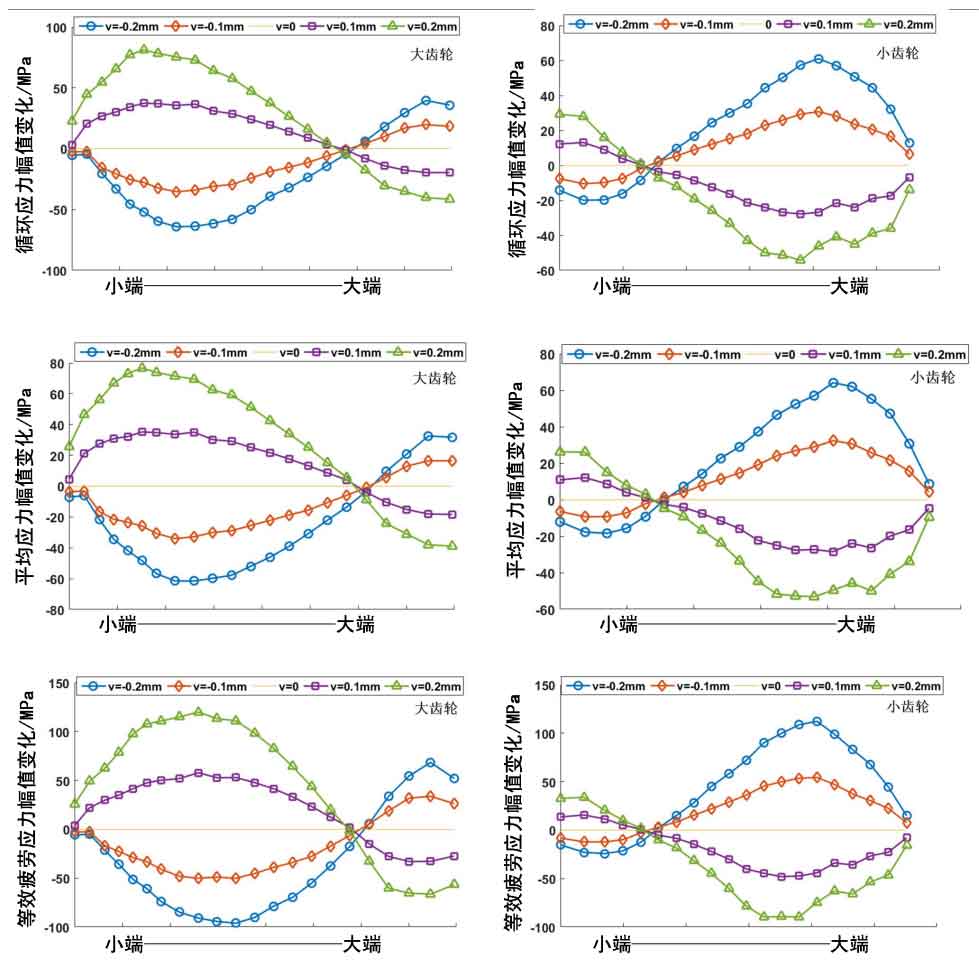

As shown in Fig. 1, the influence of the installation deviation V of the offset distance of the hypoid gear on the bending fatigue of the gear is shown. The abscissa in the figure represents the distance from the node at the small end of the tooth root to the node at the large end of the hypoid gear, and the ordinate is the stress amplitude of the corresponding parameter. From top to bottom, the changes of cyclic stress amplitude, average stress and equivalent fatigue stress relative to the ideal installation position with the influence of installation deviation are shown. In the figure, the left side is the large wheel of hypoid gear, and the right side is the three parameter changes of the small wheel pair of hypoid gear. It can be seen from the comparison of the stress amplitude of the three parameters that the change trend of the three parameters caused by the installation deviation is basically the same, but there are differences between the large and small wheels of the hypoid gear, and the influence of the installation deviation on the same meshing position is just the opposite. The main reason for the difference between the change trend of the large and small gears of the hypoid gear is that the change direction of the meshing imprint of the large and small gears of the hypoid gear and the direction of the meshing ellipse generated by the meshing force are different. The following is a detailed analysis of the causes of the changes in the fatigue parameters of the hypoid gears.

