Compared with the traditional cylindrical gear, the tooth line of vh-catt is special. It is arc-shaped on the plane that extends along a cylindrical surface coaxial with the gear, while the tooth lines of other gears, such as spur gears and helical gears, are straight lines and oblique lines. Vh-catt transmission is a better new transmission mode.

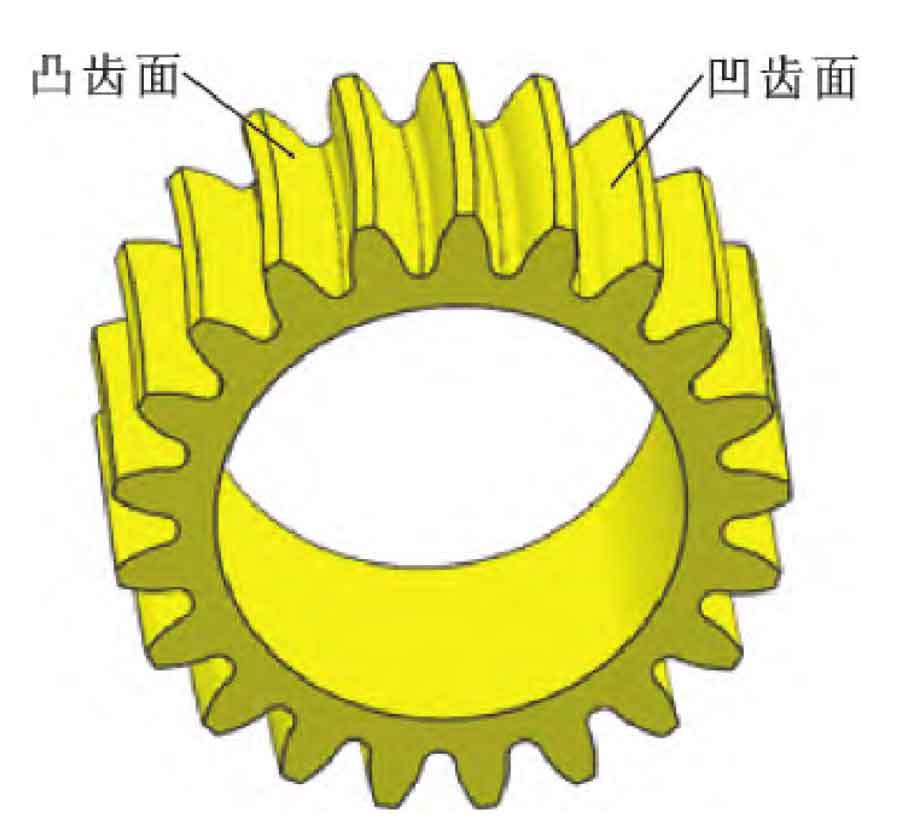

As shown in Fig. 1, the meshing tooth line of vh-catt is a spatial curve. From the end face of the gear, the gear teeth on the middle section are involute profiles, and the other sections are variable hyperbolic profiles. The meshing contact line of vh-catt is longer than that of spur gear of the same size; The tooth surface is arched and consists of concave and convex surfaces. Therefore, theoretically speaking, vh-catt has better bearing capacity, transmission stability and fatigue strength.

