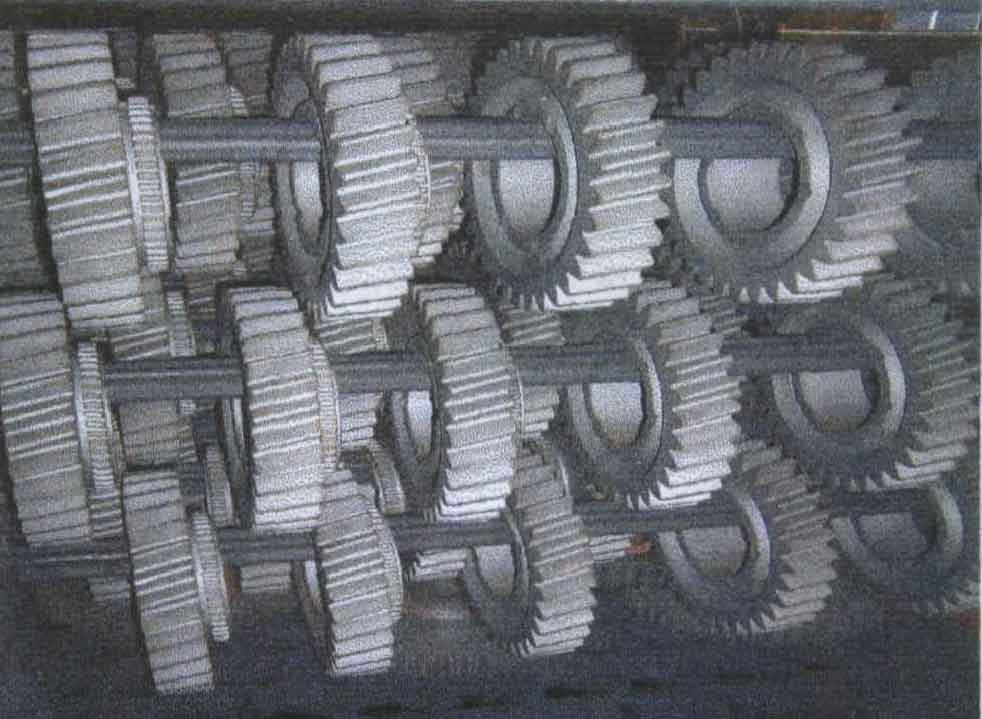

Cylindrical helical gear is a common transmission component in industrial machinery, which is widely used in transportation, aviation, shipbuilding and other industries. In the process of industrialization and informatization, the parameter design and related detection technology in the process of cylindrical helical gear processing are still hot research directions.

Compared with the general cylindrical spur gear, the tooth surface structure of the cylindrical helical gear is relatively complex. In the process of machining, the tooth line will generate non axial force, resulting in a certain manufacturing error of the processed gear. Because the accuracy of the machining parameters of the cylindrical helical gear directly determines the performance and life of the whole mechanical equipment in the working process, the gear machining parameter detection system is very important in the machining process of the cylindrical helical gear.

The traditional numerical control gear measuring system can accurately measure the processing parameters of the cylindrical helical gear in the actual work process, but it does not consider the small errors in the gear processing and manufacturing process. Compared with the real parameter results, the measurement results will inevitably have a large deviation. In view of this, a measuring system of cylindrical helical gear machining parameters is designed, which takes manufacturing error into account.