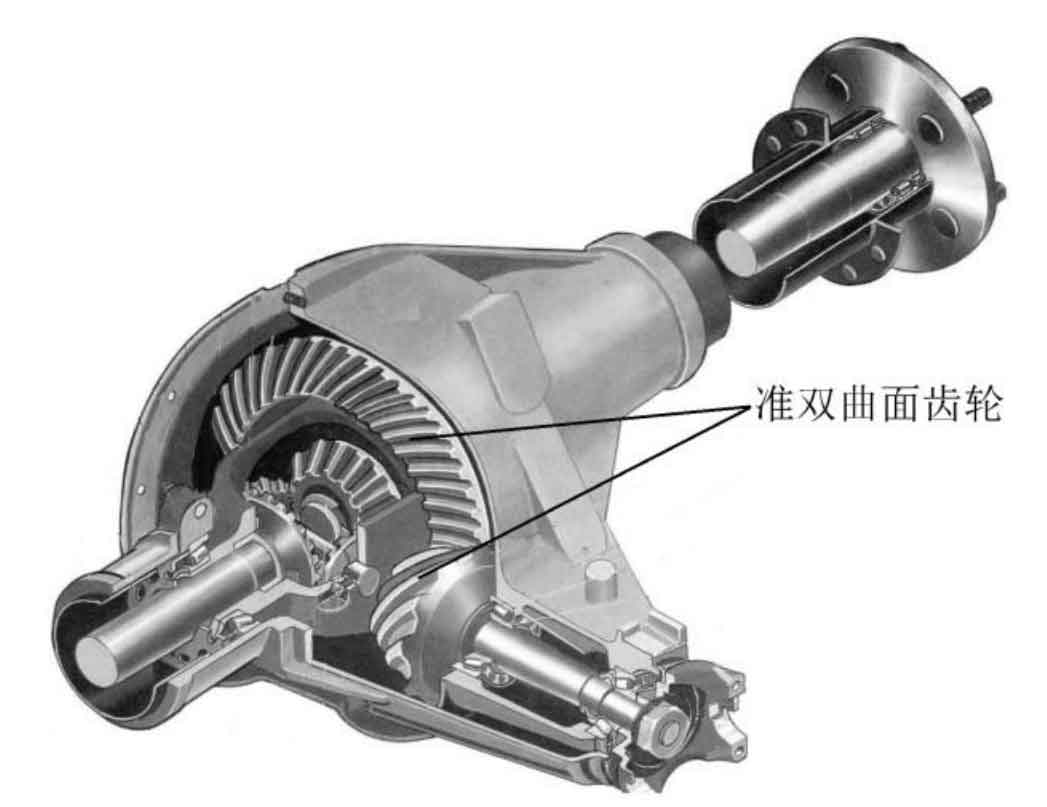

Hypoid gears (also known as hypoid gears) are used to transmit motion and power between staggered shafts, and are widely used in automobiles (Figure 1), shipbuilding industry, mining, metallurgy, electric power, hoisting machinery and industrial reducers.

In the 1940s, e.wildhaber of Gleason published a series of articles on the basic geometry of hypoid gears and the design of wheel blanks in the magazine American Machinist, and discussed its design and processing theory in detail from the aspects of geometry and kinematics, laying the foundation for subsequent research. Up to now, people still use his hypoid gear pitch model.

The existing hypoid gears mainly have two tooth systems: arc involute hypoid gears and cycloid hypoid gears with equal height teeth. The former is proposed by Gleason company of the United States, which uses the single division method to process the circular arc tooth line, and the tooth height shrinks along the direction of the tooth line, but the tooth groove and tooth crest width remain unchanged, so the teeth can be ground; The latter is divided into klinberg system (hereinafter referred to as “klinberg” system) and Oricon system (hereinafter referred to as “Austrian” system) according to the different gear milling manufacturers. It is processed by continuous indexing method. The tooth line is a part of the extended epicycloid, and the tooth height along the direction of the tooth line remains unchanged, but the width of the tooth groove and the tooth top shrinks, so it is impossible to grind the teeth. The “gram” system was proposed by Klingelnberg of Germany. It can be refined after heat treatment by scraping the hard tooth surface. The maximum machining diameter can reach 2000mm. It is mostly used in mining, metallurgy and hoisting machinery, and is suitable for single piece and small batch production; The “Austrian” system was proposed by the former oerlicon company of Switzerland (oerlicon was acquired by Klinger Berg in 1993 and established Klinger – oerlicon group). It cannot be ground or scraped. It is mainly used in various axle gears in the mass production automotive industry. For example, it has been used in Santana, Audi and other cars in China more than a decade ago. At present, it is used in light and heavy trucks SUVs and commercial vehicles are also more and more widely used, such as howo-t7h of China heavy duty truck, j6f of China FAW Jiefang high-end heavy truck, F330 speed leopard of light truck, Foton pickup truck and other models, which all use cycloid hypoid gears with equal high teeth (Fig. 2 to Fig. 5).