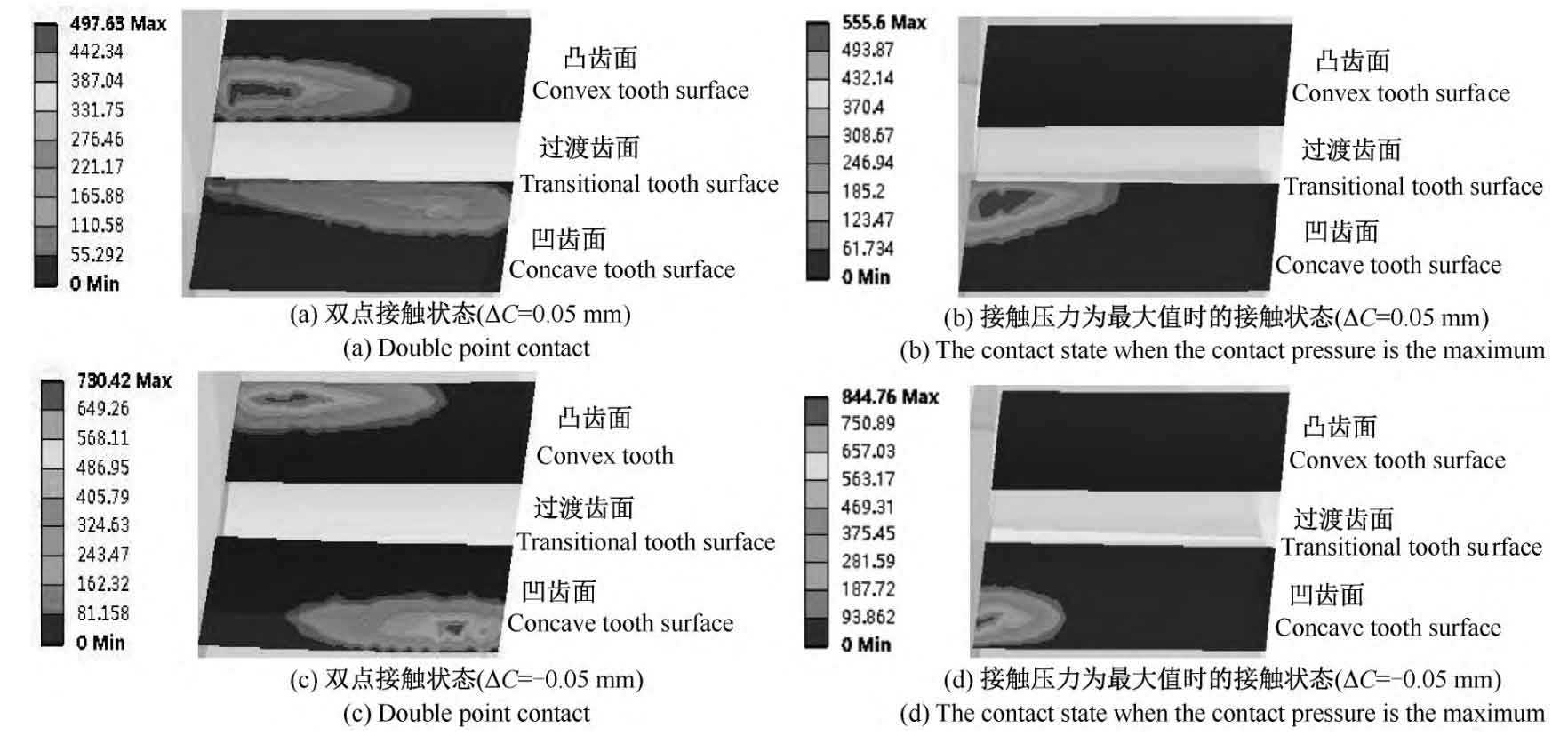

Figure 1 shows the contact state of tooth surface under bevel gear offset error. When Δ C = 0. At 05 mm, the two-point contact state of the tooth surface and the contact state when the contact pressure is the maximum are shown in Figure 1a and Figure 1b respectively; When Δ C = -0. At 05 mm, the two-point contact state of the tooth surface and the contact state when the contact pressure is the maximum are shown in Fig. 1c and Fig. 1d respectively.

