can make it difficult for oxides to accumulate in the tooth die cavity. In order to ensure that the planetary gear forging is separated from the tooth die immediately after the forging is completed, the deformation of the planetary gear blank is large when the elastic ejector is installed on the upper die for pre forging, In order to ensure the accurate guidance of the upper and lower dies, the dies are guided by guide posts and guide sleeves.

The upper base plate 2 and the lower base plate 15 are respectively fixed on the upper template 1 and the lower template 14 with screws. In order to make the figure clear, the screws connecting the upper and lower base plates and the upper and lower templates are not drawn as shown in the figure. The planetary gear tooth mold 20 and the tooth mold sleeve 9 are prestressed, and the screw 7 uses the upper pressing ring 21 to fix the tooth mold sleeve on the upper template. The back cone formwork 17 and the back cone formwork sleeve 12 are prestressed, and the screw 13 uses the lower pressing ring 18 to fix the back cone formwork sleeve on the lower formwork.

The planetary gear forging starts, the upper punch 10 is at the lower limit position under the action of spring 5, the upper die goes down, the guide column is first introduced into the guide sleeve, and then the upper punch contacts with the blank, the spring is compressed, and the planetary gear blank begins to be forged. After the planetary gear forging is completed, the upper die goes up, the forging deformation force is eliminated, and the spring tension makes the forging separate from the gear die.