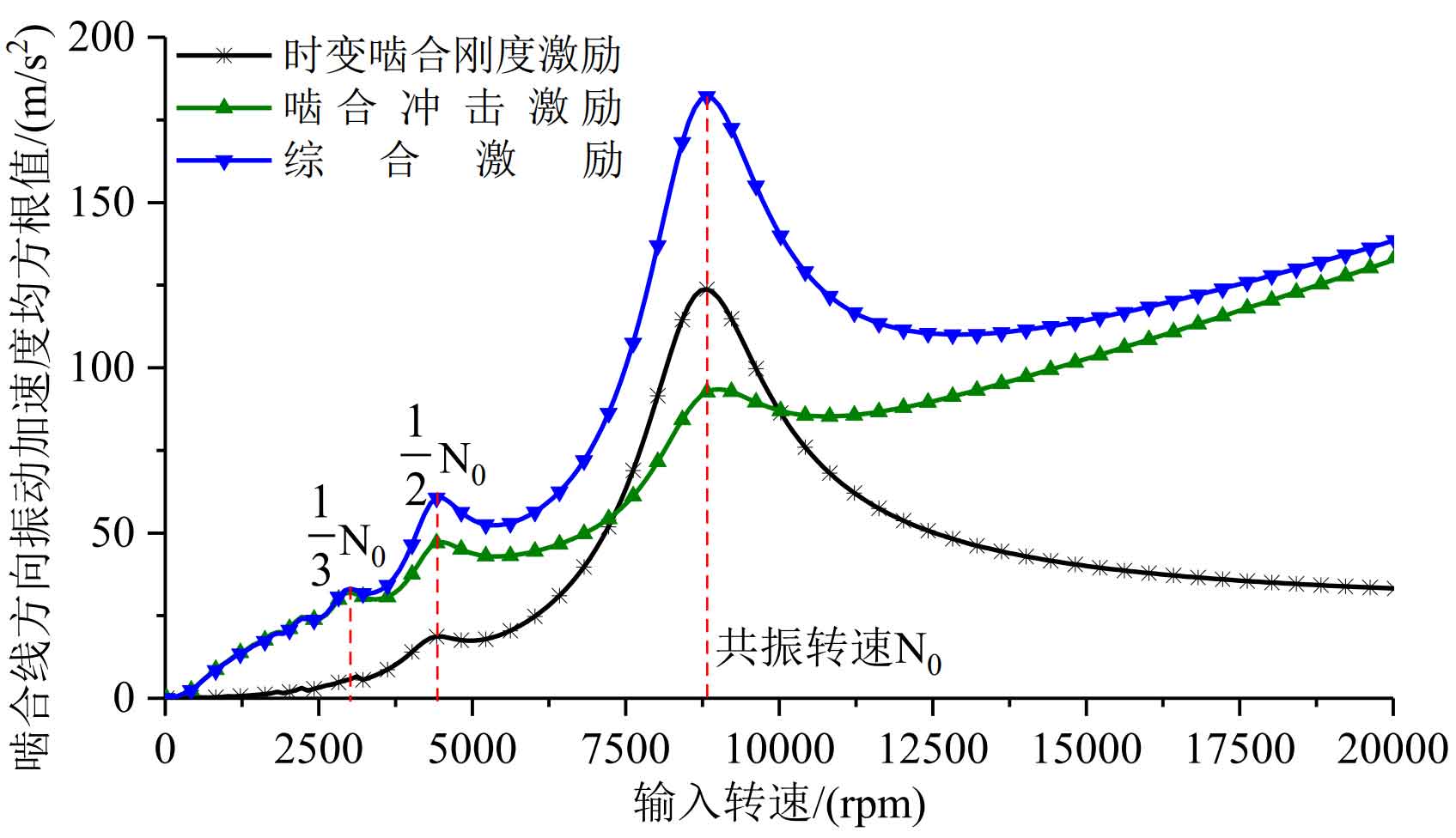

In order to study the influence of the above two excitation factors on the system vibration, the vibration speed diagram of single-stage helical gear transmission gear end face meshing line direction under three excitation forms when the input torque is 100N · m is compared, as shown in Figure 1.

Figure 1 shows that the vibration response of the system under meshing impact excitation is greater than that under time-varying meshing stiffness excitation; This is because the mean value of the time-varying meshing stiffness of the helical gear pair is large, and the vibration response of the system under the excitation of the time-varying meshing stiffness is small. When the speed and torque are unchanged, the meshing impact force is large when the meshing stiffness is large. Therefore, the system vibration generated by the meshing impact excitation under the low speed is significantly greater than the time-varying meshing stiffness excitation; In the over resonance area, with the increase of the rotational speed, the system vibration under meshing impact excitation tends to be consistent with the system vibration under comprehensive excitation, which indicates that the time-varying meshing stiffness has less and less influence on the system vibration under high rotational speed, and meshing impact is the main excitation component of the system.