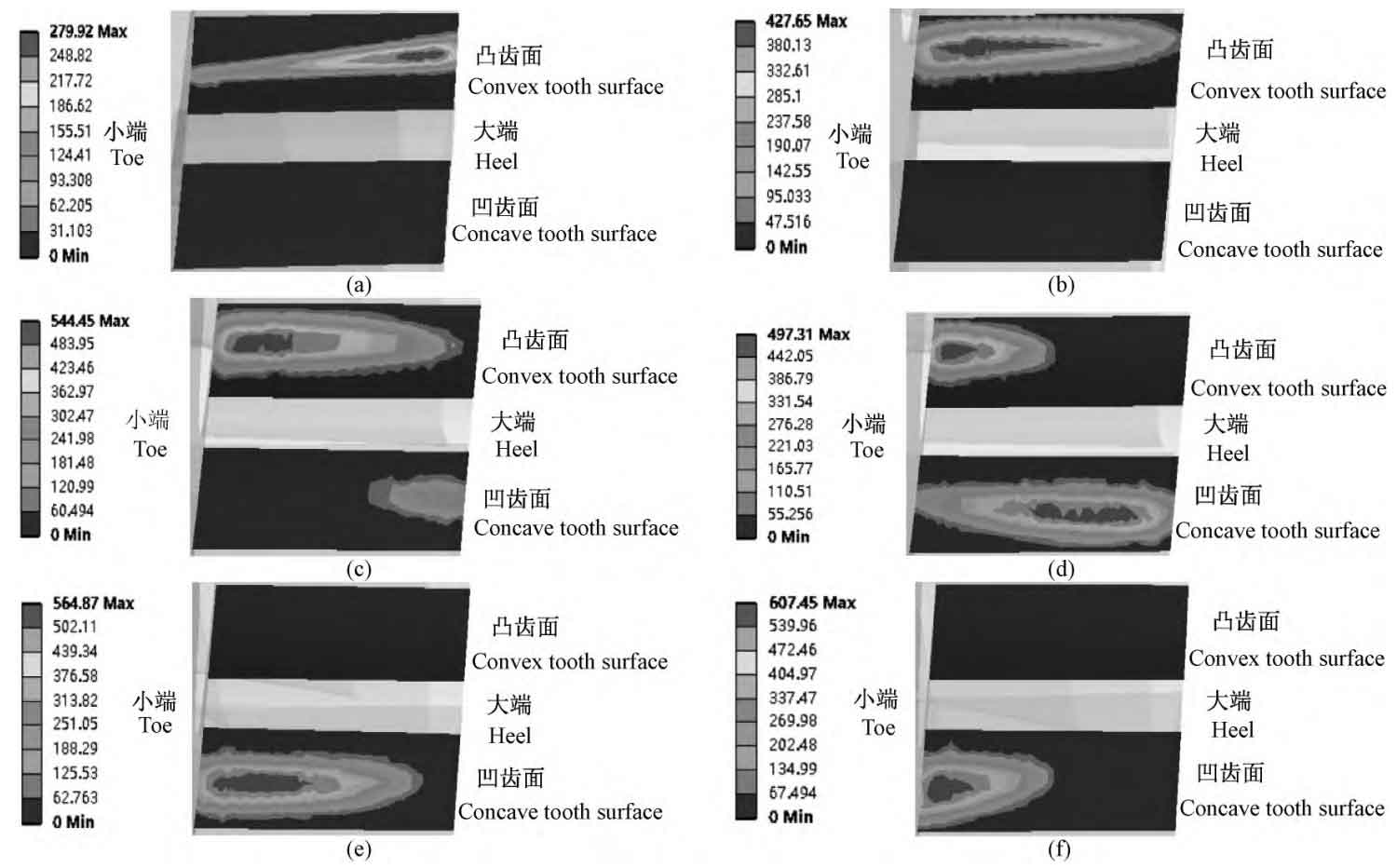

Comparing Fig. 2d, Fig. 2f and Fig. 1, it can be seen that the forward offset error will make the contact points of the convex and concave tooth surfaces of the bevel gear pair shift towards the direction of the transition tooth surface; The negative offset error makes the contact points of the convex and concave tooth surfaces of the bevel gear pair shift to the direction of the tooth top and the tooth root respectively. This is because when Δ C is the timing. The inner and outer bevel gears are away from each other, making the contact point of the tooth surface close to the transition tooth surface. When Δ When C is negative, the inner and outer bevel gears are close to each other, making the contact points of the convex and concave tooth surfaces far away from the transition tooth surface.

