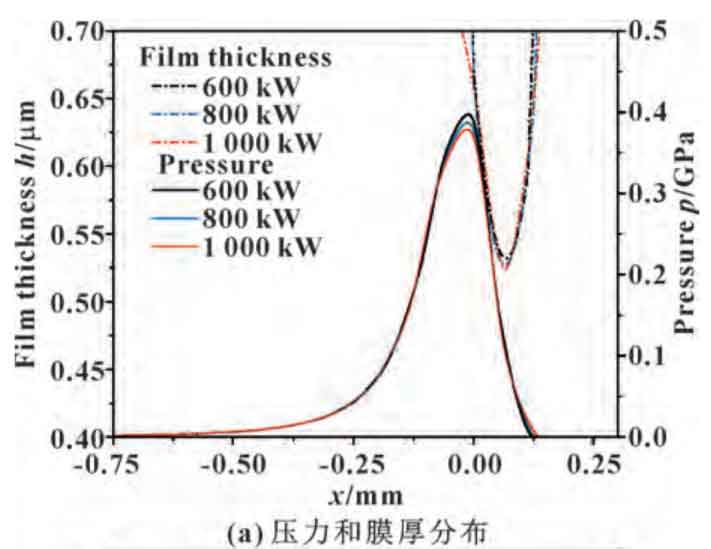

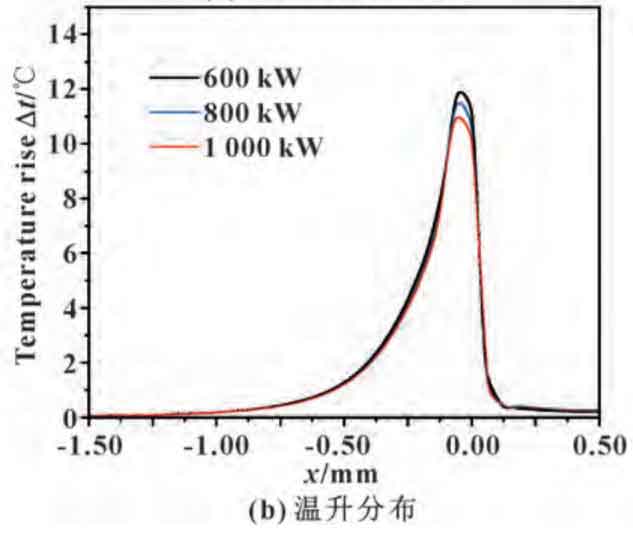

Taking the driven cone as the research object, when the rotating speed of the fixed spiral bevel gear is 20 132 r/min, the oil supply temperature is 140 ℃, and the lubrication characteristics of the meshing area are studied at 60%, 70%, 80%, 90%, and 100% of the design point power (expressed in Po). The two-dimensional contour curves of oil film pressure, oil film thickness and oil film temperature rise are shown in the figure when the power is 60%, 80% and 100% of the design point speed. The changes of maximum oil film pressure, minimum oil film thickness and maximum oil film temperature rise under various working conditions are shown in Table 1. As shown in the figure, when the rotating speed is fixed, the oil film pressure, oil film thickness and oil film temperature rise of spiral bevel gear will decrease with the increase of power.

| N/( r·min-1) | hmin / μm | pmax /GPa | Δtmax /℃ |

| 600 | 0.536 | 0.389 | 11.892 |

| 700 | 0.531 | 0.384 | 11.614 |

| 800 | 0.528 | 0.378 | 11.340 |

| 900 | 0.526 | 0.374 | 11.077 |

| 1000 | 0.524 | 0.369 | 10.823 |

The decrease of oil film pressure is due to the increase of contact load which will inhibit the phenomenon of oil film necking. The maximum temperature rise is also reduced by the influence of the maximum pressure drop, while the minimum oil film thickness does not increase with the decrease of the maximum pressure. It is because the decrease of the maximum pressure leads to the decrease of the lubricating oil viscosity and the decrease of the bearing capacity of the lubricating oil, At the same time, the increase of contact load leads to the increase of elastic deformation and other factors.

| Mk | 60%No | 70%No | 80%No | 90%No | 100%No |

| hmin | 0.053 | 0.043 | 0.031 | 0.023 | — |

| pmax | 0.093 | -0.090 | 0.085 | 0.082 | — |

| Δtmax | 0.247 | 0.244 | 0.239 | 0.235 | — |

According to Table 1 and the formula, the corresponding sensitivity coefficient of each oil film characteristic parameter when the power changes is shown in Table 2. It can be seen that the sensitivity coefficients of minimum thickness, maximum pressure and maximum temperature rise at the design point are small, so the oil film characteristic parameters can be adjusted slightly by power.