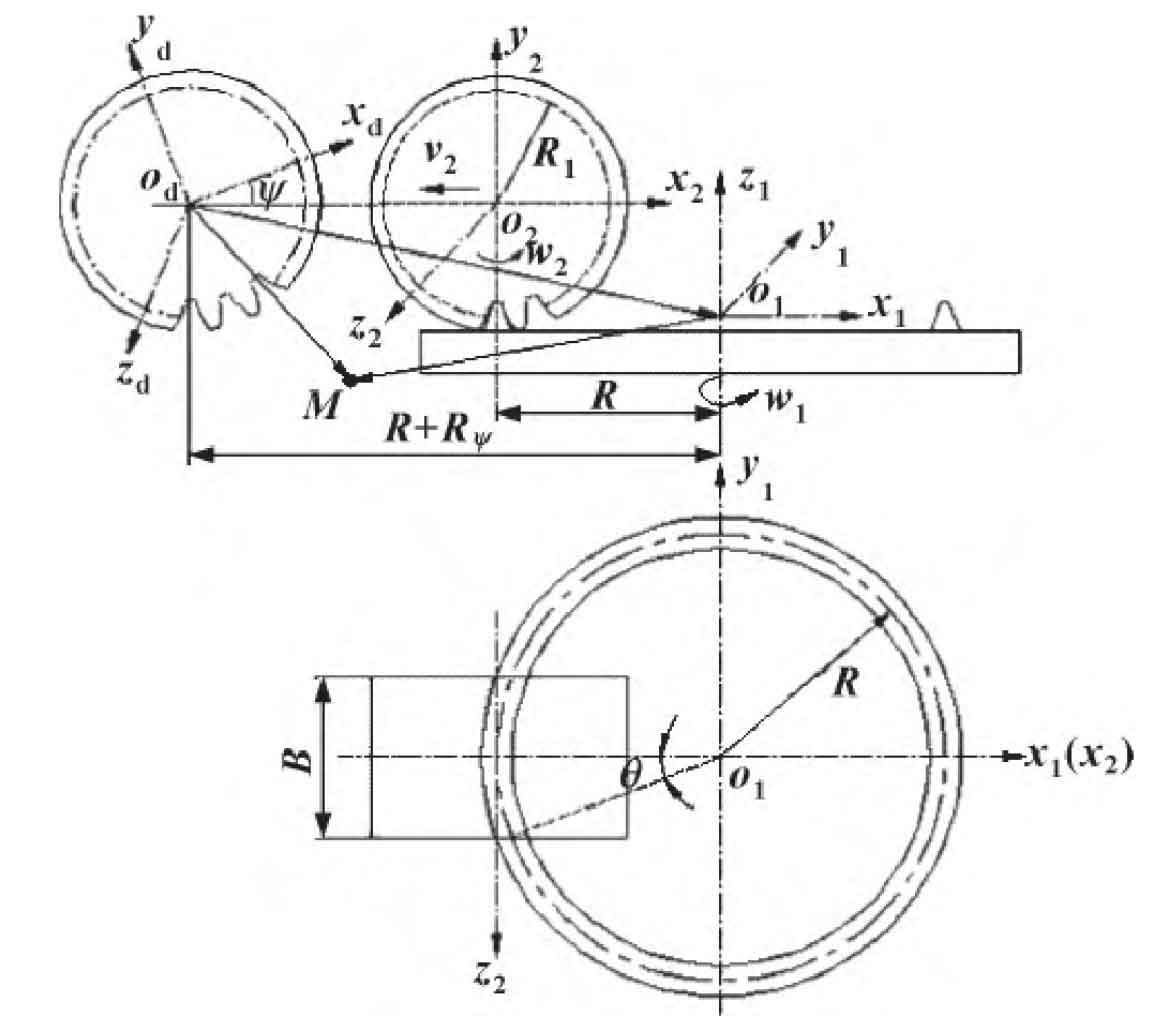

As shown in Fig. 2, in the process of machining the gear with vh-catt rotary machining cutter head, the high-speed rotary machining of the cutter head along Z1 axis is the main motion in the gear milling process. While the cutter head rotates, the gear blank makes a normal motion in x1 OZ1 plane. This motion is the feed motion in the gear milling process, that is, the horizontal motion of the gear blank along the X1 axis and the rotational motion of the gear blank around the Z2 axis. After one tooth slot is processed, the tooth blank moves back to the initial position along the X1 axis, the tooth blank rotates around Z2 for indexing, and then the next tooth slot of the gear is processed until the entire vh-catt tooth surface is processed.