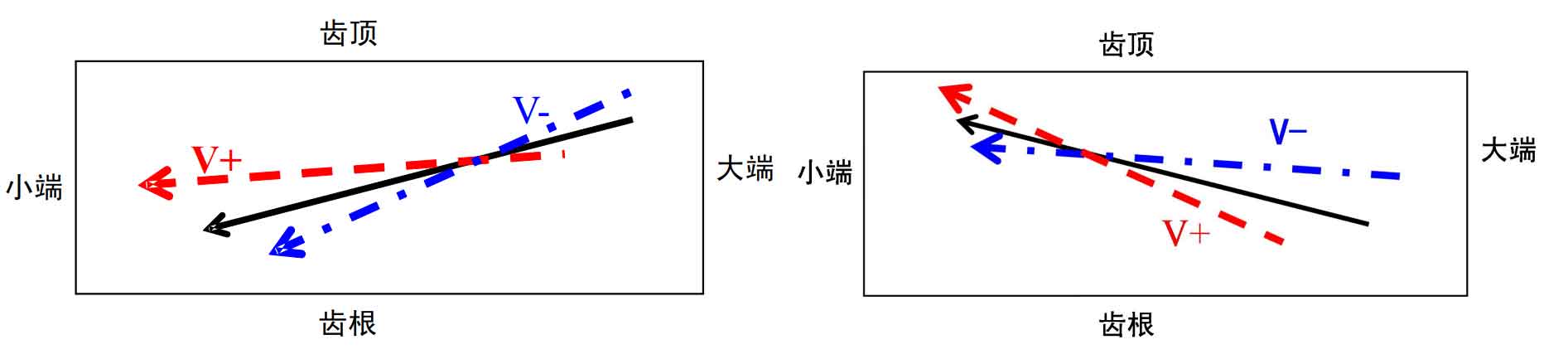

For the large hypoid gear, the direction of its meshing imprint is from the top of the big end to the root of the small end, while the long axis direction of the meshing ellipse is from the top of the small end to the root of the big end, as shown in Fig. 2 (a). When the value of V increases in a positive direction, the meshing point near the big end moves toward the tooth root direction, and the meshing point near the small end moves toward the tooth top direction, so that the tensile stress and the compressive stress near the big end tooth root decrease, but the tensile stress decreases more, and finally the three stresses decrease. The tensile stress and compressive stress near the tooth root of the small end increase, but the tensile stress increases more, so the three stresses increase. For the small end position, the meshing force itself is very small when the meshing force is withdrawn, so the tensile stress and compressive stress do not change much. When the V value increases in the negative direction, the meshing point near the big end moves toward the tooth top direction, and the meshing point near the small end moves toward the tooth root direction. The tensile and compressive stresses at the tooth root of the big end increase, so the three stress values increase, and the tensile and compressive stresses near the small end also decrease, and the three stress values decrease. It can be seen from Fig. 1 that there is a point where the stress at the root point does not change near the big end.

For the hypoid gear pinion, the direction of its meshing line is from the root of the big end to the tip of the small end, as shown in Fig. 2 (b). When the V value increases in a positive direction, the meshing point near the big end moves toward the root of the tooth, and the meshing point near the small end moves toward the tip of the tooth, so that the tensile stress and the compressive stress generated by the meshing point near the big end are reduced. However, the tensile stress decreases significantly, so the three stress values are reduced. The tensile stress and compressive stress of the corresponding engagement point near the small end increase, but the tensile stress increases significantly, so the three stress values increase. However, since the force at the meshing point is very small when entering and exiting the meshing, the change of the meshing point at both ends of the hypoid gear has little influence on the stress change at the tooth root. When the value of V increases in the negative direction, the meshing point near the big end moves toward the tooth crest direction, and the meshing point near the small end moves toward the tooth root direction, so that the tensile stress and the compressive stress at the tooth root near the small end of the hypoid gear pinion increase, but the tensile stress increases significantly, so the three stresses increase. The tensile stress and compressive stress of the tooth root near the big end of the hypoid gear pinion are reduced, but the tensile stress is significantly reduced, so the three stresses are reduced. It can be seen from the figure that there is a point where the stress at the root point does not change near the small end.

To sum up, when the V value increases in a positive direction, the fatigue stress of the tooth root near the small end at the middle position of the large wheel of the hypoid gear increases, and the fatigue stress of the tooth root near the small end of the small wheel of the hypoid gear increases due to the edge contact. When the V value increases in the negative direction, the fatigue stress of the big end tooth root of the hypoid gear increases due to the contact of the big end edge, and the fatigue stress near the big end in the middle of the hypoid gear wheel increases.

From the above analysis, it can be seen that the change of V value will cause a strong change in the fatigue stress parameters of the tooth root. The negative increase of V value will easily lead to the large end contact of the large wheel of the hypoid gear and increase the root stress of the large end of the small wheel of the hypoid gear. The positive increase of V value will cause the small end contact of the small wheel of the hypoid gear and increase the fatigue stress of the root of the small end of the large wheel of the hypoid gear. The maximum increase of fatigue stress of large wheel of hypoid gear is 110MPa at the middle part and 70MPa at the big end; The fatigue stress of hypoid gear pinion increases by 120MPa at the middle part and 38Mpa at the small end; The point where the stress of the big wheel of the hypoid gear does not change is close to the big end, and the point where the stress of the small wheel of the hypoid gear does not change is close to the small end.