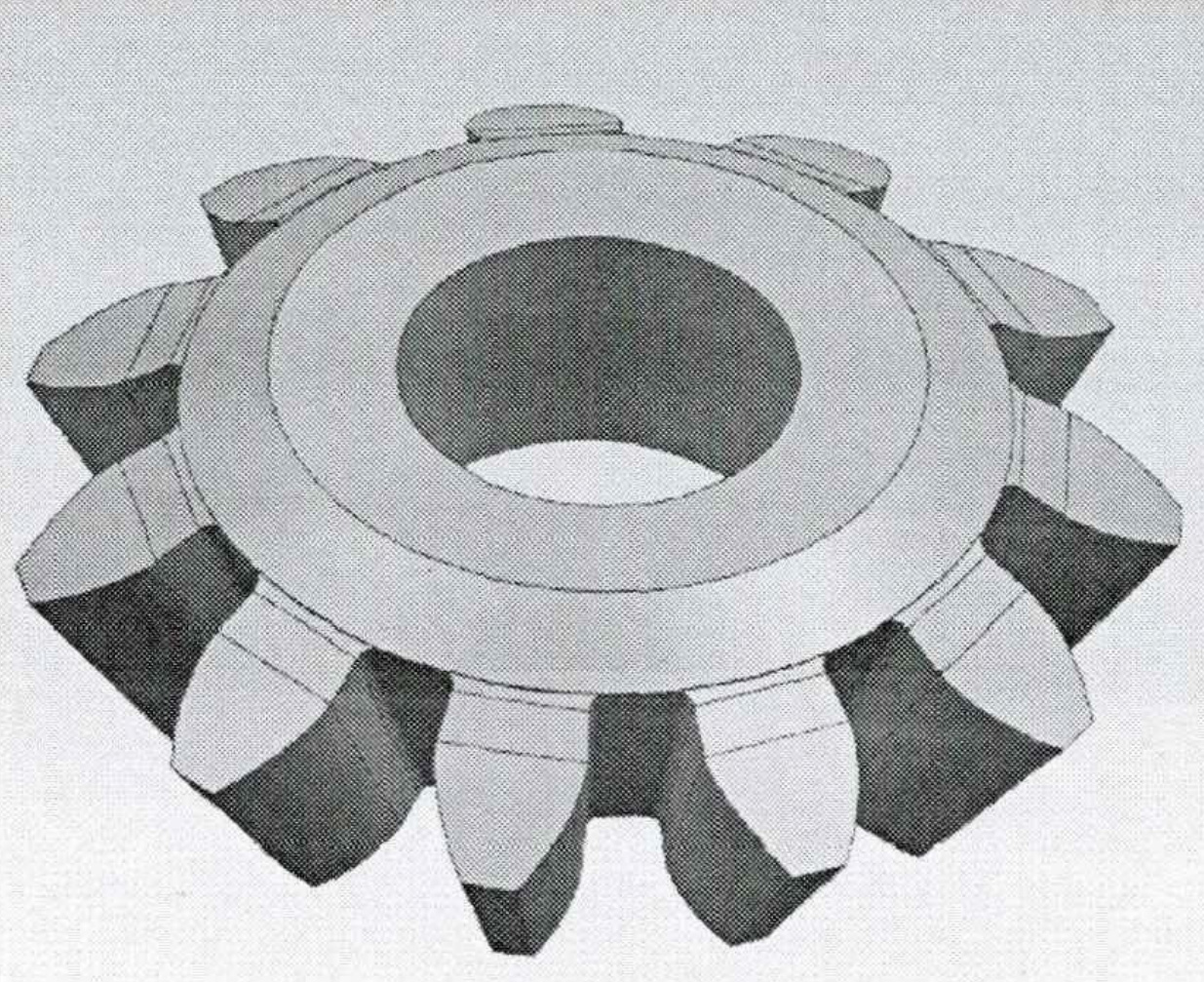

Involute spur gear pair is widely used in modern mechanical system because of its excellent performance. The working performance of spur gear pair is deeply affected by the meshing stiffness, so that the meshing stiffness becomes the main excitation source of the vibration of spur gear pair. Under the influence of severe service conditions, the spur gear pair is prone to spalling failure, which will have a great impact on the vibration characteristics of the spur gear pair, and even cause the transmission failure of the spur gear pair.

A large number of scholars at home and abroad have conducted in-depth research on the meshing stiffness and vibration characteristics of spalling fault spur gear pairs. Chaari et al. Derived the analytical formula for calculating the time-varying meshing stiffness of spalling fault spur gear pair through the tooth surface rectangle. Saxena et al. [5] discussed the change law of meshing stiffness of spur gear pair under different spalling shapes. Wang Xinlong studied the influence of tooth surface spalling and edge contact on the meshing stiffness of spur gear pairs. Endo analyzed the influence of spalling size on the meshing stiffness of spur gear pair by means of finite element model. Parey et al. Established a 6-DOF spur gear transmission dynamics model with root crack, and studied the fault detection method of spur gear pair based on empirical mode decomposition. Wu et al. Analyzed the change law of meshing stiffness of spur gear pair with crack propagation, and obtained the evolution process of 6-DOF spur gear system by means of statistical method. Cheng et al. Analyzed the influence mechanism of crack fault on the dynamic influence of spur gear pair. Ma et al. Established the dynamic model of spur gear pair with spalling fault and analyzed its dynamic response characteristics. Saxena et al. Established the dynamic model of spur gear pair considering the tooth surface friction and spalling failure.

In the meshing process of spur gear pair, sliding friction occurs on the tooth surface, flash temperature occurs on the tooth surface, and slight deformation occurs on the tooth profile, resulting in flash temperature stiffness. The influence of flash temperature has not been taken into account in the above-mentioned research on spalling fault spur gear pair. Therefore, by establishing a comprehensive model of tooth surface flash temperature factor and spalling fault, the stiffness change in the transmission process of spur gear pair is deduced, and the influence of vibration characteristics of spur gear pair is studied to provide reference for actual engineering fault detection.

Based on block flash temperature theory, the dynamic equation of spur gear pair system considering flash temperature is established, and the following conclusions are obtained: 1) during the meshing transmission of spur gear pair, the sliding friction between two wheels generates heat, and the spur gear profile is thermally deformed, resulting in flash temperature stiffness; 2) The two spur gears at the meshing node make pure rolling, the heat generated by friction is small, and the deformation of the corresponding gear profile is small, which makes the flash temperature stiffness of the two gears at the meshing node larger, while the comprehensive meshing stiffness of the spur gear pair decreases as a whole, and as the actual meshing point is far away from the meshing node, the meshing stiffness of the spur gear pair decreases and the amplitude increases; 3) When the tooth surface flash temperature is considered, the spalling fault spur gear pair is affected by the meshing stiffness. There is obvious periodic pulse vibration in the time domain of the vibration of the spur gear pair, and the frequency in the frequency domain is consistent with the rotating shaft frequency fr. the repetition frequency of the adjacent impact peak is the meshing frequency FM of the spur gear pair, accompanied by the high multiple frequency NFM (n = 1, 2, 3…) and the sideband, and the interval of the sideband is the rotating shaft frequency.