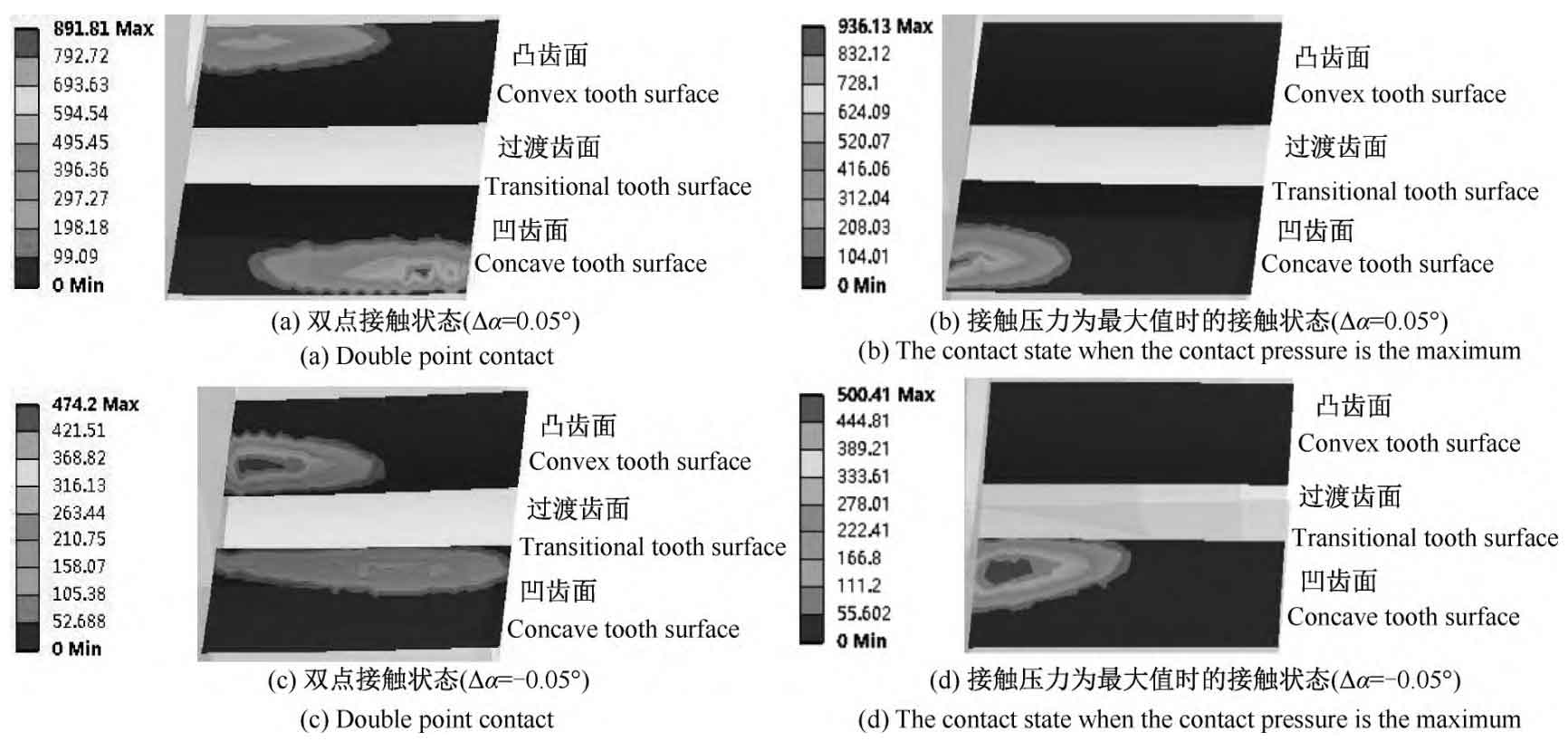

The contact state of tooth surface under nutation angle error is shown in Figure 3. When Δα= At 0.05 °, the two-point contact state of the tooth surface and the contact state when the contact pressure is the maximum are shown in Fig. 3a and Fig. 12b respectively; When Δα= - At 0. 05 °, the two-point contact state of the tooth surface and the contact state when the contact pressure is the maximum are shown in Fig. 3c and Fig. 3d respectively. Contrary to the influence rule of axial offset error, the positive nutation angle error makes the contact area on the convex tooth surface and the concave tooth surface shift to the direction of the tooth top and the tooth root respectively, and the negative nutation angle error makes the contact area shift to the direction of the transition tooth surface. This is because when Δα For timing, the inner and outer bevel gears are close to each other, so that the convex and concave contact points are far away from the transition gear surface. When Δα When it is negative, the two bevel gears are far away from each other, making the contact point of the tooth surface close to the transition tooth surface.

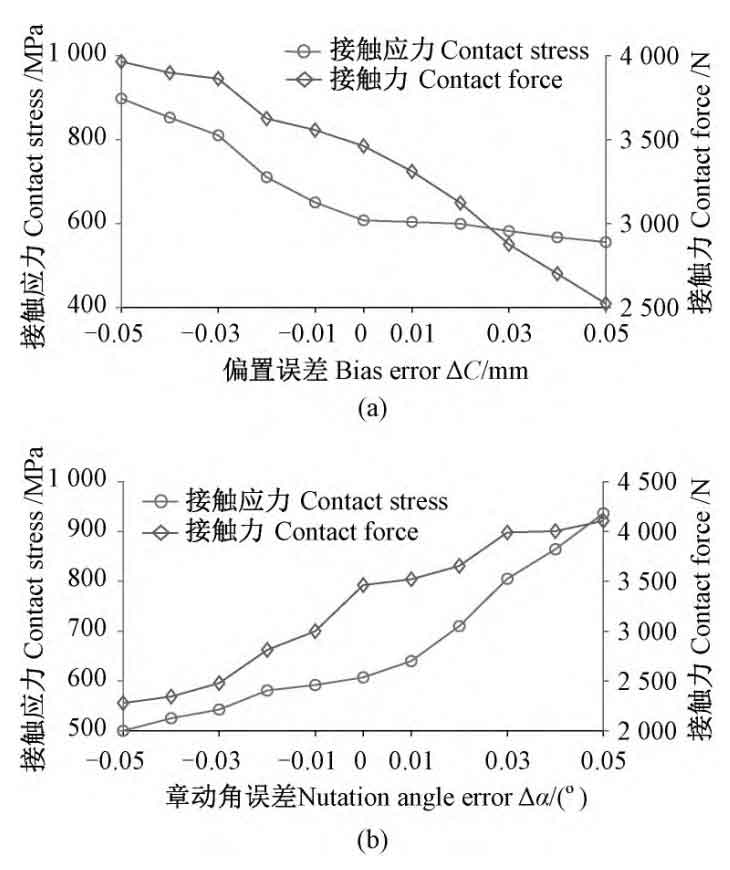

In order to further analyze the influence of installation error on the force on the tooth surface, the change curves of the maximum contact stress and the maximum contact force of the tooth surface under the bias error and nutation angle error are obtained through the finite element post-processing, and the results are shown in Figure 4.

It can be seen from Fig. 4a that when the offset error gradually increases in the negative direction, the maximum contact stress and maximum contact force on the tooth surface will increase accordingly; On the contrary, when the bias error increases in the positive direction, the two gradually decrease. However, the effect of nutation angle error on them is contrary to that of bias error, as shown in Figure 4b. Increasing the nutation angle error in the negative direction will reduce the maximum contact stress and the maximum contact force, while increasing the nutation angle error in the positive direction will make the two gradually increase. This is because the negative offset error and the positive nutation angle error make the contact point of the tooth surface of the bevel gear pair gradually close to the edge of the tooth, and the contact area becomes smaller, resulting in the gradual increase of the maximum contact stress of the bevel gear pair.

To sum up, compared with the positive offset error and the negative nutation angle error, the negative offset error and the positive nutation angle error make the tooth surface bear more force, which is more unfavorable to the bearing of bevel gears to some extent.