In the development of NVH for pure electric vehicles, the noise problem of the reducer is often found. The howling of the reducer does not account for a high proportion of the overall noise component. However, since the new energy vehicles do not have the masking effect of the engine, and the speed of the reducer is higher than that of the traditional fuel vehicles, and the howling noise of the general reducer is at the sensitive position of the human ear, it needs to be focused and rectified.

The reducer noise mainly includes two types: gear whine and gear rattle. The knocking of the reducer is mainly caused by the meshing impact of the non bearing reducer gear caused by the torque fluctuation at the input end of the reducer; The howling of the reducer is caused by the transmission error in the meshing process of the reducer gear system.

Reducer howling is a serious quality problem of automobiles, especially for pure electric vehicles. Therefore, reducer howling must be reduced or eliminated. There are several methods to solve the problem of vibration and noise:

① Moving the natural mode of the system out of the excitation frequency range;

② Reduce or eliminate excitation;

③ Increase the structural damping to reduce the response value;

④ Change or eliminate the vibration transmission channel.

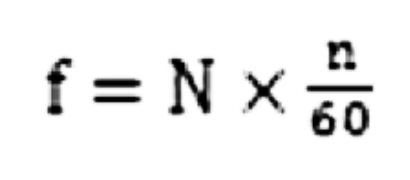

Taking the reducer of a pure electric vehicle as an example, the number of driving gear teeth of the first stage reduction gear pair of the reducer is 14, and the reducer gear generates an impact when it rotates one tooth, that is, the number of impact per revolution is equal to the number of teeth of the reducer gear, so the meshing frequency formula of the reducer gear is:

Where, f is the engagement frequency (Hz); N is the number of teeth of the reducer gear; N is the speed of the reducer gear (Rmin).

The speed range of the motor equipped with the pure electric vehicle is 0-15000 rpm, and the minimum modal frequency of the reducer housing is 450 Hz. The speed of the input shaft of the reducer is the same as the output speed of the motor. Thus, the range of the meshing frequency can be obtained according to the formula: 0-3500 Hz, while the minimum modal frequency of the reducer housing is 450 Hz, and there are about 20 modal frequencies within 3500 Hz. Therefore, the modal frequency of the reducer system cannot avoid the excitation frequency. Another way to reduce the noise of the reducer is to reduce the excitation.