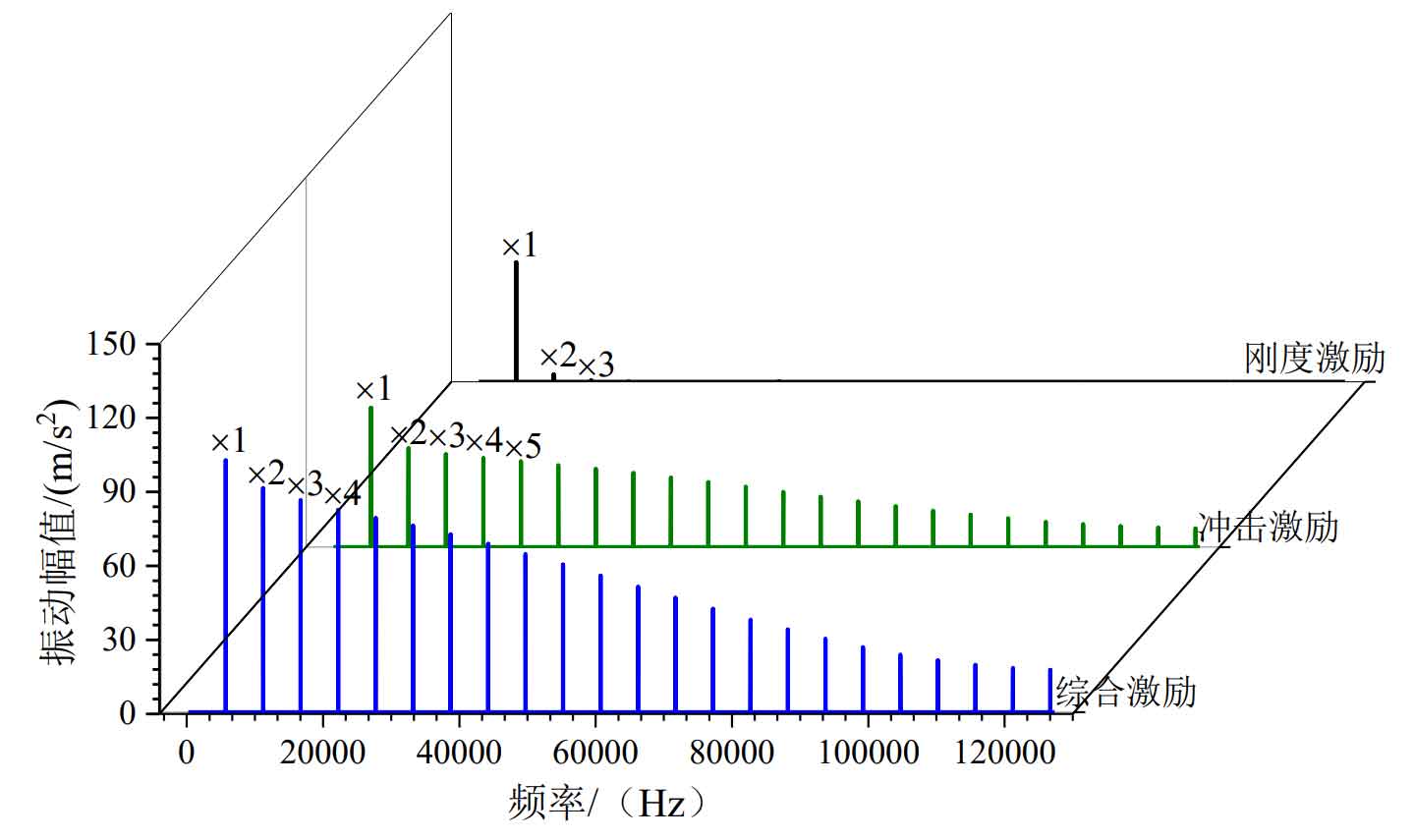

In order to compare the system vibration response under three excitation forms, the frequency domain diagram of single-stage helical gear transmission under three excitation forms at 15000 rpm is made, as shown in Figure 2.

Figure 2 shows the frequency domain response of single-stage helical gear drive under three different excitation conditions at 15000rpm. It can be clearly seen from the figure that the amplitude at the frequency multiplication 1 is the largest, because the amplitude of the frequency multiplication 1 is the highest, and the frequency multiplication 1 is the closest to the resonant frequency at this speed; Under the excitation of time-varying meshing stiffness, the third harmonic generation basically attenuates to zero, while in the presence of the impact excitation component, the 20th harmonic generation still has a certain amplitude, which attenuates slowly. This is because the meshing impact excitation frequency is complex, and the system forms many higher harmonics, that is, the existence of impact excitation makes the system vibration more complex. This situation is more prominent when the helical gear system is at high speed. Therefore, the impact component should be considered more when the high-speed helical gear transmission is optimized for vibration reduction.