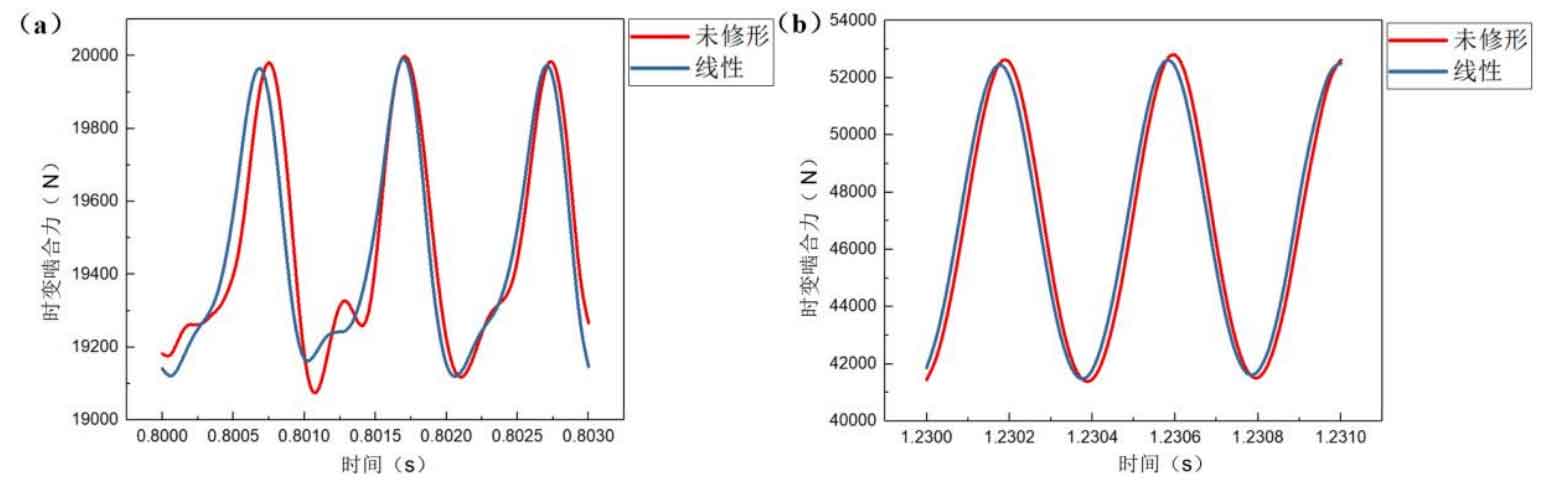

The linear optimization modification scheme of long tooth profile addendum is the modification amount of driving gear 3 μ m. Modification amount of driven wheel 3 μ m。 Figure 1 shows the time varying meshing force curves of the helical gear pair before and after the linear optimization modification of the long tooth profile addendum at different speeds. It can be seen that the time varying meshing force of the helical gear pair of the reducer of an electric vehicle after the optimization modification decreases at low, medium and high speeds. Although the reduction amplitude is small and only a few newtons, it can be seen from Figure 1 (a) that this scheme effectively alleviates the meshing impact of the helical gear pair at low speeds.

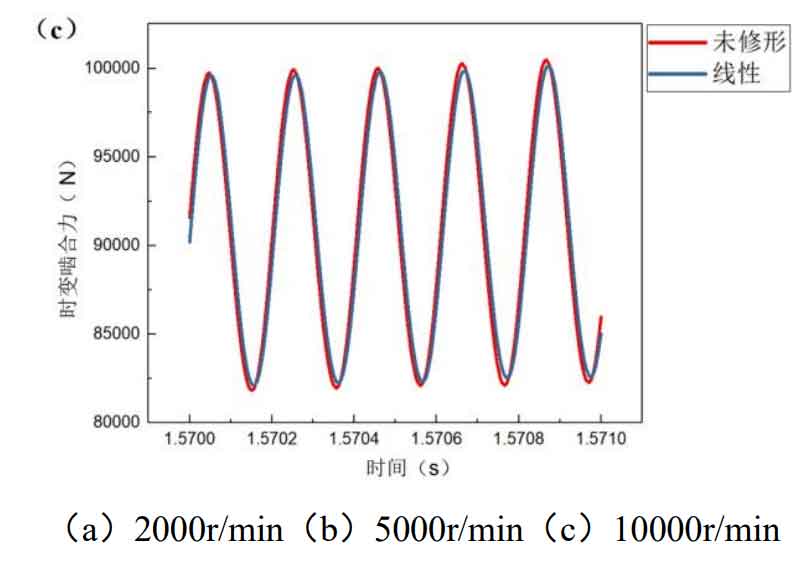

Figure 2 shows the time-varying meshing stiffness curves before and after the linear optimization modification of the helical gear pair through the long tooth profile addendum. Obviously, the time-varying meshing stiffness of the helical gear pair of the reducer of an electric vehicle after optimization and modification decreases significantly, with the peak value from 5.1 × 108N/m becomes 4.89 × 108N/m, decreased by 4.1%.

Therefore, it can be considered that the linear optimization modification scheme of the addendum of long tooth profile can reduce the dynamic excitation of the helical gear pair of an electric vehicle gearbox to a certain extent, so as to alleviate the meshing impact between the teeth of the helical gear pair and reduce the vibration of the helical gear transmission.